For centuries, screws have been an integral part of human civilization, serving as essential fasteners in construction, machinery, and everyday objects.Let’s dive into the fascinating reasons behind the different types of screw heads and explore some of the most common, and even some special types of screw heads.

The Fundamental Purpose of a Screw Head

At its core, a screw head has two primary functions:

To provide a surface for a driving tool: This is where your screwdriver or drill bit interacts with the screw, allowing you to rotate and drive it into a material. The shape of the head dictates the type of screwdriver heads you’ll need.

To create a bearing surface: Once driven, the underside of the screw head presses against the material, providing clamping force and holding components together. The screw head shapes vary depending on the desired aesthetic or load distribution.

Why the Variety?

The diverse range of screw drive types and head shapes stems from several key factors:

Torque Transfer: Different head designs are better at transferring torque from the driving tool to the screw. Some designs minimize cam-out (the driver slipping out of the screw head), which can strip the screw or damage the workpiece.

Security and Tamper Resistance: For applications where security is paramount, special types of screw heads exist that require unique tools, making them difficult for unauthorized individuals to remove.

Aesthetics: In visible applications, the appearance of the screw head matters. Some designs are flush with the surface, while others offer a decorative look.

Ease of Use and Speed: For high-volume manufacturing, some screw heads are designed for quick and efficient driving with power tools.

Application-Specific Needs: The material being joined, the environment (e.g., corrosive, high vibration), and the required strength all influence the choice of screw head.

Common Screw Head Types and Their Uses

Let’s explore some of the most prevalent screw head types you’ll encounter:

