PEEK Slotted Pan Screw

PEEK Slotted Pan Screw are a kind of semi-crystalline special engineering plastic with superb performance; they have strong chemical resistance, excellent heat resistance, wear resistance, flame retardancy and hydrolysis resistance.

M Size: M2.5-M16

peek plastic material: Polyetheretherketone (PEEK)

Thread Type:Pan head bolts

Length Range: 15mm-200mm (Customizable)

Finish: Natural/Black/Other Colors

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Slotted Pan Screw

PEEK (Polyether Ether Ketone) Slotted Pan Head Screw is a premium plastic screw that delivers the highest mechanical, thermal, and chemical performance available in a fastener with a simple slotted drive. It is specifically designed for applications where high strength and resistance to extreme environments are needed, combined with the wide load-bearing area of the Pan Head design.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PEEK) | Polyether Ether Ketone. A semi-crystalline thermoplastic with extreme strength, high dimensional stability, and operating temperatures up to $260^\circ \text{C}$. | Ensures maximum structural integrity and environmental resistance among all polymer fasteners. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for strong clamping and pull-through resistance. |

Product Parameters

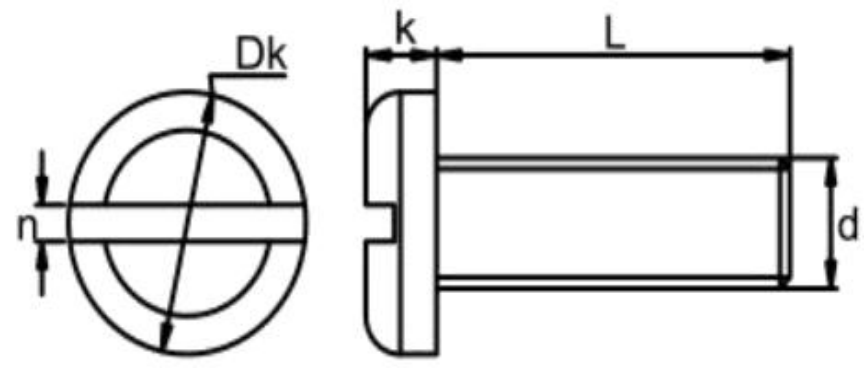

PEEK Slotted Pan Head Screws typically follow metric standards for slotted pan head screws, such as ISO 1580 or similar industry standards. The dimensions ensure standard fit while the PEEK material guarantees superior performance.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Slot Width (N) |

| M3 | 0.5 mm | 6.0 mm | 2.0 mm | 0.8 mm |

| M4 | 0.7 mm | 8.0 mm | 2.6 mm | 1.0 mm |

| M5 | 0.8 mm | 9.5 mm | 3.3 mm | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | 3.9 mm | 1.6 mm |

| M8 | 1.25 mm | 14.0 mm | 5.2 mm | 2.0 mm |

Key Features

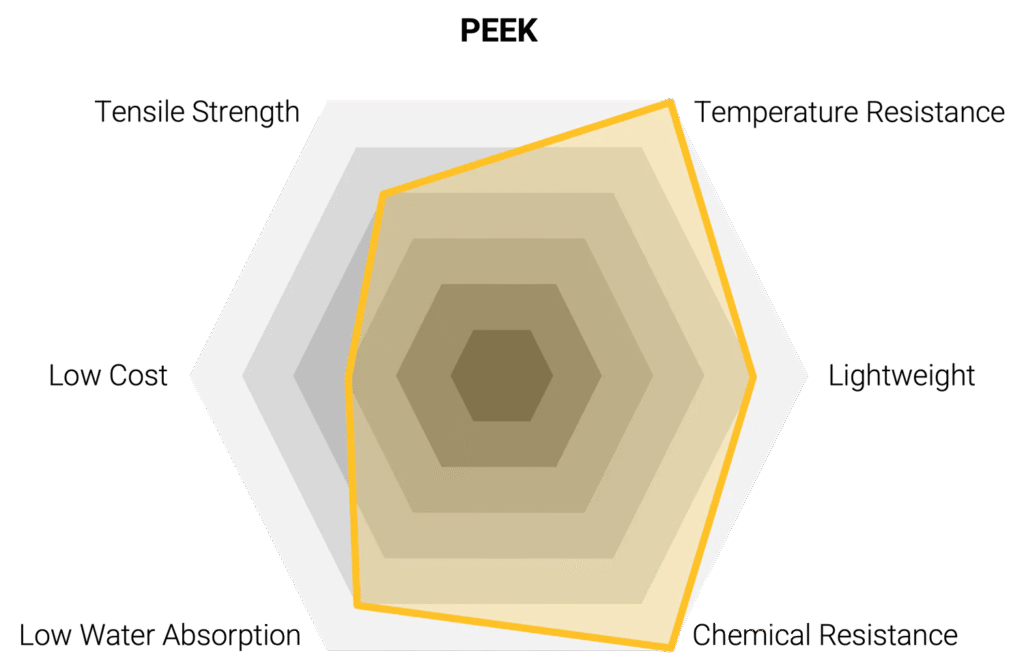

PEEK fasteners are chosen for their ability to perform in the most extreme conditions:

Extreme Thermal Stability: Maintains integrity and strength at continuous operating temperatures up to 260°C(500°C).

Superior Mechanical Strength: Offers the highest tensile strength and stiffness among all polymer fasteners, resisting creep under high load.

Chemical Inertness: Highly resistant to virtually all common solvents, acids, and bases, ideal for chemical processing.

Non-Magnetic and Non-Conductive: Essential for use in sensitive electronic, aerospace, and medical diagnostic equipment (MRI).

Corrosion Immunity: Immune to rust and galvanic corrosion, lasting longer than stainless steel in corrosive environments.

Key Polyether Ether Ketone (PEEK) Properties

Advantages and Disadvantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Unmatched Thermal and Mechanical Strength among polymers. Excellent chemical resistance. Wide clamping area (Pan Head). | Very High Cost: The most expensive fastener material among common plastics. |

| Design | Provides robust clamping force and superior resistance to pull-through due to head size. | Slotted Drive Limitation: The weakest drive type for torque; easily cammed out or stripped if over-torqued. |

| Material | Lightweight, non-contaminating, and non-corrosive. | Requires careful control of installation torque to prevent damage to the drive slot. |

Applications

The PEEK Slotted Pan Head Screw is used in critical applications across high-technology sectors:

Semiconductor Manufacturing: Securing cleanroom components and equipment where zero metallic contamination is required.

Medical Devices: Fastening non-magnetic and bio-compatible components in MRI machines and surgical tools.

High-Temperature Electronics: Securing components in ovens, hot plates, and soldering equipment operating at elevated temperatures.

Aerospace: Used in internal assemblies requiring lightweight fasteners that must withstand high heat and maintain stability.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.