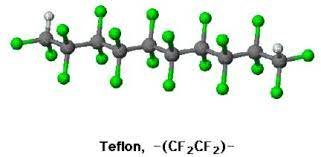

Polytetrafluoroethylene(PTFE) is a synthetic fluoropolymer, a plastic material renowned globally for its exceptional non-stick, chemical-resistant, and low-friction properties. It is best known by the famous brand name, Teflon , owned by Chemours (a spin-off of DuPont).

Polytetrafluoroethylene Overview, Design, and Forms

Polytetrafluoroethylene is a high-molecular-weight polymer consisting entirely of carbon and fluorine atoms, forming an exceptionally strong and stable bond.The resulting PTFE molecule creates a dense, inert, and electrically non-polar surface.

A. Design and Forms

PTFE plastic is utilized in two primary forms:

- Molded/Machined Parts: Polytetrafluoroethylene resin is compressed and sintered to form solid shapes (rods, tubes, sheets), which are then machined into products like seals, gaskets, and bearings.

- Coatings: Fine PTFE powder is mixed with a binder, applied as a liquid (ptfe teflon spray or polytetrafluoroethylene coating), and cured at high temperatures to create thin ptfe coatings on metal substrates.

B. Expanded PTFE (ePTFE)

A variant, ePTFE (expanded PTFE), is created by rapidly stretching PTFE. This results in a porous, micro-structure material used in medical applications (e.g., vascular grafts, sutures), filtration, and weatherproof fabrics.

Polytetrafluoroethylene product

As a raw material, PTFE is supplied in several forms for manufacturing:

| Form | Key Dimensional Parameter | Importance |

| Rods / Billets | Diameter and Length | Used for machining precision parts (bushings, seals). |

| Sheets / Plates | Thickness and Area | Used for cutting gaskets, sliding pads, and liners. |

| Film / Tape | Thickness (in mils or micrometers) | Used for wire insulation and non-stick sealing tape. |

| Powder / Spray | Coating Thickness (in micrometers) | Defines the durability and performance of a ptfe coating. |

Key Characteristics and Properties

The polytetrafluoroethylene ptfe properties are exceptional, making it a unique teflon plastic material among polymers:

| Property | Value/Description | Significance |

| Coefficient of Friction | Extremely Low (0.05 to 0.20) | Lowest of all solids, crucial for non-stick and low friction applications. |

| Chemical Resistance | Near Universal Inertness | Resists virtually all chemicals, acids, and bases (except molten alkali metals). |

| Thermal Range (PTFE Temperature Range) | 200°C to 260°C | ptfe temperature rating is the broadest of any conventional polymer. |

| Melting Temperature | PTFE Melting Point 372°C | High thermal stability compared to common plastics. |

| Density | PTFE Density 2.1 to 2.3g/cm³ | High for a plastic, reflecting the dense packing of C and Fatoms. |

| Dielectric Strength | Excellent | Superb electrical insulator, even at high frequencies. |

Polytetrafluoroethylene(PTFE )Uses

The robust ptfe material properties make it indispensable in demanding environments:

- Cookware/Bakeware: Non-stick coating on pans and trays.

- Chemical Industry: Liners for tanks and pipes, ptfe coatings for pumps and valves, gaskets, and seals exposed to highly corrosive chemicals.

- Electrical: Wire and cable insulation (due to high dielectric strength and heat resistance).

- Automotive/Aerospace: Bearings, bushings, seals, and fuel lines requiring low friction and high temperature tolerance.

- Medical: Components for surgical instruments and implants (using ePTFE).

