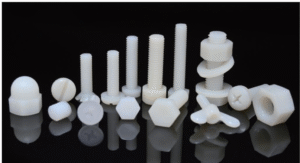

Main product

HOT PRODUCTS

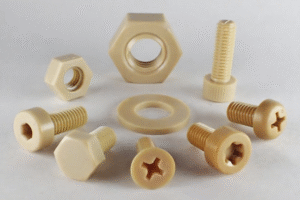

PEEK Hex head bolt

PEEK (polyetheretherketone) offers excellent chemical, heat, abrasion, flame retardancy, and hydrolysis resistance.

PP Countersunk Screws- Cross Recessed Phillips

PP (Polypropylene) is the lightest of general-purpose plastics and offers excellent bending resistance and high-frequency electrical insulation.

PVDF Pan Head Screws - Cross Recessed Phillips

PVDF (polyvinylidene fluoride) offers excellent chemical and weather resistance, as well as UV and aging resistance.

PA66 Hexagon nut

PA66 (Nylon 66) is a crystalline engineering plastic. It has excellent abrasion resistance, oil resistance and self-extinguishing properties (UL94V-2).

What does WellFastener do?

WellFastener is one of China’s earliest professional manufacturers of non-metallic fasteners. We specialize in the R&D, production, and sales of specialty non-metallic fasteners, including plastic screws, nylon screws, bolts, nuts, washers, hinges, and rivets, and also supply custom parts. Materials include PA66, PP, PVC, PPS, and PEEK, featuring corrosion resistance, UV resistance, high and low temperature resistance, and electrical insulation. Adhering to the principles of professionalism, precision, uniqueness, and innovation, we continuously develop new products, widely used in industries such as photovoltaics, semiconductors, aerospace, and automotive. We are committed to providing international customers with high-quality professional products and one-stop solutions for customized products.

Advanced High-Precision Non-Metallic Fasteners

WellFastener offers a comprehensive range of high-precision speed reducers and gearboxes, helping you achieve the optimal balance between design complexity and budget.

WHY CHOOSE US

- ISO9001 Quality Management System, GB/T14001 Environmental Management System, and GB/T45001 Occupational Health and Safety Management System.

- One-to-one support service by a technical team, quick response within a few hours.

- Comprehensive capabilities include in-house machining and integration of manufacturing resources across China.

- Our experienced engineering team and flexible production methods mean faster production and shorter lead times.

News Events

FAQ

What are plastic screws?

Plastic screws are fasteners made from various engineering plastics through injection molding or machining. Common materials include nylon (PA), polypropylene (PP), polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE), and PEEK.

What are the main advantages of plastic screws?

- Corrosion resistance: Resistant to acids, alkalis, salts, and other chemicals; does not rust.

- Lightweight: Weighs only 1/4 to 1/8 of metal.

- Electrical insulation: Non-conductive, ensuring electrical safety.

- Non-magnetic: Unaffected by magnetic fields.

- Low cost: Raw material and processing costs are generally lower

What types of plastic screw heads are available?

Classification by Head Shape:Head type, pan head, countersunk/flat head, semi-countersunk head, round/semi-round head, flat round/large round head, hexagonal head, washer head

How to choose the right plastic screw material?

- Nylon (PA6, PA66): A general choice; good overall performance in terms of strength, toughness, and wear resistance.

- Polypropylene (PP): Excellent chemical resistance (especially acids and alkalis); inexpensive.

- PVC: Good corrosion resistance and flame retardancy.

- PTFE: Extremely high chemical resistance, extremely low coefficient of friction (non-stick), high temperature resistance (-200°C to +260°C).

- PEEK: Extremely high strength, hardness, and heat resistance (long-term use >250°C), expensive.

Application Scenarios of Plastic Screws

Plastic screws, due to their unique material properties, play an irreplaceable role in many scenarios where metal screws are unsuitable.

1. Chemical and Environmental Protection Industries

2. 1. Food, Pharmaceuticals & Medical Devices

2. Electronics, Electrical & Telecommunications

3. Automotive & Transportation

4. Semiconductors & Photovoltaics

5. Specialty Industrial Applications

Are plastic screws insulated?

Yes, this is one of their key advantages. They are complete electrical insulators, making them ideal for electronic and electrical applications.

How to screw in a plastic screw?

- For self-tapping screws, a properly sized guide hole needs to be pre-drilled in the substrate.

- Use a manual torque screwdriver or a low-torque electric screwdriver.

- Ensure the screw is perpendicular to the hole.

- Tighten until you feel noticeable resistance, then tighten slightly more; do not force it all the way in.

Can you provide samples?

Most professional manufacturers (including us) offer sample services so you can test and verify the suitability of the product. You will usually need to bear the shipping costs.

Can non-standard sizes and colors be customized?

Yes. This is a major advantage of plastic parts. Various non-standard sizes, head shapes, and colors (by adding color masterbatch) of screws can be produced through injection molding or machining to meet your specific design requirements.

What is the delivery time for plastic screws?

- Standard parts: Usually in stock, delivery is fast (a few days to a week).

- Custom parts: take longer because they involve mold making or production scheduling (usually 2-4 weeks or longer).