What is Perfluoroalkoxy Alkanev(PFA)?

Perfluoroalkoxy Alkane (PFA) is a high-performance fluoropolymer,renowned for its exceptional chemical resistance, high-temperature stability, and non-stick properties. Perfluoroalkoxy Alkane Polymer is a pfa polymer that shares the chemical backbone of PTFE but incorporates perfluoroalkoxy side chains,It is often considered the next evolutionary step beyond PTFE (Polytetrafluoroethylene, commonly known as Teflon).

PFA stands for Perfluoroalkoxy Alkane, sometimes called perfluoroalkoxy or perfluoroalkoxy alkanes.

It refers to a family of fluoropolymer PFA materials formed by polymerizing tetrafluoroethylene (TFE) with perfluoroalkyl vinyl ether (PFAVE) comonomers.

- PFA abbreviation / PFA acronym: PerFluoroAlkoxy

- PFA full form: Perfluoroalkoxy alkane

- PFA meaning chemical: A fully fluorinated polymer similar to PTFE but melt-processable

- PFA definition: A high-purity fluoroplastic with exceptional chemical and thermal resistance

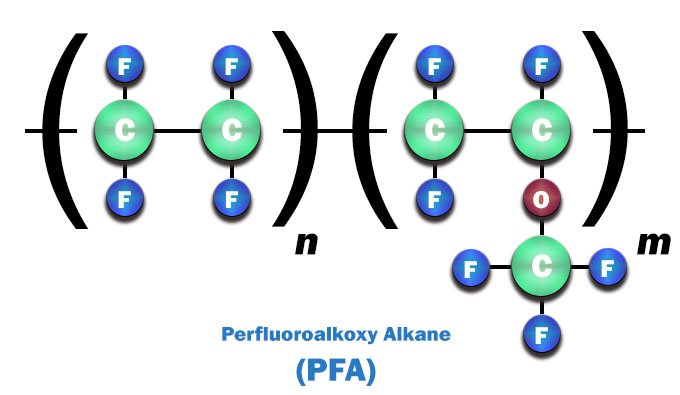

Chemical Structure of PFA

The superior performance of PFA material is rooted in its chemistry.

- Backbone: Like PTFE, the PFA structure is a chain of carbon atoms fully saturated with fluorine atoms. The (C–F) bonds are extremely strong, imparting unparalleled chemical inertness.

- Side Chains: PFA is defined by its perfluoroalkoxy side chains . These groups prevent the chains from packing together too tightly, lowering the overall crystallinity compared to PTFE, which enables melt flow.

- Classification: PFA is a member of the fluoropolymer PFA family and, chemically, is a type of PFAS (Per- and Polyfluoroalkyl Substances).

Key PFA Properties

| Property | Value (Typical) | Significance |

| PFA Melting Point (Tm) | 305°C to 310°C (melting temperature of PFA) | Extremely high for a thermoplastic; lower than PTFE but allows for melt processing. |

| PFA Temperature Range | Continuous service up to 260°C | Maintained strength and electrical properties under severe heat. |

| Chemical Resistance | Near-universal | Resistant to virtually all chemicals, including concentrated acids, bases, and organic solvents. |

| Purity | Extremely high | Very low extractables, ideal for semiconductor and pharmaceutical uses. |

| Surface | Non-stick and low friction. | Inherits PTFE’s best surface qualities. |

| Flexibility | More flexible than PTFE. | Easier to bend and install in tubing and pfa lining applications. |

Applications and Use Scenarios

Due to its high cost and exceptional performance, PFA resins are reserved for critical, non-negotiable applications:

- Semiconductor Industry: PFA is the material of choice for chemical transport, tubing, pumps, and valves handling ultra-pure water and highly corrosive etching chemicals, where any contamination is unacceptable.

- Chemical Processing: Used for pfa lining of pipes, vessels, and reactors to protect metal components from aggressive media, extending equipment lifespan.

- Electrical: High-temperature wire and cable insulation, due to its excellent dielectric properties and thermal stability within a wide pfa temperature range.

- Cookware/Molding: High-end, durable, non-stick coatings where high curing temperatures are required.

Advantages and Disadvantages

| Advantages (Why choose PFA or pfa fluoropolymer) | Disadvantages (Why not choose PFA) |

| Melt Processable | Extremely high cost (significantly more expensive than PTFE or FEP). |

| Near-Universal Chemical Resistance | High density, making parts heavier than those made from PE or PP. |

| Excellent Creep Resistance (Better than PTFE) | Difficult to bond or adhere to other materials due to its non-stick nature. |

| Superior Thermal Stability (High pfa melting point) | Requires specialized equipment for high-temperature processing. |

| High Dielectric Strength and Purity |

Frequently Asked Questions About PFA

PFA Screws, Nuts and Flat Washers

PFA Cross counter sunk head screw

$1.00PFA Flat washer

$1.00PFA Hexagon head bolt

$1.00PFA Hexagon nut

$1.00PFA Hexagon socket head screw

$1.00PFA Slotted cheese head screw

$1.00