PTFE Hexagon head bolt

PTFE Hexagon head bolt has excellent chemical stability, corrosion resistance, heat resistance and cold resistance, flame retardant grade UL94 V-0, and can be used for a long time at -190~260℃.

M Size: M3-M10

peek plastic material: Polytetra fluoroe thylene(PTFE )

product Type: Hexagon head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PTFE Hexagon head bolt Overview

PTFE (Polytetrafluoroethylene, or Teflon) Hexagon Head Bolt is a premium, high-performance fluoropolymer fastener renowned for its exceptional chemical inertness, wide temperature stability, and high purity. The Hexagon Head design allows for external wrench tightening, enabling the most secure and controlled clamping force achievable with this soft material.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PTFE) | Polytetrafluoroethylene. A high-performance fluoropolymer with the lowest coefficient of friction and highest chemical inertness of all plastics. | Provides a fastener that is virtually impervious to all industrial chemicals and functions across an extremely wide temperature range. |

| Head Style (Hex Head) | Standard six-sided external head. | Designed for maximum wrench grip, allowing for the most controlled and secure tightening possible with this soft material. |

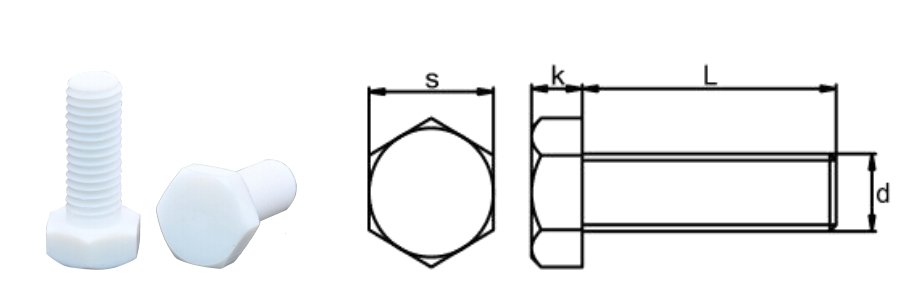

Product Parameters

PTFE Hexagon Head Bolts typically follow established metric standards for hexagon head bolts, such as ISO 4014 (partially threaded) or ISO 4017 (fully threaded).

| Nominal Diameter (d) | Thread Pitch (P) | Across Flats (s) | Head Height (k) |

| M5 | 0.8 mm | 8.0 mm | 3.5 mm |

| M6 | 1.0 mm | 10.0 mm | 4.0 mm |

| M8 | 1.25 mm | 13.0 mm | 5.3 mm |

| M10 | 1.5 mm | 16.0 mm | 6.4 mm |

| M12 | 1.75 mm | 18.0 mm | 7.5 mm |

| M16 | 2.0 mm | 24.0 mm | 10.0 mm |

Key Features

PTFE fasteners are defined by their extreme chemical and thermal performance:

Universal Chemical Inertness: Unaffected by virtually all industrial chemicals, solvents, and corrosive agents, including hydrofluoric acid and strong caustics.

Extreme Temperature Range: Operates reliably from approximately 200°C to 260°C, suitable for both cryogenic and high-heat systems.

High Purity: Does not leach contaminants, vital for pharmaceutical and ultra-pure processes.

Corrosion Immunity: Will not rust or cause galvanic corrosion, making it ideal for joining dissimilar materials (metals).

Non-Conductive: Excellent dielectric strength, offering superior electrical insulation.

Advantages and Disadvantages and Usage Scenarios

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Highest chemical and temperature resistance of all plastics. Excellent non-stick and non-contaminating properties. | Low Mechanical Strength: Very soft with high cold flow (creep), leading to thread stripping and joint relaxation over time. | Chemical Reactors/Piping: Structural fastening in flanges and vessels exposed to highly aggressive acids and solvents. |

| Design | Hex Head allows for the most controlled tightening (using a torque wrench) for this soft material. | Torque Restriction: Must be installed with very low, controlled torque; requires periodic re-tightening due to creep. | Cryogenic/High-Heat Equipment: Structural fastening in systems operating at temperature extremes (e.g., 150°C or 250°C). |

| Environmental | Non-corrosive, non-magnetic, and UV resistant. Ideal for ultra-high purity systems. | High Cost: The most expensive common polymer fastener material. | Pharmaceutical/Semiconductor: Non-contaminating assemblies where steam sterilization or harsh cleaning agents are used. |

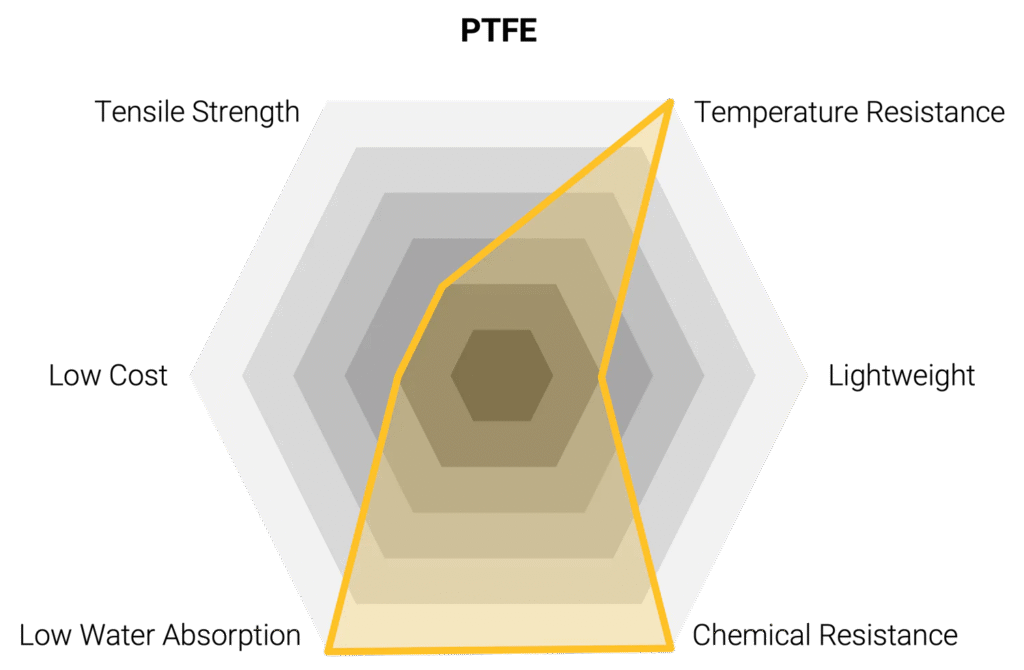

Key Polytetrafluoroethylene (PTFE) Properties

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.