PA66 Hexagon head bolt

PA66 Hexagon head bolt are hexagonal fasteners injection molded from PA66 (polyamide 66, or Nylon 66), a high-performance engineering thermoplastic

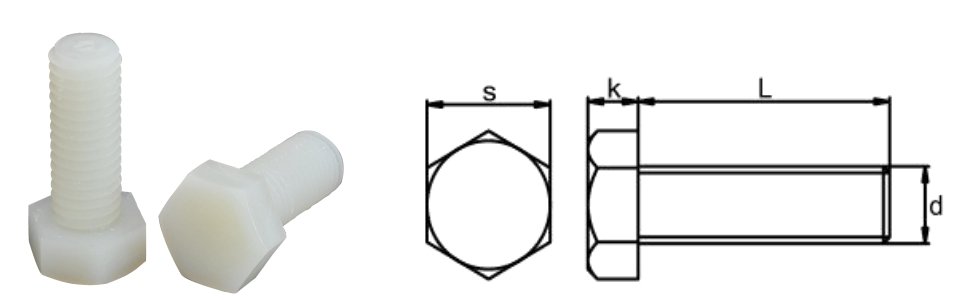

M Size: M3-M8

peek plastic material: Polyamide66(PA66)

product type: Hex Bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 Hexagon head bolt Overview

PA66 hex head bolts are hexagonal fasteners injection molded from PA66 (polyamide 66 or Nylon 66), a high-performance engineering thermoplastic. PA66 material is produced through the condensation polymerization of hexamethylenediamine and adipic acid, and is known for its high crystallinity. It belongs to the category of Nylon Screws and Plastic Screws.

Key Features

- PA66 Electrical Insulation Bolt :feature makes it an ideal choice for electronic and electrical equipment.

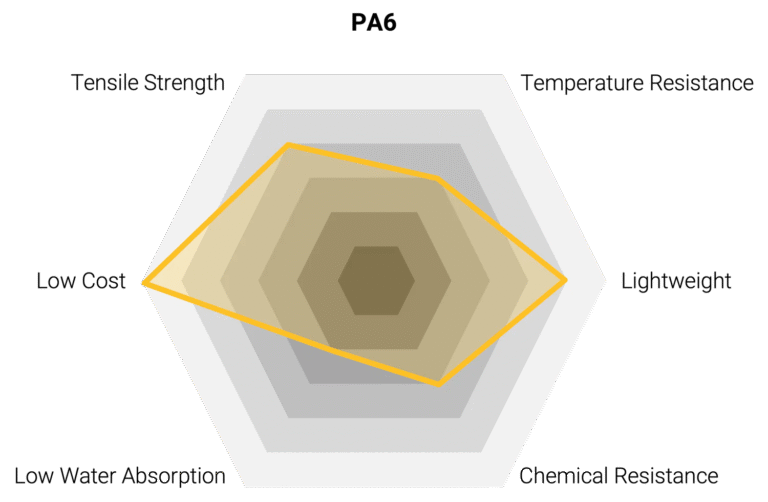

- Chemical Corrosion Resistance (PA66 Corrosion Resistance): PA66 is capable of withstanding fuels, oils, and weak alkaline solutions. This means it never rusts, making it highly suitable for marine and chemical environments.

- Mechanical Properties: PA66 possesses good strength and stiffness (PA66), and its low density provides a huge lightweight advantage (PA66 Bolt Lightweight Advantage). Its weight is only about 1/7th that of a metal bolt of the same specification, making it the main driver for achieving PA66 (PA66 Bolt Replacement Metal)

- Temperature Resistance: PA66 material also features good vibration damping (PA66 Vibration Damping) and a relatively high melting point (approx. 265°C, relevant to searches for PA66 High Temperature Bolt).

From a business perspective, the mass injection molding production leads to PA66 Bolt Cost Effectiveness, which is another major advantage.

Key Polyamide Nylon (PA6) Properties

Pros and Cons Analysis

- The advantages of PA66 bolts include: safety through insulation, complete corrosion resistance, significant lightweight effect, good vibration and noise damping characteristics, and overall cost effectiveness.

Limitations of PA66 Bolts:

- Lower Load-Bearing Capacity than Metal: Concerns over structural reliability are reflected in searches for PA66 (PA66 Bolt Strength Limitations). This necessitates strict control of torque during assembly (Nylon Bolt Torque Specs), as overtightening can easily cause the bolt head to strip or break.

- Moisture Absorption: PA66 exhibits a certain degree of moisture absorption (PA66 Water Absorption), which causes slight changes in its dimensions and mechanical properties after moisture uptake.

- Heat Resistance: The heat resistance is decent but still lower than that of specialty plastics such as PEEK.

Applications

- Electronics and Electrical Industry: It is widely used in applications requiring insulation, such as printed circuit board (PCB) isolation and power supply housing fastening

- Automotive Industry: It is a key component in achieving automotive lightweighting, used for interior components, wiring harness fixation, and non-structural load fastening for Electric Vehicle (EV) battery packs (PA66 Automotive Fasteners).

- Non-Magnetic and Chemical Resistance: It also plays an important role in medical device fasteners and chemical equipment.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.