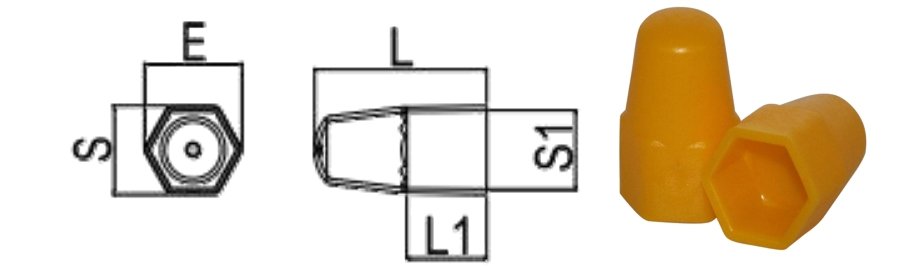

Hex Head Protection Caps

Hex Head Protection Caps, also known as hexagonal bolt caps, hexagonal caps, or hexagonal nut protectors, primarily serve to ensure safety, aesthetics, and durability.

M Size: M8-M30

peek plastic material: PE

product type: Protective caps

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

Overview of Hex Raised Protective Cap

Hex Head Protection Caps are specialized fastener covers designed to shield hex bolts and nuts from damage, corrosion, and wear while providing a clean, finished appearance。

Common types include:

Hex Cover Caps – Snap-on or screw-on caps designed to fit over standard hex bolts.

Hex Bolt Caps – Protective caps specifically for hex bolts to prevent damage and rust.

Hex Nut Protectors – Covers for hex nuts to improve aesthetics and extend service life.

Internal Hex Socket Protective Cap – Features a recessed internal hex, allowing Allen keys or hex wrenches to adjust the bolt without removing the cap.

Key Features

Hex bolt caps and hex nut protectors are deployed in any environment where safety, finished appearance, or fastener longevity is prioritized.

Playground and Recreational Equipment: A crucial application where hex nut protectors cover exposed threads, eliminating sharp edges and enhancing child safety.

Automotive and Vehicle Assembly: Used to cover visible fasteners on trim, chassis, and engine bay components to improve aesthetics and protect against road salt and moisture.

Fencing and Outdoor Structures: Essential for hex cover caps to protect the fasteners used in metal fencing, gates, and signposts from rust and environmental degradation.

Furniture and Interior Design: Used on visible fixtures and shelving to provide a clean, professional, and finished look, acting as a decorative element.

Industrial Machinery: Used as protective caps to keep dirt, debris, and paint away from the top of the fastener, ensuring that a socket or wrench can access the head when maintenance is required.

Applications

Industrial Equipment: Protects machinery bolts from corrosion and debris.

Automotive: Covers exposed hex bolts and nuts on vehicles, engines, and frames.

Furniture Assembly: Decorative and protective caps for hex screws and bolts.

Electronics: Insulates and protects fasteners in electrical and electronic assemblies.

Outdoor & Marine Environments: Stainless steel and UV-resistant plastic caps prevent corrosion from moisture and saltwater.

DIY & Home Improvement: Enhances both safety and appearance of household projects.

Advantages and Disadvantages

Advantages

Enhanced Safety: Reduces risk of injury from sharp or protruding bolt heads.

Corrosion Resistance: Extends service life of fasteners in harsh environments.

Versatility: Compatible with bolts and nuts of various sizes and materials.

Easy Maintenance: Internal hex socket designs allow bolt adjustment without removing the cap.

Aesthetic Appeal: Improves the look of exposed fasteners in furniture, machinery, and vehicles.

Disadvantages

Cost: Metal protective caps (stainless steel, brass) are more expensive than plastic alternatives.

Size Limitations: Must match the bolt or nut size precisely.

Material Strength: Plastic or nylon caps may deform under high torque or heavy loads.

Installation Fit: Press-fit designs may require careful alignment to avoid loosening.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.