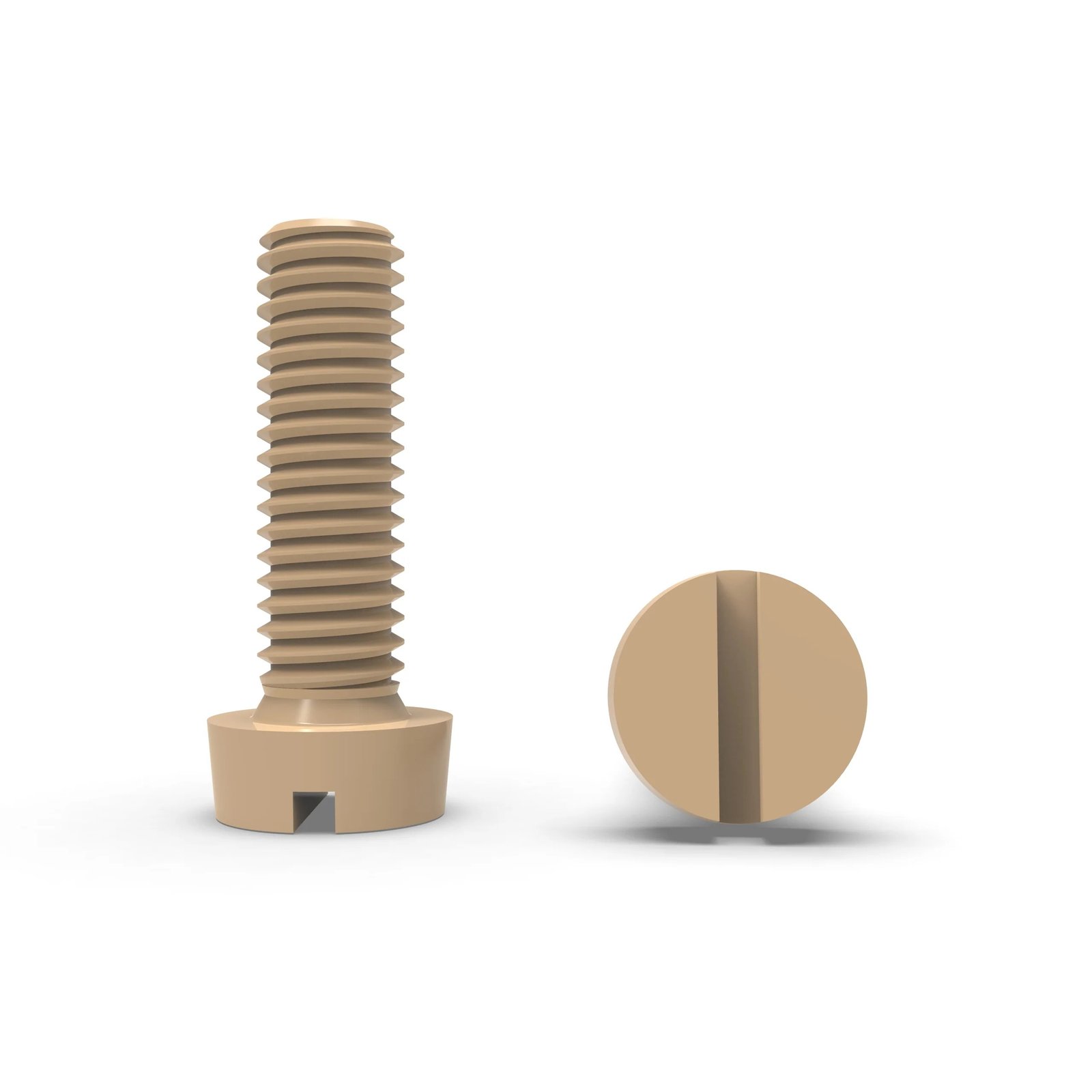

PEEK Slotted cylindrical head bolts

PEEK slotted cylindrical head bolts (internal hex head) are ultra-high performance fasteners designed for extreme and sensitive environments. They offer excellent resistance to temperature, chemical corrosion, and radiation.

M Size: M2-M10

peek plastic material: Polyetheretherketone (PEEK)

Thread Type:Cylinder head bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Slotted cylindrical head bolts Overview

PEEK Slotted Cylindrical Head Bolt (Polyether Ether Ketone, Slot Drive, Socket Head) is an ultra-high performance fastener tailored for the most extreme and sensitive environments. It combines PEEK’s industry-leading resistance to temperature, chemicals, and radiation with the practical, flush-mounting design of a cylindrical head and the simple, traditional Slotted Drive

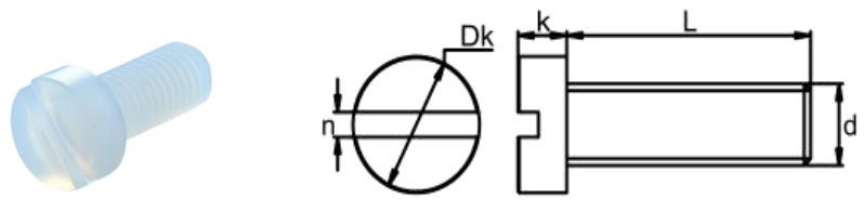

Product Parameters

These screws typically adhere to metric standards for slotted cylindrical head screws, such as ISO 1207 (Slotted Cheese Head) or similar industry standards for precision components.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Slot Width (N) |

| M3 | 0.5 mm | 5.5 mm | 2.4 mm | 0.8 mm |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm | 1.0 mm |

| M5 | 0.8 mm | 8.5 mm | 4.0 mm | 1.2 mm |

| M6 | 1.0 mm | 10.0 mm | 5.0 mm | 1.6 mm |

| M8 | 1.25 mm | 13.0 mm | 6.0 mm | 2.0 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm | 2.5 mm |

