What is Polycarbonate (PC)?

Polycarbonate, commonly referred to as polycarbonate plastic or PC plastic, is one of the most versatile and widely used engineering thermoplastics in modern industry. Known for its exceptional impact resistance, transparency, and thermal stability, polycarbonate plays a critical role in applications ranging from electronics and automotive components to construction, medical devices, and consumer products.

Polycarbonate Chemical Structure and Formula

PC Plastic through the reaction of bisphenol A (BPA) and phosgene. The polycarbonate chemical formula is generally represented as (C15H16O₂ .CH₂O₃)n. The polycarbonate structure consists of long-chain molecules with aromatic rings linked by carbonate groups. This specific polycarbonate chemical composition is what gives the material its legendary impact resistance and optical transparency.

2. Key Physical and Thermal Properties

Understanding the polycarbonate material properties is essential for engineers deciding between pc polycarbonate and other plastics like acrylic or glass.

Density of Polycarbonate

The density of polycarbonate is one of its major advantages. The typical polycarbonate density (or pc density) is approximately 1.20 g/cm³. This makes it significantly lighter than glass, which has a density of about 2.5 g/cm³.

Temperature Ratings

The polycarbonate temperature rating is exceptional for a transparent plastic.

- Polycarbonate Glass Transition Temperature (Tg): This is roughly 147°C (297°F). At this point, the pc material begins to soften.

- Polycarbonate Temperature Limit: It can typically withstand a continuous pc material temperature of up to 125°C (257°F), making it suitable for high-heat environments like automotive headlamps.

3. Polycarbonate Synthesis and Manufacturing

The process of Polycarbon synthesis involves the polymerization of monomers to create polycarbonate resin. This resin is then sold in pellet form to manufacturers who use injection molding or extrusion to create finished goods.

When looking at what are Polycarbon plastics in their raw form, they are naturally transparent, though they can be tinted or made opaque with additives. Because it is a thermoplastic, While it is not as widely recycled as PET (soda bottles), it can be shredded and re-processed into new pc plastic products.

4. Advantages

- Impact Resistance: PC is virtually unbreakable. It has 250 times the impact strength of glass.

- Optical Clarity: It transmits light better than many types of glass, making it ideal for lenses.

- Flame Retardancy: Many Polycarbon polymer grades are self-extinguishing.

- Lightweight: As noted by the Polycarbon density, it reduces the weight of assemblies, which is critical for fuel efficiency in cars and planes.

Technical Summary Table

| Property | Value / Specification |

| Common Name | PC Plastic / Polycarbon |

| Chemical Formula | (C15H16O₂ .CH₂O₃)n |

| Density (PC Density) | 1.20 g/cm³ |

| Glass Transition Temp (Tg) | 147°C |

| Impact Strength | Extremely High (Unbreakable) |

| Light Transmission | 88–90% |

| Recycling Code | 7 (Other) |

5. Common Polycarbonate Applications

The versatility of the polycarbonate pc family allows it to be used across diverse industries:

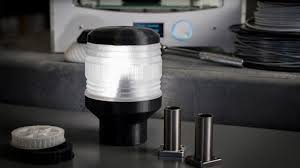

- Electronics: PC material is used for phone cases, laptop housings, and connectors due to its heat resistance and insulating properties.

- Automotive: Headlight lenses and interior trim benefit from the high polycarbonate temperature limit.

- Construction: Multi-wall polycarbonate sheets are used for greenhouses and stadium roofs.

- Medical: For medical devices, specific grades are used for surgical tools and blood oxygenators because they can be sterilized without degrading.

- Security: Bullet-resistant “glass” is actually a lamination of several pc polycarbonate layers.

6. Market and Pricing

The Polycarbon price is generally higher than that of commodity plastics like Polyethylene (PE) or Polypropylene (PP). This is due to the complex Polycarbon synthesis and the high-performance raw materials required. However, its longevity and durability often lead to a lower total cost of ownership in industrial applications.

Conclusion: Is PC Material the Right Choice?

Whether you are asking what is pc plastic for a DIY project or researching what material is pc for a high-tech engineering application, the answer is clear: polycarbonate is the premier choice for strength and clarity. Its unique polycarbonate chemical structure allows it to bridge the gap between heavy, fragile glass and soft, opaque plastics.

From its low density of Polycarbon to its high Polycarbon temperature rating, it remains a top-tier pc polymer for the 21st century.