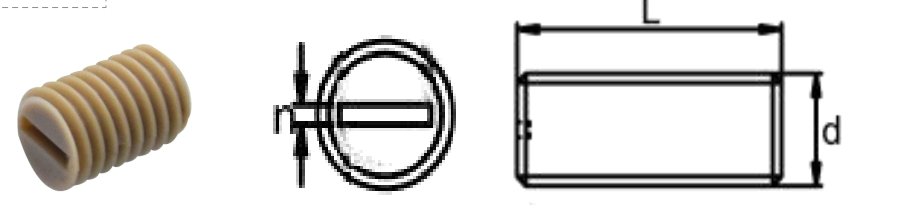

PEEK Slotted flat end set screw

PEEK Slotted flat end set screw are a kind of semi-crystalline special engineering plastic with superb performance; they have strong chemical resistance, excellent heat resistance, wear resistance, flame retardancy and hydrolysis resistance.

M Size: M3-M6

peek plastic material: Polyetheretherketone (PEEK)

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Slotted flat end set screw Overview

PEEK Slotted Flat End Set Screws are high-performance fastening components manufactured from PEEK (Polyether Ether Ketone)—a premium engineering thermoplastic known for outstanding chemical resistance, exceptional heat stability, and mechanical strength comparable to lightweight metals.

Key Features

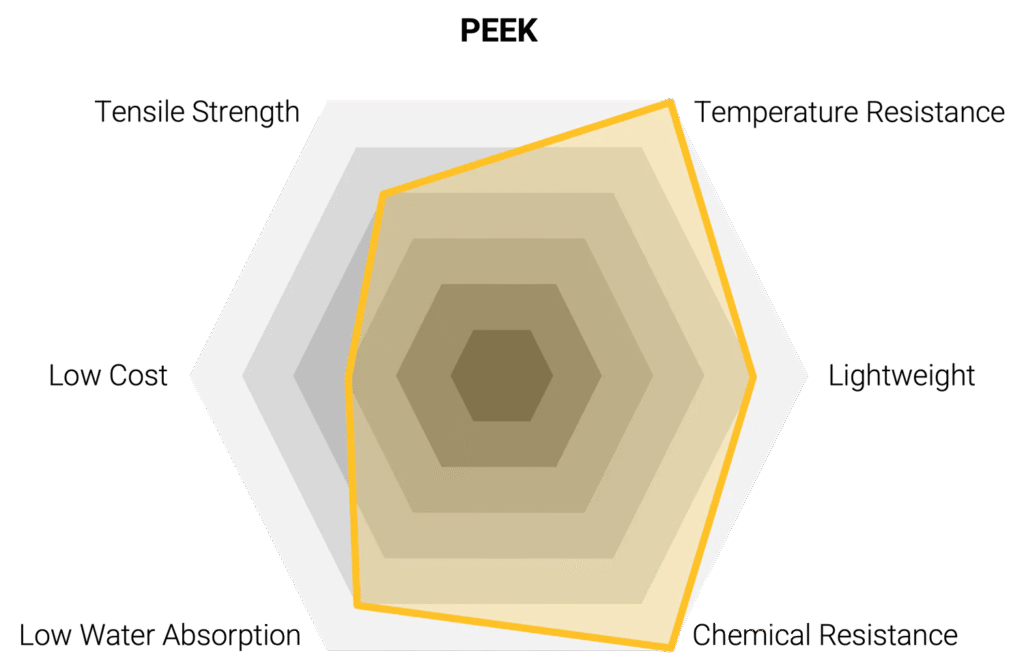

PEEK set screws are chosen over metal and other plastics due to their superior performance profile in demanding environments:

Extreme Thermal Resistance: PEEK maintains its mechanical properties and structural integrity up to continuous operating temperatures of 260°C(500°C).

High Strength-to-Weight Ratio: Offers exceptional stiffness and tensile strength, making it the strongest available plastic screw while remaining non-magnetic and significantly lighter than metal.

Chemical Inertness: Highly resistant to virtually all common industrial chemicals, solvents, and corrosive agents.

Non-Conductive: Excellent electrical insulator, crucial for sensitive electronic and high-voltage applications.

Zero Contamination: Non-leaching and high-purity, essential for use in medical, pharmaceutical, and ultra-pure water systems.

Key Polyether Ether Ketone (PEEK) Properties

Applications

PEEK Slotted Flat End Set Screws are commonly found in:

High-Temperature Environments: Securing components in ovens, soldering equipment, or engine compartments where other plastics melt.

Sensitive Electronics: Used as internal stops or adjustable limiters where non-conductivity is required.

Medical and Scientific Equipment: Fastening adjustment mechanisms in analytical instruments where non-magnetic properties and chemical resistance are mandatory.

Semiconductor Manufacturing: Securing fixtures or components in wet-process tools exposed to aggressive chemicals and heat.

Advantages vs Disadvantage

✓ Withstands extreme heat

Continuous working temperature up to 260°C.

✓ Superior chemical resistance

More resistant than aluminum or stainless steel.

✓ Lightweight and corrosion-free

No rust or galvanic corrosion.

✓ Electrically insulating

Suitable for high-voltage applications.

✓ High mechanical strength

Comparable to certain metals while being lighter.

✓ Cleanroom compatible

Produces minimal particulates.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.