PFA Hexagon head bolt

PFA Hexagon head bolt is known as the “King of Plastics”. It is corrosion-resistant and electrically insulating. It is not affected by temperature and can be used for a long time at -80~260℃.

M Size: M4-M10

peek plastic material:Polyvinylidenefluoride(PFA)

product type: Hexagon head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PFA Hexagon head bolt Overview

PFA (Perfluoroalkoxy Alkane) Hexagon Head Bolt is a critical, ultra-high-performance plastic bolt utilized in industrial applications demanding maximum chemical resistance and extreme thermal stability. Featuring the traditional hexagonal head, which is externally driven with a wrench, this bolt provides the highest chemical and heat immunity available in a structurally stable polymer fastener.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PFA) | Perfluoroalkoxy Alkane. A high-purity fluoropolymer with extreme chemical and thermal stability. | Ensures the joint is completely immune to corrosion and chemical attack across a wide temperature range. |

| Design (Hexagon Head) | Standard six-sided head, designed for high torque transfer using wrenches (spanners). | Allows for maximum tightening force achievable with PFA, providing secure, reliable assembly. |

| Application | Through-hole fastening (requires a corresponding PFA nut and washer) or threading into a tapped hole. | Ideal for demanding fluid handling and chemical equipment where metal must be avoided. |

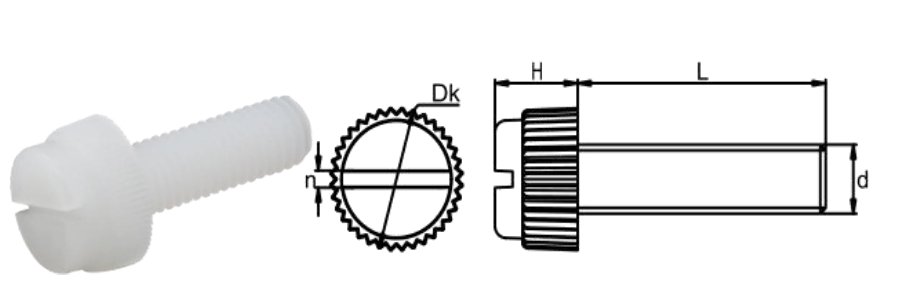

Product Parameters

PFA Hexagon Head Bolts adhere to established international standards, typically ISO 4014 (partially threaded) or ISO 4017 (fully threaded), ensuring compatibility with standard metric tools and components.

| Nominal Diameter (d) | Thread Pitch (P) | Across Flats (s) | Head Height (k) |

| M4 | 0.7 mm | 7.0 mm | 2.8 mm |

| M6 | 1.0 mm | 10.0 mm | 4.0 mm |

| M8 | 1.25 mm | 13.0 mm | 5.3 mm |

| M10 | 1.5 mm | 16.0 mm | 6.4 mm |

| M12 | 1.75 mm | 18.0 mm | 7.5 mm |

| M16 | 2.0 mm | 24.0 mm | 10.0 mm |

Key Features

PFA Hexagon Head Bolts are selected for their superior performance in critical environmental stress conditions:

Extreme Chemical Resistance: Unaffected by virtually all industrial chemicals, solvents, and concentrated acids up to its maximum service temperature.

Thermal Stability: Maintains integrity and chemical resistance from cryogenic lows up to approximately $260^\circ \text{C}$ ($500^\circ \text{F}$).

Corrosion & Galvanic Immunity: Eliminates the risk of rust, corrosion, or galvanic interaction when used near metal components.

Ultra-High Purity: Non-leaching and non-contaminating, essential for UPW and pharmaceutical systems.

Non-Conductive & Non-Magnetic: Provides crucial electrical isolation for sensitive equipment.

Advantages and Disadvantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Unmatched Chemical and Thermal Resistance. Excellent seal maintenance in corrosive media. Zero contamination. | Low Mechanical Strength: Cannot withstand the high tensile/clamping forces of structural metal bolts. |

| Material | Non-corrosive, Non-magnetic, Excellent Insulator. | Cold Flow (Creep): PFA is prone to deforming permanently under sustained, high compressive pressure, potentially leading to joint loosening. |

| Cost | Provides the highest level of purity and resistance available in a fastener. | Very High Cost due to specialized material and complex manufacturing processes. |

Applications

PFA Hexagon Head Bolts are essential in the most demanding, mission-critical environments:

Semiconductor Manufacturing: Used for securing high-purity piping, fixtures, and assemblies in wet etching and chemical delivery systems to prevent metallic ion contamination.

Chemical Processing: Fastening flanges, valves, and pump components exposed to aggressive, hot processing fluids and concentrated chemicals.

High-Temperature Equipment: Securing components in ovens, sterilizers, and processing equipment operating at elevated temperatures.

Laboratory & Analytical Equipment: Used in reactors and instrumentation requiring total chemical inertness and non-magnetic properties.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.