Polyamide (PA) Overview

Polyamide (PA), commonly known as Nylon, is a synthetic polymer renowned for its high strength, durability, and wide range of applications. The number suffix (pa6, pa66, 46, 12) indicates the monomer composition and structure, which significantly dictates the final properties and applications of the material. A common question is is polyamide the same as nylon? Yes, Nylon is the trade name for Polyamide.

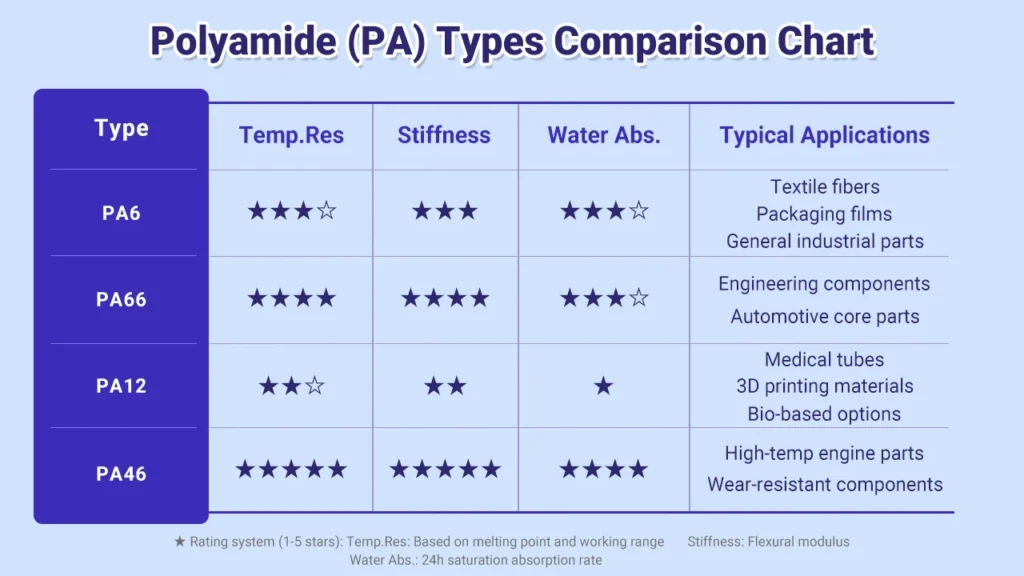

Key Polyamide Variants: PA6, PA66, PA46, and PA12

1. Polyamide 6 (PA6 / pa 6)

Characteristics: PA6 (or pa-6) is synthesized via the ring-opening polymerization of caprolactam. It offers good toughness, flexibility, and surface finish, often providing cost-effectiveness as a pa6 material.

Advantages:

Excellent impact strength and fatigue resistance.

Good surface appearance and easy colorability.

Processing temperature is lower than pa66.

what is polyamide 6? It’s the standard, tough Nylon grade.

Disadvantages:

Higher moisture absorption, which can lead to property changes in humid environments.

Melting point is lower than pa66 nylon.

Usage Scenarios: Automotive interior and exterior trim, textile fibers, and wire jacketing (pa6 plastic), often relying on pa 6 polyamide.

2. Polyamide 66 (PA66 / pa 66)

Characteristics: PA66 is formed by the polycondensation of hexamethylenediamine and adipic acid. It is the stiffest and highest-strength nylon commonly used and possesses the highest heat resistance (polyamide 66) among material pa6.6 and pa6 6 material.

Advantages:

Superior mechanical strength and rigidity.

Highest Heat Deflection Temperature (HDT) of the standard nylons.

Excellent resistance to oil and gasoline.

Disadvantages:

Higher material cost and processing temperature compared to pa6.

Similar high moisture absorption to pa6 polyamide, though slightly less prone to swelling than PA6. A key discussion is always pa6 vs pa66.

Usage Scenarios: Industrial fasteners (high-load screws), gears, bearings, and structural components requiring high stiffness and high-temperature performance (material pa66).

3. Polyamide 46 (PA46)

Characteristics: PA46 is a high-performance pa polymer known for its exceptional resistance to heat and very high crystalline melting point (approx. $295^\circ\text{C}$). It maintains high rigidity and mechanical strength under temperatures where pa6 vs pa6.6 would typically fail.

Advantages:

Excellent retention of mechanical properties at high operating temperatures.

Superior wear and friction performance under load and heat.

Disadvantages:

- Cost is significantly higher than standard nylons.

More challenging to process due to its high melting point.

Usage Scenarios: High-temperature automotive components near the engine, electrical and electronic connectors, and heavy-duty, high-speed gear applications.

4. Polyamide 12 (PA12)

Characteristics: PA12 is produced via the polymerization of laurylactam. Its key characteristic is its extremely low water absorption, excellent flexibility, and superior impact resistance.

Advantages:

Lowest moisture absorption among common polyamides (pa 12 vs pa 6), ensuring excellent dimensional stability.

Excellent flexibility and stress-cracking resistance.

Superior chemical resistance and outdoor weathering performance.

Disadvantages:

Lower mechanical strength and heat resistance compared to pa6 vs pa12 or pa6 vs pa66.

Higher cost than material pa6 and pa 66.

Usage Scenarios: Pneumatic tubing, cable sheathing, and complex, dimensionally stable parts manufactured via Selective Laser Sintering (SLS) 3D printing. The comparison pa12 vs pa6 often highlights the difference between stability and strength.

Summary and Material Selection

The question what is polyamide can be answered by looking at the best application for each grade:

For users seeking cost-effectiveness and toughness: Choose PA6 (or polyamide pa 6).

For users requiring maximum strength, rigidity, and standard high-temperature resistance: Choose PA66.

For users needing resistance to extreme high-temperature environments while maintaining performance: Choose PA46.

For users requiring low moisture absorption, high dimensional stability, and low-temperature resistance: Choose PA12.

In practice, these materials (pa material) are often modified by adding glass fibers, minerals, toughening agents, and other fillers to further enhance specific properties and meet complex design requirements. The constant debate of pa 6 vs pa66 and the emergence of material pa variants means careful selection is always required.

PA66 Screws, Nuts and Flat Washers