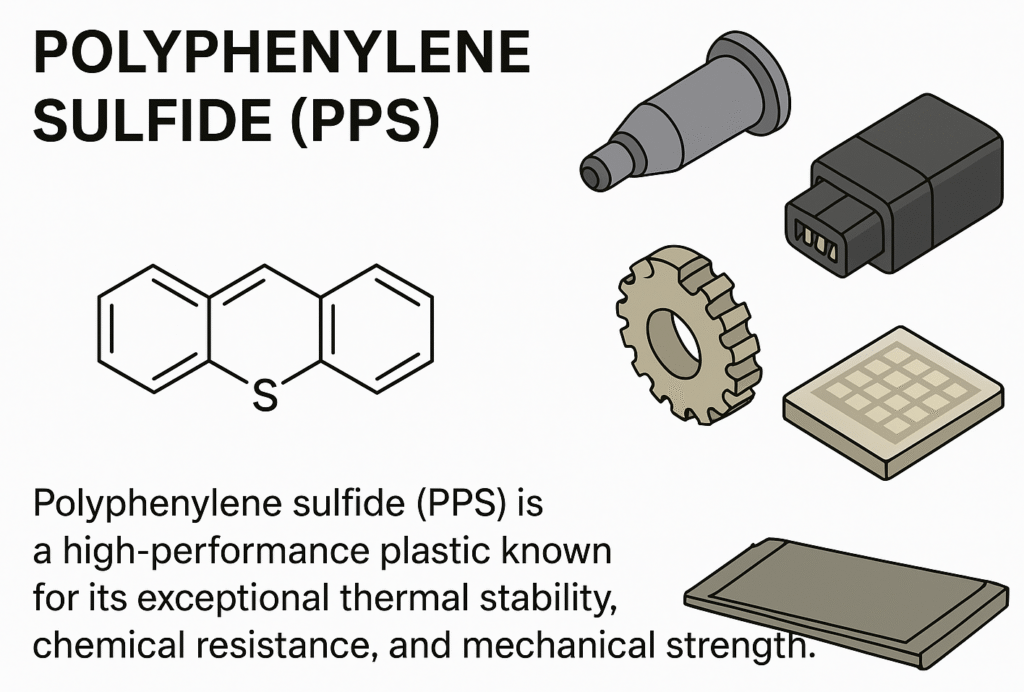

Polyphenylene Sulfide (PPS) Overview

Polyphenylene Sulfide (PPS), often referred to simply as polyphenylene or polyphenylene sulfide PPS, is a high-temperature, semi-crystalline engineering thermoplastic. Because of its excellent durability and thermal resistance, polyphenylene sulfide plastic is frequently selected for demanding applications where other plastics cannot perform.

Main Types of Polyphenylene Sulfide (PPS)

Based on Composition (Fillers – Most Common in Use),In practical applications, the vast majority of PPS are modified or composite materials to improve specific properties:

| Type | Composition | Key Benefit |

| Unfilled PPS | Pure PPS resin. | Used when optimal electrical or chemical properties are required, and strength is secondary. |

| Glass Fiber Reinforced PPS | PPS + Glass Fibers (typically 30% to 60%). | Standard Industrial Grade. Significantly increases strength, stiffness, heat deflection temperature (HDT), and dimensional stability (e.g., automotive structural parts). |

| Mineral/Carbon Fiber Filled PPS | PPS + Mineral fillers (e.g., talc) or Carbon Fibers. | Mineral fillers enhance dimensional accuracy. Carbon fibers increase conductivity and ultimate stiffness (e.g., specialized electronic casings). |

| Lubricated PPS | PPS + PTFE (Teflon) or Silicone. | Improves wear resistance and self-lubricating properties for moving parts like bearings, gears, and bushings. |

Key Properties PPS Plastic

The magic of PPS plastic lies in its ability to maintain its integrity and performance where other materials simply cannot.

