PTFE-coated components are widely used in industries requiring low friction coating, chemical resistant coating, and anti-corrosion coating。This makes PTFE-coated components essential in industrial, chemical, and food-processing applications.

PTFE Coated Overview

A PTFE coating is a layer of PTFE coating material applied to a substrate to improve durability, reduce friction, and prevent corrosion. It can be applied via:

- PTFE coating spray or Teflon PTFE spray coating

- Powder coating (teflon powder coating)

- Paint coating (PTFE paint coating, Teflon paint coating)

- Industrial PTFE coating or Xylan coating for heavy-duty applications

The PTFE coating process ensures a uniform layer of PTFE coating material over metals, fiberglass, or other substrates. Common PTFE-coated materials include PTFE coated stainless steel, PTFE coated bolts, and PTFE coated fiberglass.

Key properties of PTFE Coated

- Excellent chemical resistant coating

- Low friction coating for moving parts

- Non stick coating for industrial and food applications

- Anti corrosion coating for metals and alloys

- Can withstand high temperatures

- Durable and long-lasting

- Compatible with complex geometries

PTFE Coated Advantages

The functional advantages of coating PTFE are categorized into three main areas:

- Corrosion & Chemical Resistance: Teflon ptfe coating acts as a supreme anti corrosion coating and chemical resistant coating against salt water, acids, caustics, and solvents.

- Low Friction & Non-Stick: The low friction coating reduces drag, eliminates stick-slip, and acts as a dry lubricant, crucial for preventing seizing.

- Thermal Stability: Maintains integrity across a vast temperature range (200°C to 260°C

- Wear Prevention: The slipperiness of the PTFE coat prevents metal-to-metal wear and anti-galling.

Companies often offer PTFE coating services to apply custom solutions. Brand-specific options like Xylan coating are also available as alternatives to PTFE coating vs teflon coating。

PTFE Coated Applications

The versatility of PTFE coated products makes them indispensable across a multitude of industries (ptfe applications):

- Industrial Fasteners: PTFE coated bolts, nuts, and washers in chemical, marine, and oil & gas sectors.

- Chemical Processing: Reactor vessels, pipes, valves, and pump components require chemical resistant coating.

- Food & Beverage: Conveyor belts, molds, and processing surfaces use PTFE coatings for non-stick properties and resistance to cleaning agents.

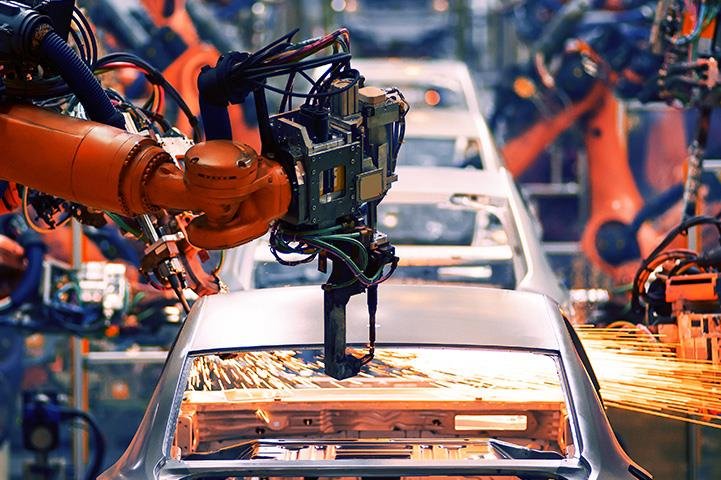

- Automotive/Aerospace: Bushings, seals, and gaskets requiring low friction and high-temperature resistance.

- Textile & Paper: Rollers and machinery components to prevent material sticking (non stick coating).

- Cookware: The classic Teflon coating application.

- Specialized Products: PTFE coated fiberglass (or ptfe fiberglass coating) for conveyor belts and heat seals.

Case Study: PTFE Coated A2 Stainless Steel Fasteners

One of the most vital ptfe applications is in industrial assembly, particularly on threaded components.

| Component | Standard Material | PTFE Coated Application |

| A2 Stainless Steel Fasteners | A2 (Type 304) Stainless Steel | PTFE coated bolts (and nuts) used in offshore oil and gas platforms, chemical plants, and marine environments. |

| Problem Solved | Stainless steel is prone to galling (cold welding) and crevice corrosion in high-salinity or chlorine-rich atmospheres, making disassembly nearly impossible and damaging the fasteners. | The PTFE coating on stainless steel provides a smooth, sacrificial layer that eliminates metal-to-metal contact, preventing galling (anti-galling). It seals the fasteners, offering enhanced anti corrosion coating protection that far exceeds the base stainless steel alone. |

| Result | Significantly extended lifespan of the fasteners, easy installation with lower, more consistent torque, and guaranteed easy disassembly, drastically reducing maintenance time and costs in critical infrastructure. |

The combination of the strong A2 stainless steel core with the chemical and friction benefits of the PTFE coat is essential for reliable long-term service in the world’s harshest environments.

Conclusion

PTFE-coated components are indispensable for industries requiring non-stick coating, low friction coating, and chemical-resistant surfaces. From PTFE-coated A2 stainless steel fasteners to PTFE coated fiberglass and machinery parts, understanding what is PTFE material and the PTFE coating process is key to improving performance, durability, and maintenance efficiency.