Key Features

The fastener’s properties are dictated by the premium PEEK resin:

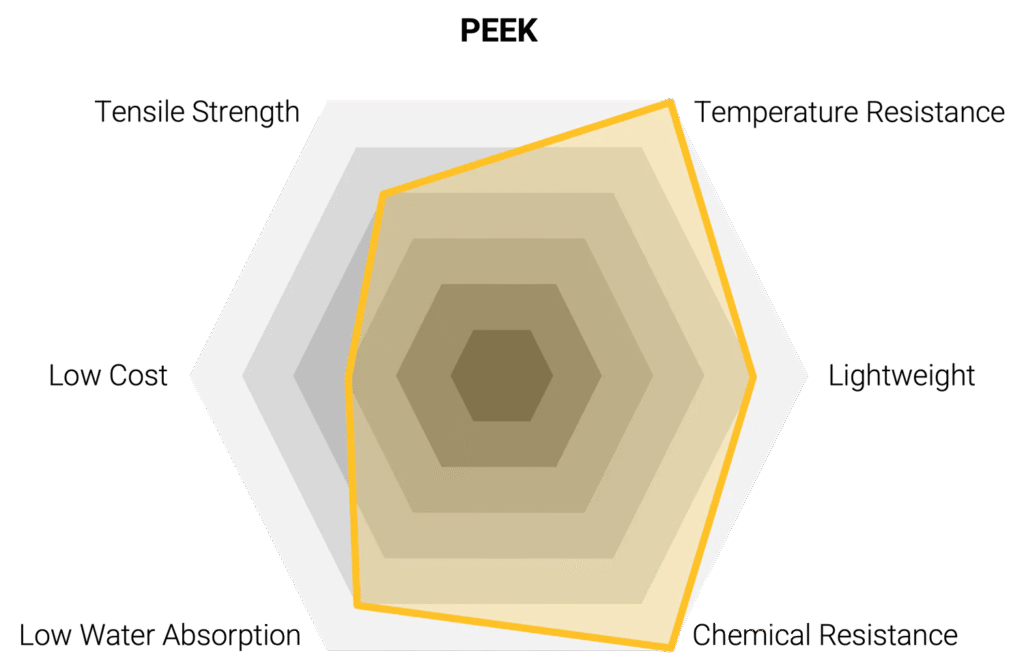

- Extreme Thermal Resistance: PEEK is stable for continuous use up to 260°C, making it the top choice for PEEK High Temperature Fasteners where standard engineering plastics like PA66 would quickly fail.

- Unrivaled Chemical Inertness: PEEK offers exceptional PEEK Chemical Resistant Bolts properties, resisting virtually all common solvents, acids, and bases, even at high temperatures and pressures (relevant to PEEK Slotted Screw Hydrolysis).

- High Mechanical Integrity and Creep Resistance: PEEK maintains high tensile strength and stiffness across its operating temperature range, offering superior PEEK Screw Creep Resistance for reliable, long-term joint preload stability.

- Non-Metallic and Non-Contaminating: It is completely non-corrosive, non-magnetic (PEEK Slotted Head Non-Magnetic), and exhibits extremely low outgassing, making it suitable for clean rooms and vacuum applications (PEEK Screw Low Outgassing).

- Cylindrical Head Design: Provides maximum clamping surface area with a compact, minimal-space-consuming head profile, suitable for close-tolerance assemblies.

Key Polyether Ether Ketone (PEEK) Properties

Applications

The PEEK Slotted Cylindrical Head Bolt is reserved for environments where its extreme capabilities justify its high cost:

- Oil & Gas and Chemical Processing: Used for internal components, sensors, and flange connections exposed to superheated steam, aggressive chemicals, and high pressures.

- Medical and Scientific Equipment: Utilized as PEEK Medical Grade Fasteners in sterilization equipment (autoclaves) and analytical instruments where non-magnetic properties, chemical resistance, and high-temperature stability are critical.

- Aerospace and Defense: Applied in sensor mounts, structural isolation, and electrical components where lightweighting and extreme thermal resistance are mandatory.

- Semiconductor Manufacturing: Employed in wafer processing and vacuum chambers due to its high purity, low outgassing, and resistance to plasma.

Advantages&Disadvantages

✅ Advantages (Pros)

- Extreme Performance: Unmatched resistance to heat, chemicals, and radiation among polymers.

- Structural Integrity: Maintains high strength and excellent Creep Resistance up to $260^\circ \text{C}$.

- Non-Contaminating: High purity, non-magnetic, and low outgassing for clean/vacuum environments.

- Corrosion Proof: Offers absolute immunity to virtually all corrosive agents.

- Simple Servicing: The Slotted Drive allows for straightforward PEEK Slot Screw Ease of Removal with basic tools.

❌ Disadvantages (Cons)

- Prohibitive Cost: PEEK is one of the most expensive raw materials, significantly limiting applications (see PEEK Screw Price Suppliers).

- High Cam-Out Risk: The extremely rigid PEEK material, combined with the inherently low-efficiency Slotted Drive, makes it highly susceptible to PEEK Slotted Screw Cam-Out and damage to the head recess during installation.

- Installation Difficulty: The material’s rigidity requires precise threading and torque control to prevent stripping the mating part or damaging the bolt.

- Tool Wear: The hardness of PEEK can increase wear on standard assembly tools.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.