- Exceptional High-Temperature Resistance: PPS boasts an impressive continuous service temperature, often exceeding 200°C (392°C) and with a polyphenylene sulfide melting point that allows for use in very hot environments. This is a primary reason for its popularity.

- Outstanding Chemical Resistance: It is highly resistant to a very broad range of chemicals, including acids, bases, and organic solvents, even at elevated temperatures. This makes it a go-to material in harsh chemical processing.

- Inherent Flame Retardancy: PPS is naturally flame retardant (UL 94 V-0 rating), often without the need for additional flame retardant additives. This is a critical safety feature in many applications.

- Excellent Mechanical Strength & Stiffness: PPS offers good tensile strength and stiffness, which can be further enhanced when compounded with glass fibers or other fillers, creating robust PPS plastic material for structural components.

- Dimensional Stability: It exhibits very low creep (deformation under long-term stress) and excellent dimensional stability, even at high temperatures.

- Good Electrical Insulation Properties: It maintains its dielectric properties over a wide range of temperatures and frequencies, making it suitable for electrical components.

Polyphenylene Sulfide Applications: Where PPS Sh

The unique combination of properties makes polyphenylene sulfide invaluable across a multitude of industries. The polyphenylene sulfide market is driven by these demanding applications:

- Automotive Industry: A significant portion of polyphenylene sulfide applications are found in under-the-hood automotive components. These include fuel system parts, pumps, valves, ignition systems, and exhaust gas recirculation (EGR) valves, where resistance to heat, chemicals, and automotive fluids is crucial.

- Electrical & Electronics: Due to its excellent electrical insulation and flame retardancy, PPS is used for connectors, switches, relay components, coil bobbins, lamp sockets, and various encapsulations.

- Industrial & Mechanical: It’s employed in industrial pumps, valves, compressor components, impellers, and heat exchangers that require resistance to aggressive media and high temperatures.

- Coatings: Polyphenylene sulfide coating (or PPS coating) is also used for corrosion protection on metal parts, offering a durable, heat-resistant, and chemical-resistant barrier. This is a specialized, but growing segment of the market for pps polymer.

- Filtration (PPS Fabric): In some industrial filtration systems, PPS fabric is used for filter bags in hot gas filtration, thanks to its high-temperature and chemical resistance.

Polyphenylene Sulfide (PPS): Advantages, Disadvantages

Advantages and Disadvantages of PPS

The unique characteristics of Polyphenylene Sulfide (PPS) make it a high-demand engineering plastic, despite some trade-offs.

| Aspect | Advantage | Disadvantage |

| Thermal & Mechanical | Exceptional Thermal Stability: High continuous service temperature (over 200°C). High Stiffness & Dimensional Stability. | Higher Cost: Significantly more expensive than general-purpose engineering plastics. Relatively Brittle: Unfilled resin has low impact strength/toughness. |

| Chemical & Electrical | Outstanding Chemical Resistance: Highly resistant to a wide range of acids, bases, and solvents at high temperatures. Excellent Electrical Insulation. | UV Sensitivity: Poor resistance to prolonged UV exposure (sunlight). |

| Safety & Processing | Inherent Flame Retardancy (Typically UL 94 V-0 without additives). | Narrow Processing Window: Requires strict control over high processing temperatures. |

The Future of PPS

The polyphenylene sulfide market continues to grow as industries push the boundaries of performance and demand materials that can withstand more extreme conditions. As innovation in electric vehicles, advanced electronics, and energy systems progresses, the need for robust, reliable, and high-temperature resistant materials like PPS plastic material will only increase. While factors like polyphenylene sulfide prices can be higher than general-purpose plastics, its long-term performance and reliability often justify the initial investment.

In summary, when you need a plastic that can take the heat, shrug off chemicals, and maintain its form, polyphenylene sulfide is often the answer.

FAQ

PPS Screws, Nuts and Flat Washers

wellfastener offer a range of PPS Fasteners. Find out more by selecting a product below: