PEEK Flat Washers

PEEK Flat Washers are ultra-high-end bearings and spacers with unparalleled heat resistance, chemical resistance, and mechanical strength.

M Size: M2-M20

peek plastic material: Polyetheretherketone (PEEK)

product Type: Washers

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Flat Washers Overview

PEEK flat washer is a high-performance, flat, ring-shaped fastener accessory made from polyether ether ketone (PEEK),washers offer an unparalleled combination of extreme thermal, chemical, and mechanical resistance, distinguishing them dramatically from standard materials like flat washer nylon or even stainless flat washer options.

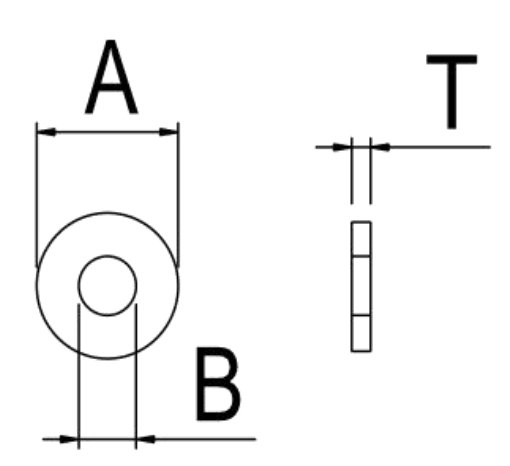

Product Parameters

PEEK Flat Washers generally adhere to established metric standards for plain washers, such as ISO 7089 (Non-chamfered) or ISO 7090 (Chamfered), with dimensions defined by the inner diameter (ID), outer diameter (OD), and thickness (T).

| Nominal Size (Bolt d) | Inner Diameter (ID) | Outer Diameter (OD) | Thickness (T) |

| M3 | 3.2 mm | 7.0 mm | 0.5 mm |

| M4 | 4.3 mm | 9.0 mm | 0.8 mm |

| M5 | 5.3 mm | 10.0 mm | 1.0 mm |

| M6 | 6.4 mm | 12.0 mm | 1.6 mm |

| M8 | 8.4 mm | 16.0 mm | 1.6 mm |

| M10 | 10.5 mm | 20.0 mm | 2.0 mm |

| M12 | 13.0 mm | 24.0 mm | 2.5 mm |

| M16 | 17.0 mm | 30.0 mm | 3.0 mm |

Key Features

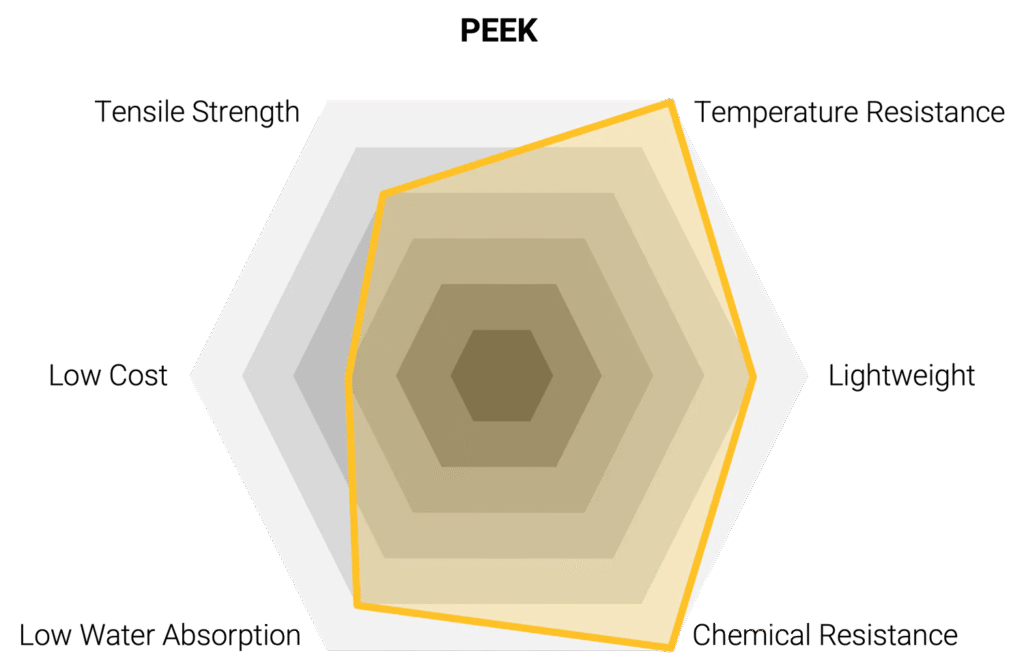

PEEK’s inherent material properties define its elite performance characteristics, positioning it at the apex of non-metallic washer options:

Extreme Thermal Resistance: PEEK has a continuous service temperature of up to 260°C(over 500°C), vastly exceeding that of any standard plastic or flat washer nylon.

Exceptional Chemical Inertness: It exhibits near-universal resistance to virtually all common solvents, acids, and bases, often providing better chemical resistance than even the best stainless flat washer alloys.

Superior Mechanical Strength: PEEK washers maintain high mechanical integrity, stiffness, and dimensional stability, with excellent resistance to creep and wear, even under high stress and elevated temperatures.

Excellent Hydrolysis Resistance: It is highly resistant to hot water and steam, making it ideal for repeated sterilization (autoclave) processes.

Low Friction and Wear: Its material properties lend themselves well to dynamic load applications, offering a low coefficient of friction.

Non-Conductivity: Provides reliable electrical isolation, eliminating the potential for galvanic corrosion.

Key Polyether Ether Ketone (PEEK) Properties

Applications

PEEK Flat Washers are employed in critical assemblies across several high-stakes industries where failure due to heat or chemical attack is unacceptable.

Aerospace and Defense: Used in sensor mounting, thermal break applications, and lightweight structural assemblies due to low density and high performance.

Medical and Pharmaceutical: Essential in sterilization equipment, processing tanks, and surgical tools where components must survive repeated exposure to high-pressure steam and harsh cleaners.

Chemical Processing: Used to protect sensitive equipment and prevent galvanic corrosion between dissimilar metal fasteners and surfaces in pumps, valves, and piping exposed to aggressive media.

High-Temperature Machinery: Employed in specialized engines, furnaces, and semiconductor manufacturing where sustained high heat is present.

Electronics (High-End): Used as protective caps or isolation layers in critical electronic devices to manage heat dissipation and provide reliable dielectric separation.

Advantages

High temperature stability – works where metal washers may deform or degrade.

Excellent chemical resistance – ideal for aggressive environments.

Electrical insulation – avoids conductivity issues.

High mechanical strength – resists fatigue and creep under load.

Low maintenance – long service life reduces downtime.

Precision manufacturing – tight tolerance enables consistent performance.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.