Whether you are an automotive enthusiast, a DIY hobbyist, or a professional sourcing replacement fasteners, knowing how to measure a Screw is an essential skill. Accurate measurement of bolt dimensions involves three critical components: Diameter, Length, and Thread.

Essential Tools for Measuring Plastic Screw

To measure a bolt accurately, you will need:

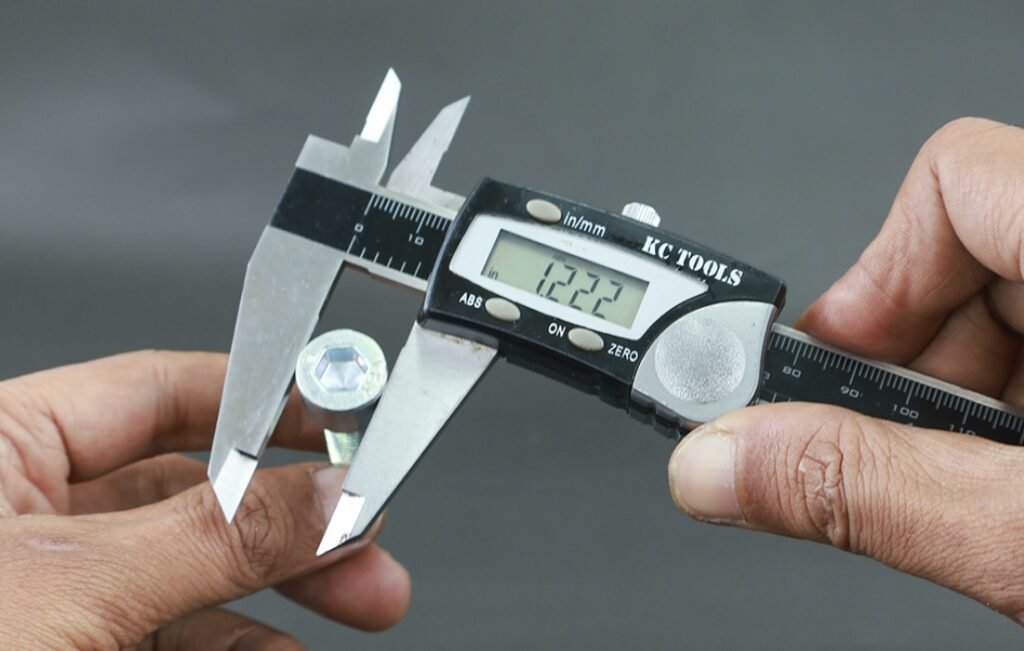

Digital Calipers (Digital Caliper): This is the best tool for measuring diameter and length, and the key instrument for how to measure bolt size with caliper.

Thread Pitch Gauge (Thread Gauge): Used to determine the pitch or Threads Per Inch (TPI). This is the most precise method for measuring bolt thread size.

Ruler or Tape Measure: Can be used for rough measurements of bolt length, but is less accurate than calipers.

📐 Part One: Measuring Screw Diameter (Screw Diameter)

The bolt diameter is one of the most critical dimensions of a bolt, used to determine how to find bolt size.

1. Measuring the Major Diameter

The Major Diameter is the largest diameter of the threads, measured across the outer peaks. To accurately measure how to measure a bolt diameter:

Use the calipers and gently clamp the jaws across the highest points (crests) of the threads.

Record the reading. The bolt’s Nominal Size is equal to its Major Diameter.

2. Metric vs. Imperial (US Standard)

Understanding which system you are measuring is vital for comprehending how to read bolt sizes:

| System | Unit of Measurement | Typical Size Designation |

| Metric | Millimeters (mm) | M (e.g., M8, M10) |

| Imperial (US Standard) | Inches (in) | Fractions or Gauge Numbers (e.g., $1/4″$, #10) |

For example, to determine how to measure bolt size m8, you will find its Major Diameter is approximately 8mm.

Part Two: Measuring Screw Length (Screw Length Measurement)

How to measure a bolt length depends on the type of bolt head. The bolt length is the distance from the bearing surface to the end of the bolt.

| Bolt Head Type | Starting Point for Measurement | Bolt Length |

| Hex Head | The bearing surface directly under the head | Measured from the bearing surface to the bolt tip. |

| Pan/Round Head | The bearing surface directly under the head | Measured from the bearing surface to the bolt tip. |

| Countersunk Head | The top surface of the bolt head | Measured from the top surface to the bolt tip. |

Summary: Except for countersunk bolts, the height of the bolt head is generally not included in the bolt length measurement.

Part Three: Measuring Thread Size (Measure Bolt Thread Size)

This is the most challenging part of how to measure a bolt thread, as it determines if the bolt will match the correct nut. This step is crucial for how to determine nut size.

1. Metric Thread

Measurement Target: Pitch, which is the distance between adjacent thread peaks (measured in millimeters).

Method:

Use a thread gauge (recommended) and gently place it against the threads until a perfect match is found.

If using calipers, you can measure the total distance spanned by 10 thread peaks and then divide by 10 to get the average pitch.

Metric Labeling Example: M8 *1.25. This means Major Diameter 8mm, Pitch 1.25mm.

2. Imperial Thread (US Standard Thread)

Measurement Target: TPI (Threads Per Inch), which is the number of threads within a 1-inch length.

Method:

Use a thread gauge (recommended) for direct fitting.

Alternatively, use a ruler to count how many thread peaks occur within a 1-inch length.

Imperial Labeling Example: 1/4-20$. This means Major Diameter 1/4 inch, with 20 threads per inch.

Conclusion: How To Determine Bolt Size

To fully ascertain the bolt dimensions, you must combine all three measurements. For instance, a complete specification might be:

This denotes: Major Diameter 10mm (M10), Pitch 1.5mm, and bolt length 50mm.

By mastering the techniques for measuring diameter, length, and how to measure a bolt size with threads, you can confidently match and select the correct fasteners, avoiding engineering issues caused by incorrect sizing.

Special Precautions for Measuring Plastic Threads

Caution: Handle the plastic screws gently throughout the process to avoid scratching or damaging the plastic threads.

Molding Flaws: Injection-molded plastic screws may have flash or parting lines. Try to measure in areas that are clear of these defects.

Understanding Tolerance: Plastic screws may not have the same dimensional precision as metal screws; slight deviations from the ideal size are normal.

Thread Types: Some self-tapping plastic screws use unique thread designs (e.g., trilobular or high-low threads) which are not compatible with standard machine threads (like Metric or UNC). Ultimately, a fit-check with the intended mating component or a verified nut is the required final confirmation.