Advantages vs Disadvantages

| Category | Advantages (Pros) | Disadvantages (Cons) |

| Performance | Unrivaled chemical resistance and low friction. Extremely wide PTFE temp range. Non-toxic and food-safe. | Cold Flow (Creep): Tends to deform permanently under sustained load, especially at high temperatures. |

| Manufacturing | Excellent electrical properties. Available as spray teflon ptfe for easy application. | Difficult to Bond: Low surface energy makes adhesive bonding challenging. |

| Environmental | High purity, excellent weathering resistance. | PFAS Concern (Historical): PFOA and PFOS, historically used in the manufacturing process (not in the final PTFE), are now heavily regulated/banned. Modern PTFE production is PFOA-free. |

Development Space

The future of polytetrafluoroethylene lies in composite materials:

- Filled PTFE: Blending PTFE with glass fiber, carbon, or bronze to improve hardness, stiffness, and reduce creep, expanding its use in structural bearings.

- Modified Fluoropolymers (PFA/FEP): These materials offer similar properties but are melt-processable (unlike PTFE), allowing for cheaper and more complex molded parts.

- Advanced Coatings: Developing multi-layer ptfe coatings that integrate ceramics for enhanced scratch resistance and durability in consumer and industrial applications.

Conclusion

PTFE (Polytetrafluoroethylene), commonly known as Teflon, remains one of the most versatile industrial materials ever created. With its unique combination of chemical inertness, non-stick behavior, thermal stability, and low friction, PTFE continues to find new applications across industries—from cookware to aerospace.

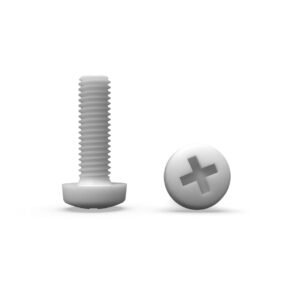

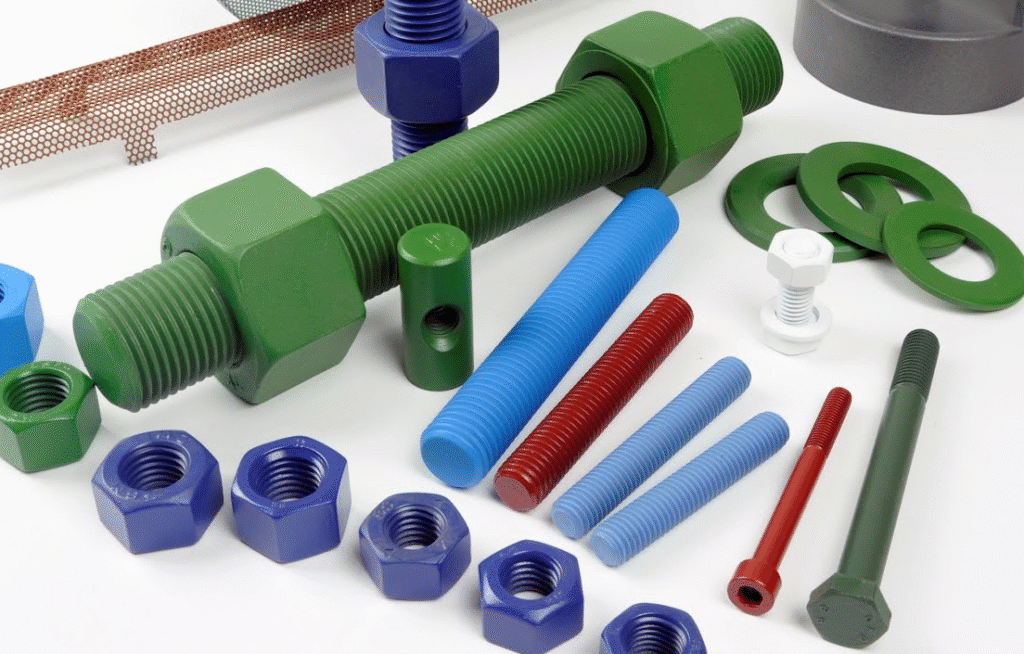

PTFE Screws, Nuts and Flat Washers

PA66+GF/Nylon fiberglass thread rod

$1.00PTFE Cross pan head screw

$1.00PTFE Crosscounter sunk head screw

$1.00PTFE Flat washer

$1.00PTFE Hex nut

$1.00PTFE Hexagon head bolt

$1.00