⚙️ Different Types and Applications of Polymer Plastic Screws

Polymer plastic screws, also known as plastic fasteners, offer unique advantages over traditional metal screws, such as high resistance to corrosion, non-conductivity, and light weight.

Classification by Material Type

| Material | Key Features | Primary Benefits |

| Nylon Screws (PA6, PA66) | High strength, high toughness, good insulation, self-lubrication, low friction coefficient, and chemical resistance. | General purpose, durable, and cost-effective. |

| Polypropylene Screws (PP) | Excellent chemical resistance (especially acids and bases), low density, light weight, and low cost. | Excellent chemical compatibility and buoyancy. |

| Polyvinyl Chloride Screws (PVC, CPVC) | Excellent corrosion resistance, especially to strong chemicals, and flame retardancy. | Superior corrosion resistance for water treatment/chemical handling. |

| Polytetrafluoroethylene Screws (PTFE/Teflon) | Known as the “King of Plastics.” Extremely low friction coefficient, excellent lubricity, non-stick properties, and wide operating temperature range -200°C to +260°C | Extreme temperature and chemical inertness. |

| Polyetheretherketone Screws (PEEK) | Near-metal strength, hardness, and creep resistance, plus extremely high heat resistance. Long-term operating temperatures exceeding mathbf250°Care possible. | High performance in harsh thermal and mechanical environments. |

| Polyoxymethylene Screws (POM/Acetal) | High stiffness and hardness (approaching metal), low coefficient of friction, and excellent self-lubrication. | High rigidity and low friction for precision moving parts. |

| Composite Screws (GFRP) | Extremely high strength-to-weight ratio (strength comparable to high-strength steel), fully insulated, and non-magnetic. | Maximum strength-to-weight ratio and EMI/RFI shielding protection. |

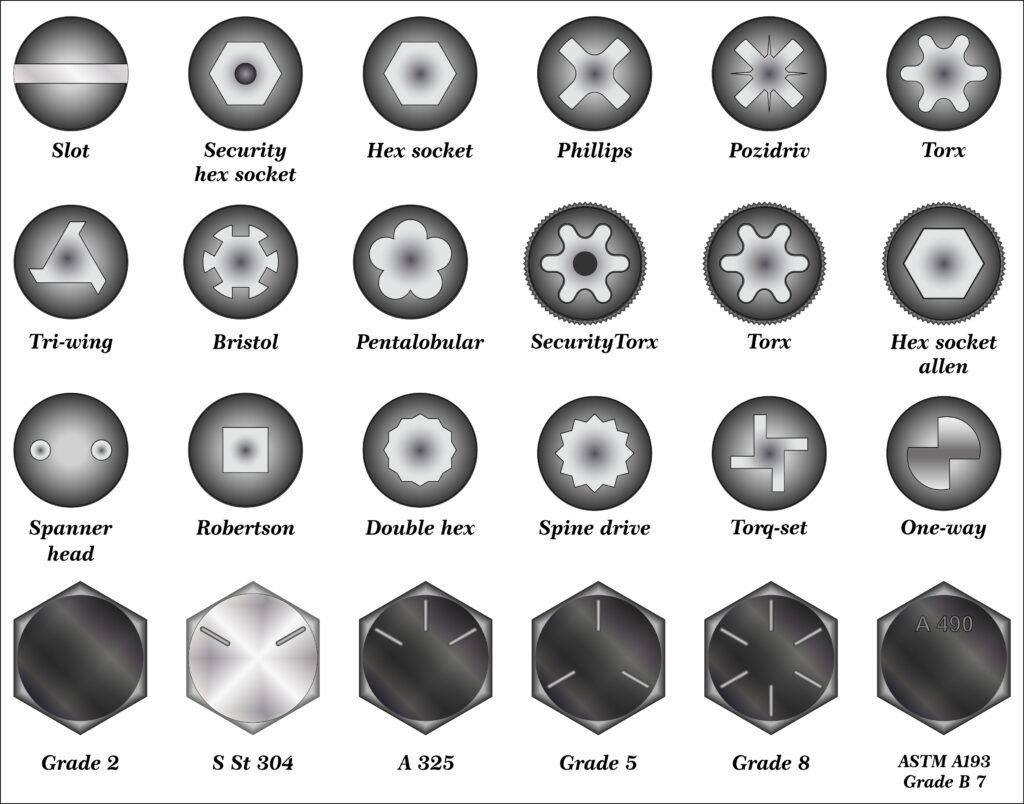

Classification by Head Type and Drive Method

This classification relates to how the screw is installed and the load it can bear.

