1. Definition and Structure: Hex Head vs. Hex Screw

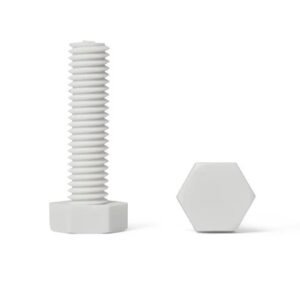

Hex Bolt formally known as the Hexagon Head Bolt or Hex Head Bolt, is a fastener with a six-sided head designed for installation using a wrench, socket, or spanner. Thanks to its geometry, the hexagon head allows a tool to grip from multiple angles and ensures excellent torque delivery.

1.Common alternative names include:

- Hex Head Bolt / Hex Bolt

- Hex Head Screw / Hex Screw

- Hexagon Head Bolt

- Hex Cap Bolt

- Hex Machine Bolt

2. Drive Type

Unlike pan head screws, which use slots or recesses (Phillips, Torx), Hex Head Bolts are externally driven. The six flat sides allow a standard wrench or socket to apply significant torque without cam-out (slipping).

2.Materials

The performance of the Hex Bolt is primarily defined by its material and grade (strength rating).

| Material Category | Specific Material / Grade | Primary Advantages | Typical Application Scenarios |

| Metals: Standard Steel | Carbon Steel (Grades 5, 8 / Metric 8.8, 10.9) | High tensile strength; high load-bearing capacity; cost-effective. | Structural construction, heavy machinery assembly, automotive engine mounts. |

| Metals: Stainless Steel | Stainless Steel (Type 304 / A2) | Good general corrosion resistance; widely available; good ductility. | General outdoor fixtures, standard industrial use, non-critical food processing. |

| Stainless Steel (Type 316 / A4) | Excellent resistance to chlorides, salt spray, and sulfuric acids (Marine Grade). | Coastal/marine environments, chemical plants, harsh outdoor applications. | |

| Metals: Lightweight | Aluminum (Specific Alloys) | Extremely low density (lightweight); high strength-to-weight ratio. | Aerospace non-critical joints, high-performance racing components, bicycle frames. |

| Polymers (Plastic Fasteners) | Nylon (Polyamide, PA) | Electrical and thermal insulation; excellent chemical resistance (non-oxidizing); non-magnetic. | Electronics assembly, circuit board mounting, chemical mixing vats, damp environments. |

| Polypropylene (PP) | Very lightweight; excellent resistance to strong acids and bases; lowest density among common plastics. | Chemical processing in low-load applications, laboratory equipment, filtration systems. | |

| PVDF (Polyvinylidene Fluoride) | Superior chemical and high-temperature resistance for a plastic; UV stability. | Semiconductor wet benches, aggressive chemical piping, high-end chemical processing equipment. |

3. Key Characteristics

- High Tensile Strength: Steel Hex Bolts are designed to be strained axially (pulled tight), making them ideal for creating highly tensioned, reliable joints.

- Temperature Stability: Steel bolts maintain their integrity across wide temperature ranges, crucial for applications like engine parts.

- Corrosion Protection: Most carbon steel bolts require surface treatment (e.g., hot-dip galvanizing, zinc plating, or fluoropolymer coating) to prevent rust and maintain structural integrity.

4. History and Usage

1. History

The hexagonal head design is an old and enduring design solution. It became the industry standard in the 19th century because it offered the highest efficiency: it is the easiest geometric shape to machine (compared to square heads) and provides the optimal balance between the number of sides (allowing for easy wrench positioning) and material use. The standardization of bolt threads (like the Unified Thread Standard and Metric threads) cemented the Hex Bolt as the backbone of modern mechanical assembly.

2. Usage Scenarios

The Hex Bolt is irreplaceable in applications requiring high clamping force and reliability:

- Structural Engineering: Connecting beams and columns in skyscrapers and bridges.

- Heavy Machinery: Fastening chassis, frames, and large assemblies in construction and mining equipment.

- Automotive: Engine mounts, suspension components, and high-stress chassis connections

5. Advantages and Disadvantages

| Advantages | Disadvantages |

| High Clamping Load | Provides excellent pre-load and shear strength. |

| External Drive Simplicity | Easy to drive with standard wrenches/sockets; no specialized recess required. |

| Versatility | Available in all standard grades and materials. |

| Reliable Standardization | Highly regulated dimensional and strength standards globally. |

6.Future Development and Market Space

The Hex Bolt is a mature technology, but innovation continues, driven by new material science and smart technologies:

- Smart Fasteners: Developing Hex Bolts with integrated sensors (piezoelectric or strain gauges) to monitor and report real-time tension or loosening, crucial for mission-critical structures like bridges and wind turbines.

- Advanced Coatings: Moving beyond simple galvanization to using ceramic or composite coatings (like zinc-nickel alloys) for extreme corrosion and abrasion resistance in offshore and chemical processing environments.

- Lightweighting: Utilizing high-strength, lightweight alloys (e.g., titanium or advanced aluminum) for specialized aerospace and high-end automotive applications where weight reduction is paramount, while retaining the familiar and robust Hex Head Bolt geometry.

- Additive Manufacturing: Exploring 3D printing of customized Hex Bolts from super-alloys for specialized, low-volume, high-performance applications.

Hex Bolt Product

CPVC Hexagon head bolt

$1.00PA66 GF30 Hex head Bolts

$1.00PA66 Hexagon head bolt

$1.00PC Hexagon head bolt

$1.00PEEK Hexagon head bolt

$1.00PFA Hexagon head bolt

$1.00PP Hexagon head bolt

$1.00PPS Hexagon head bolt

$1.00