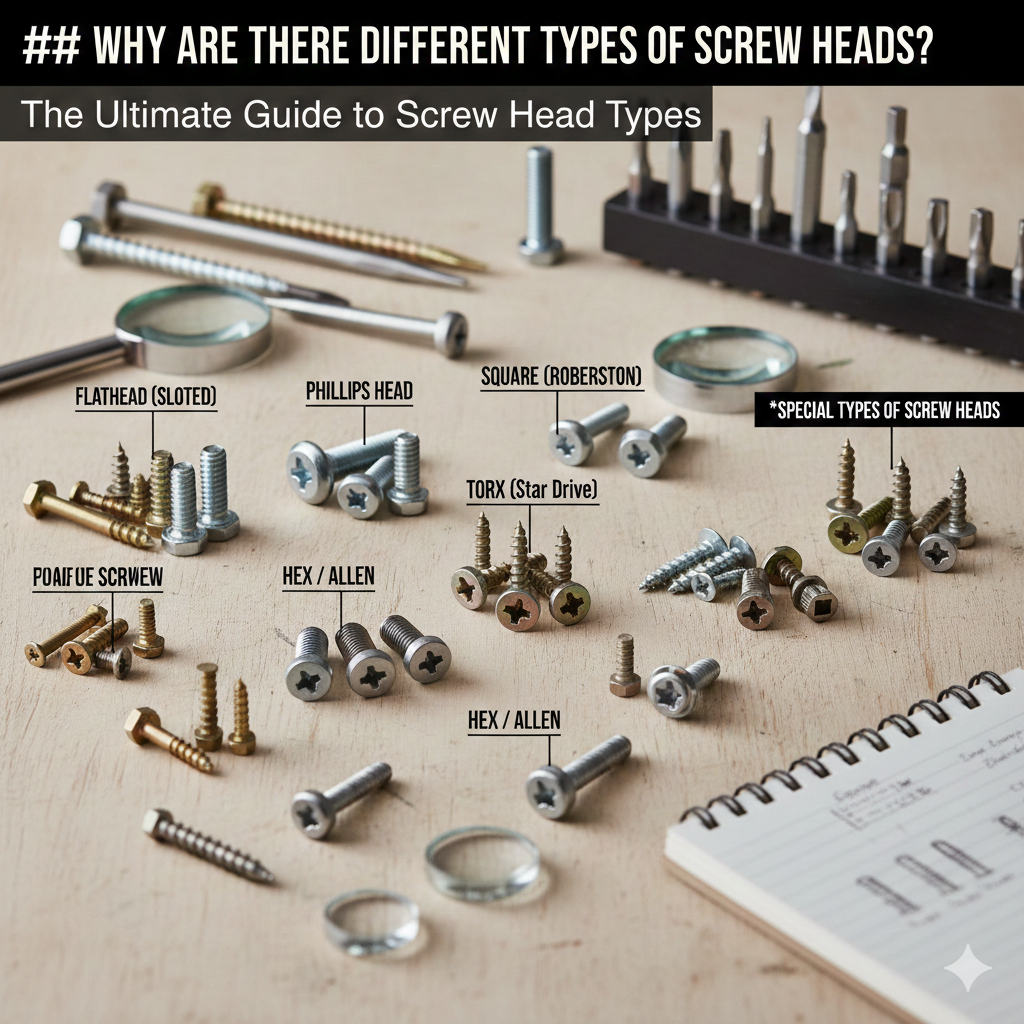

1. Flathead (Slotted)

This is perhaps the oldest and most recognizable screw head type, characterized by a single slot across the diameter of the head.

Pros: Simple design, can be driven with a wide range of tools (even a knife in a pinch!).

Cons: Prone to cam-out, especially with power tools, which can damage the screw head or the surrounding material.

Uses: Common in traditional woodworking, simple assemblies, and where a low-profile head is desired. It’s often debated in the phillips vs flathead screws context due to its historical prevalence.

2. Phillips Head

The Phillips head screw purpose was a game-changer when it was introduced. It features a cross-shaped recess in the head, designed to reduce cam-out compared to the flathead.

Pros: Better torque transfer than flathead, self-centering, widely available. There are even different phillips heads and phillips screw types (like Pozidriv, which is an improved Phillips design).

Cons: Still susceptible to cam-out at higher torques.

Uses: Extremely common in construction, electronics, and automotive applications. It’s one of the most recognized common screw heads.

3. Hex (Allen)

This head features a hexagonal recess, driven by an Allen key or hex bit.

Pros: Excellent torque transfer, minimal cam-out, can be driven with compact L-shaped wrenches. Often found in fastener heads requiring strong connections.

Cons: Requires a specific tool.

Uses: Furniture assembly, machinery, bicycle components, and applications requiring precise tightening. You might see a hex shaped screw in many industrial settings.

4. Torx (Star Drive)

The Torx head features a 6-point star-shaped recess. It’s known for its superior torque transfer and resistance to cam-out.

Pros: Virtually eliminates cam-out, allows for higher torque application, and extends tool life.

Cons: Requires a specific Torx driver.

Uses: Automotive, electronics, computer components, and wherever high torque and minimal cam-out are critical.

5. Square (Robertson)

Popular in Canada, the Robertson drive features a square-shaped recess.

Pros: Excellent cam-out resistance, easy to drive with one hand, driver bits tend to last longer.

Cons: Less common outside of Canada and specific industries.

Uses: Cabinetry, woodworking, decking, and general construction.

Other Important Considerations: Head Shapes and Fastener Heads

Beyond the drive type, the actual shape of the screw head also plays a crucial role. Some common screw head shapes include:

Pan Head: A slightly rounded, low-profile head with a large diameter, providing a good bearing surface.

Flat Head (Countersunk): Designed to sit flush with the surface of the material, requiring a countersink hole. This is the source of the flat head vs round head screws distinction.

Round Head: A domed head that sits above the surface, offering a decorative look.

Hex Washer Head: Combines a hex drive with an integrated washer, distributing pressure over a larger area.

Truss Head: A wide, low-profile domed head, ideal for attaching thin materials.

When you consider all the different kinds of screws and bolts, the head design is just one part of the equation. The thread type, material, and length also contribute to the fastener’s suitability for a particular application. Understanding the types of screws and their uses is essential for any DIY enthusiast or professional.

The Ever-Evolving World of Screws

The constant innovation in materials and manufacturing techniques means that new screw drive types and head designs continue to emerge. From tamper-resistant options like the Pentalobe (seen on Apple products) to specialized designs for composite materials, the world of fastener head types is always expanding.