The shift is driven by global trends, particularly the move towards electrification and lighter products.

1. Lightweighting

Plastic Fastener Benefits lies in weight reduction, which directly translates into improved performance and efficiency.

- Weight Reduction: Plastic fasteners typically weigh 50% to 85% less than comparable metal fasteners.

- Automotive and Aerospace: This is critical in the Electric Vehicle (EV) and aerospace industries, where every gram saved improves fuel efficiency (for traditional vehicles) or battery range (for EVs). automotive plastic fasteners used for interior components, wire harnessing, and battery pack housing

- Shipping and Handling: The lighter weight reduces overall shipping costs for the finished product.

2. Functional Superiority

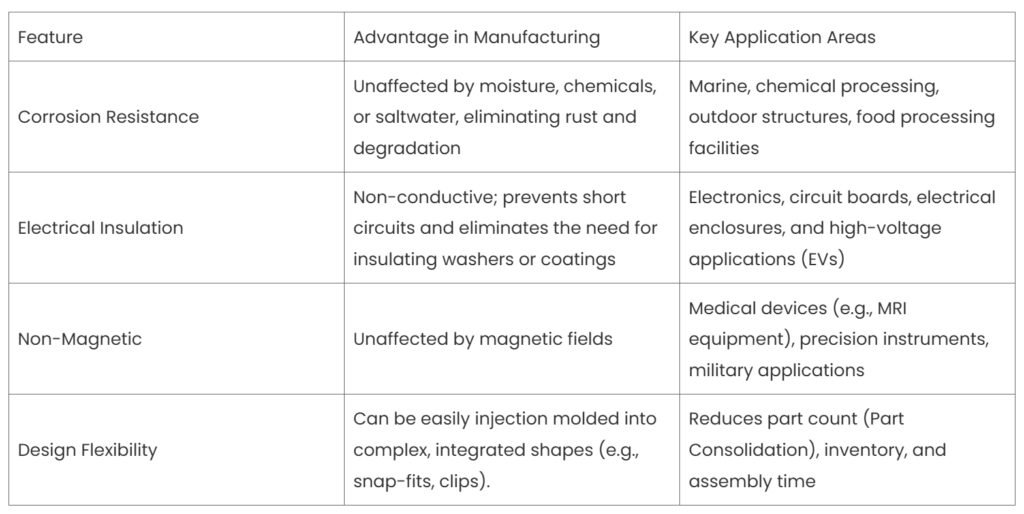

Plastic materials offer distinct chemical and electrical properties that solve complex engineering challenges, often eliminating the need for extra components.

3. Efficiency & Cost

The manufacturing process for plastic fasteners is inherently more efficient for high-volume production.

- Manufacturing Cost: Plastic resins are generally cheaper than specialty metal alloys, and high-volume injection molding is faster and less wasteful than machining or die-casting metal parts.

- Assembly Speed: Fasteners designed with features like push-in clips or snap-fits enable quicker, tool-less assembly, dramatically shortening manufacturing cycle times.

- Simplification: The ability to consolidate multiple metal parts (Plastic screw, washer, nut) into a single plastic component simplifies the Bill of Materials (BOM) and streamlines the assembly line.

4. Key Technology Trends

Materials science and Fastener Innovation provide strong support for the widespread adoption of plastic fasteners.

- Plastic Material : Modern engineering plastics like Nylon (Polyamide, PA), PEEK (for high-temp), and Polypropylene (PP) offer excellent strength-to-weight ratios and Corrosion Resistant Plastic Fasteners

- Self-Tapping Designs: Novel Thread Profile (like Hi-Lo threads or proprietary designs) are optimized specifically for plastic bosses.

5. Conclusion: Redefining the Future of Industrial Design

Plastic fastener are moving beyond simple aesthetic applications and are now trusted components in critical systems where their unique advantages—particularly lightweighting and insulation—offer transformative gains in performance and manufacturing overhead.