Polyvinyl Chloride Overview

polyvinyl chloride(PVC) stands for Polyvinyl Chloride, a versatile and widely used synthetic thermoplastic polymer. It is the world’s third-most produced synthetic plastic polymer after polyethylene and polypropylene. Known for its durability, chemical resistance, and cost-effectiveness, polyvinyl chloride (colloquially called vinyl or PVC vinyl) is a material found almost everywhere, from plumbing to clothing.

The Structure and Composition of PVC Material

What is PVC made of? The base material for PVC is derived from two primary, abundant resources: salt and oil/natural gas.

The Monomer and Formula

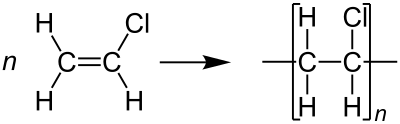

The fundamental building block for PVC is the vinyl chloride monomer (VCM).

- Preparation of VCM: Ethylene (derived from oil/gas) and Chlorine (derived from the electrolysis of saltwater) are combined to produce ethylene dichloride, which is then thermally cracked (pyrolysis) to yield the pvc monomer, vinyl chloride.

- Polymerization: Polyvinyl chloride is an addition polymer of PVC, created when thousands of vinyl chloride monomer units are linked together in a process called PVC polymerization. The resulting polymer chain has a simple backbone structure where chlorine atoms are located on alternating carbon centers. The resulting formula for polyvinyl chloride is (C₂H₃C1)n.

Main Types

The market offers several polyvinyl chloride types (PVC types), illustrating the versatility of the polyvinyl material:

- Rigid PVC (uPVC): Unplasticized PVC used for water pipes, window profiles, and electrical conduits.

- Flexible PVC: Contains plasticizers, used for electrical cables, shoe soles, and hoses.

- CPVC (Chlorinated Polyvinyl Chloride): Modified PVC with higher heat resistance, which is the key distinguishing factor in the PVC vs CPVC comparison.

- Liquid Polyvinyl Chloride (PVC Plastisol): Used for coatings, artificial leather, and waterproofing layers.

Key Characteristics

Is polyvinyl chloride a polymer? Yes, and it is a thermoplastic. Is PVC thermoplastic? Absolutely. This means that the PVC plastic material can be repeatedly heated to soften, reshaped, and cooled to become rigid again, making it highly recyclable and versatile for manufacturing.

| Property | Value (Typical Range) | Notes on PVC Characteristics |

| Density of PVC | 1.35 – 1.45 g/cm³ | Relatively high for a plastic due to the chlorine content. |

| Melting Point of PVC Pipe | 100 – 260°C (varies) | PVC melting point is generally non-fixed due to its amorphous nature and reliance on additives; decomposes at temperatures starting around 140°C. |

| Tensile Strength | 40 – 80 MPa (Rigid) | High mechanical strength, especially for rigid PVC. |

| Flame Retardancy | Excellent | The high chlorine content makes PVC self-extinguishing. |

| Chemical Resistance | Excellent | Resistant to most inorganic acids and alkalis. |

The final polyvinyl chloride properties are heavily influenced by the type of additives used:

- Rigid PVC (Unplasticized PVC or uPVC): This material is strong, stable, and used for applications requiring toughness, such as pipes and window frames. What does PVC stand for in PVC pipe? It stands for Polyvinyl Chloride.

- Flexible PVC (Plasticized PVC): When plasticized PVC is created by adding substances called plasticizers, the material becomes softer, more elastic, and rubber-like. This makes it suitable for products like medical tubing and cable insulation.

Applications and Comparison

What is PVC used for? Polyvinyl chloride applications are vast, placing it in nearly every major industry.

| Industry | Examples of PVC / What is PVC material used for |

| Construction | PVC pipes for plumbing, sewerage, and drainage; window and door frames; roofing membranes; siding; and wall coverings. |

| Electrical | Cable and wire insulation (due to its excellent electrical insulation and fire resistance). |

| Medical | IV bags, blood bags, medical tubing, and various disposable medical devices. This is where 100 polyvinyl chloride formulations are critical for biocompatibility. |

| Packaging | Rigid films for blister packaging, bottles, and food-covering sheets. |

| Consumer Goods | Flooring (often called pvc vinyl flooring), clothing (e.g., rain gear), footwear, and inflatable products. |

Comparison: PVC vs CPVC

| Property | PVC (Standard Polyvinyl Chloride) | CPVC (Chlorinated Polyvinyl Chloride) |

| Maximum Service Temperature | Approximately 60°C | Approximately 93°C |

| Cost | Low (More Economical) | High (Requires extra chlorination) |

| Use | Cold water piping, drainage, ventilation, general construction | Hot water piping, fire sprinkler systems, industrial high-pressure/corrosive media |

Advantages and Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Economics | Low Cost: Highly economical for mass production. | Limited Thermal Range: Standard PVC has a low maximum service temperature. |

| Functionality | Durable & Waterproof: Excellent longevity and immunity to moisture/corrosion. | Solvent Sensitivity: Vulnerable to certain solvents (e.g., acetone). |

| Safety | Flame Retardant: Inherently self-extinguishing due to chlorine content. | Environmental Concerns: Historical concerns regarding incineration and plasticizer use. |

Conclusion

PVC is a highly versatile plastic. From what is PVC to its structure, polymerization, performance, and applications, PVC grades,its value in the construction, electrical, medical, and consumer goods industries is immense. Understanding the pvc material meaning, properties, polyvinyl chloride types, chemical resistance, and polymerization PVC process is crucial for material selection. Whether it is Rigid PVC, Flexible PVC, or CPVC, the different polyvinyl chloride types play critical roles in the modern industrial system.

pvc Screws, Nuts and Flat Washers

PVC Cross counter sunk head screw

$1.00PVC Flat washer

$1.00PVC Hexagon head bolt

$1.00PVC Hexagon nut

$1.00PVC Hexagon socket head screw

$1.00PVC Slotted knurled screw

$1.00