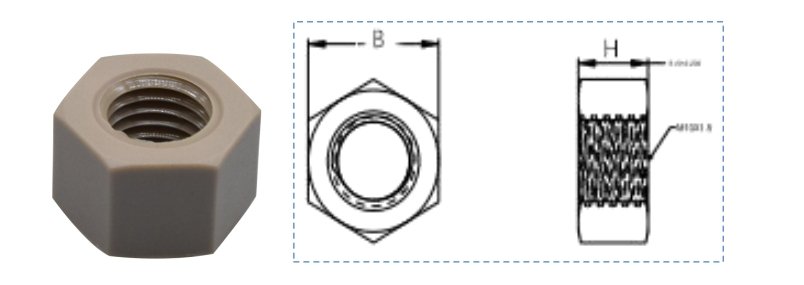

PEEK Hexagonal nut

PEEK hexagon nut (or PEEK hex nut) is a six-sided nut made from Polyether Ether Ketone (PEEK),The Ultra-High-Performance Polymer Fastener.

M Size: M2-M20

peek plastic material: Polyetheretherketone (PEEK)

productType:Nuts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Hexagonal nut Overview

PEEK hexagon nut (or PEEK hex nut) is a six-sided nut made from Polyether Ether Ketone (PEEK), PEEK hex nuts deliver a blend of high chemical resistance, thermal stability, lightweight structure, and strong mechanical performance.

Product Parameters

PEEK Hexagonal Nuts typically follow established metric standards for regular hexagon nuts, such as ISO 4032, ensuring compatibility with standard bolts, threaded rods, and tools.

| Nominal Size (Bolt d) | Thread Pitch (P) | Across Flats (s) | Nut Height (m) |

| M3 | 0.5 mm | 5.5 mm | 2.4 mm |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm |

| M5 | 0.8 mm | 8.0 mm | 4.7 mm |

| M6 | 1.0 mm | 10.0 mm | 5.2 mm |

| M8 | 1.25 mm | 13.0 mm | 6.4 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 10.0 mm |

| M16 | 2.0 mm | 24.0 mm | 13.0 mm |

Key Features

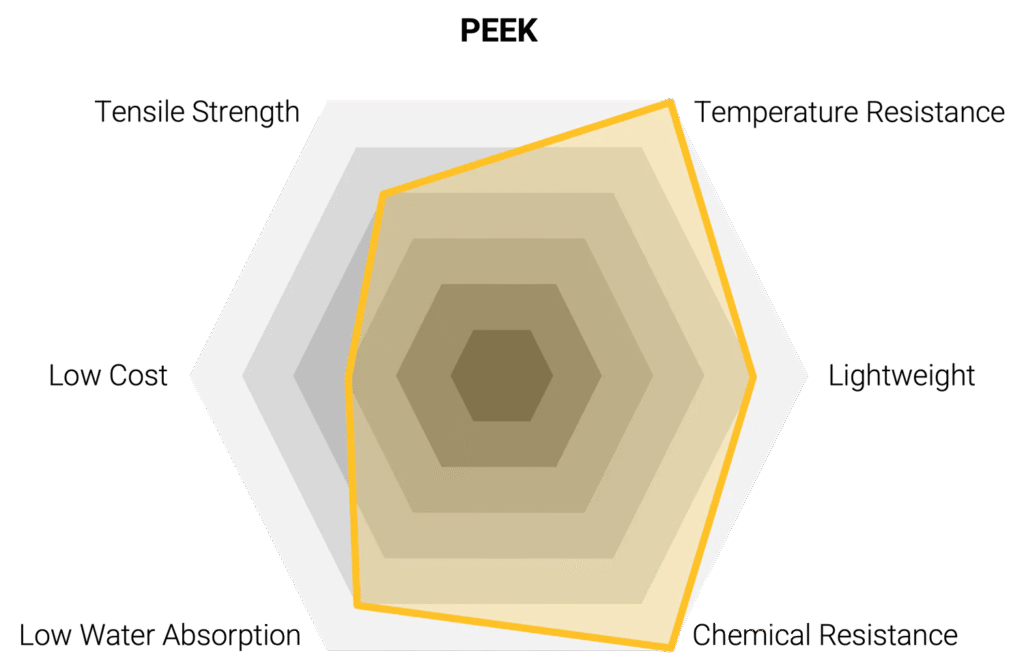

The essential features of the PEEK hex nut are directly derived from the Polymer Ether Ether Ketone structure, positioning it at the top tier of plastic hex nut options:

Exceptional Thermal Resistance: PEEK has a high continuous service temperature (up to 260°C), allowing it to perform where most plastic screws or nylon hex nut variants would melt or degrade.

Superior Mechanical Strength: It possesses high tensile and flexural strength, offering the best performance among all unreinforced thermoplastics, rivaling some lightweight metals. The hex nut diameter and hex nut height are manufactured to precise standards.

Chemical Inertness: PEEK is resistant to a massive range of organic and inorganic solvents, acids, and bases—a primary advantage over even stainless steel hex nuts in harsh chemical environments.

Radiation and Hydrolysis Resistance: Exceptional resistance to high-energy radiation and hot water/steam (autoclave sterilization), which is critical for medical and nuclear applications.

Electrical Insulation: It is inherently non-conductive, providing electrical and thermal isolation in any bolt hex nut assembly.

Key Polyether Ether Ketone (PEEK) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Performance | Extreme Temperature Resistance: Operates up to 260°C. Universal Chemical Resistance: Unmatched by other polymers. Superior strength among all plastic hex nut materials. | Cost: PEEK is one of the most expensive polymers available. The cost per unit is significantly higher than hex bolt nut materials like stainless steel or brass. |

| Functionality | Excellent wear properties, making it suitable for assemblies requiring repeated adjustment. Can be used in conjunction with metal hex head bolt for specific hybrid applications. | Torque Limitations: Although strong, it cannot withstand the same installation torque as high-grade steel hex nuts, necessitating the use of specific low-torque settings with a sensitive nut driver hex. |

| Procurement | Available in standard dimensions (hex nut sizes, metric hex nuts) simplifying replacement and design integration. | Vibration Resistance: Like all polymers, PEEK can be susceptible to creep under high stress and may require specific design elements to function as a hex lock nuts or a true nylock hex nut alternative. |

| Comparison | Superior to Nylon: Addresses the thermal and chemical weaknesses of the common nylon hex nut. Solves the lock nut vs hex nut dilemma in chemical environments where metal is unsuitable. | Availability: Specialized material requiring sourcing from specific, high-end polymer fastener suppliers, unlike commodity hex nut products. |

Applications

The PEEK Hexagonal Nut is used when no other polymer or metal can meet the demanding requirements simultaneously.

Aerospace and Automotive: Used in engine components, sensor mountings, and lightweighting initiatives where high heat, chemical exposure, and weight reduction are mandatory.

Medical and Pharmaceutical: Ideal for equipment requiring repeated autoclave sterilization (steam and heat) due to its resistance to hydrolysis.

Chemical Processing: Employed in pumps, valves, and fluid handling systems where fasteners are constantly exposed to highly corrosive media at elevated temperatures. This is often where a standard metal hex head nut would fail.

Semiconductor Manufacturing: Valued for its purity and low outgassing properties, preventing contamination in vacuum chambers and clean rooms.

High-Performance Electronics: Used as an insulating fastener where high strength is required, often replacing weaker plastic hex nut caps or conventional insulators.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.