- Head shapes: Include Pan head (rounded top), Countersunk head (flat top for flush mounting), Cylindrical head (Cap head), and Hexagonal head (external drive).

- Drive methods: Include Slotted head, Phillips head, Hexagon socket (Allen), Torx head, and Square head.

Classification by Manufacturing Process

This affects dimensional accuracy, mechanical properties, and cost.

- Injection Molded Screws: High production efficiency, low cost, and suitable for large-scale production.

- Machine-Made Screws: Cut from bar stock using a lathe or CNC machining center. Offers high dimensional accuracy, allows for customized dimensions/head shapes, and generally results in mechanical properties that surpass injection molded parts.

Key Characteristics and Advantages

Why do engineers specify plastic screws and nuts over stainless steel? The advantages are multifaceted:

- Corrosion Resistance: Unlike metal, plastic screws will never oxidize or undergo galvanic corrosion. This makes them ideal for marine environments and chemical scrubbers.

- Lightweight Performance: Polymers are roughly 1/6th the weight of steel. In the automotive industry, automotive plastic screws contribute to “lightweighting,” which is critical for extending the range of Electric Vehicles (EVs).

- Non-Conductivity: Nylon machine screws are natural insulators, eliminating the need for separate insulating washers in electrical panels.

- Aesthetics and Sealing: Plastic screw covers, plastic screw plugs, and plastic plugs for screw holes allow for a seamless finish in furniture and cabinetry. Additionally, screws with plastic covers are used in outdoor signage to prevent water ingress.

Polymer Plastic Screws Have a Wide Range of Applications

Polymer plastic screws are chosen specifically when their unique properties (insulation, chemical resistance, low density) are critical.

- Furniture Industry: Favored for their lightweight and corrosion resistance, securing parts of furniture like tables and chairs.

- Aerospace Industry: Used due to their high strength-to-weight ratio (Composite Screws, PEEK) and non-magnetic properties to fasten various aircraft components.

- Construction Industry: Used due to their ability to withstand harsh weather conditions and corrosion, fastening various building components like wall panels or roofing (often using PP or Nylon).

- Electrical Industry: Essential due to their insulating properties. They are used to secure circuit boards, wiring, and electrical system components where preventing electrical short circuits or ground paths is crucial.

Specialized Types and Functional Designs

Not all plastic screws are designed for pre-tapped holes. Many are engineered to create their own paths or provide specific aesthetic functions.

Self-Tapping and Thread Forming

For rapid assembly in softer materials, plastic self tapping screws and plastic tapping screws are used. However, for plastic-to-plastic joints, thread forming screws for plastic are superior. These screws feature a unique thread profile that displaces the polymer without cutting it, reducing the risk of material fatigue or cracking.

Structural Support and Spacing

In electronic assemblies, plastic screw spacers and plastic spacers for screws are used to maintain specific gaps between PCBs and housings, preventing electrical shorts. When a joint requires frequent disassembly, a plastic screw insert or screw insert plastic is embedded into the host material to provide a durable metal or hard-polymer thread.

Anchors and Expansion

For construction and heavy-duty mounting, the plastic expansion screw, plastic molly screws, and plastic anchor screws are essential. These utilize a sleeve that expands when the screw is driven, creating a high-friction bond with drywall or masonry.

summary

Polymer plastic screws are versatile and practical fasteners. They possess unique properties—such as high strength (PA66, PEEK, GFRP), chemical resistance (PP, PTFE), and inherent insulation—making them well-suited for applications where meta.