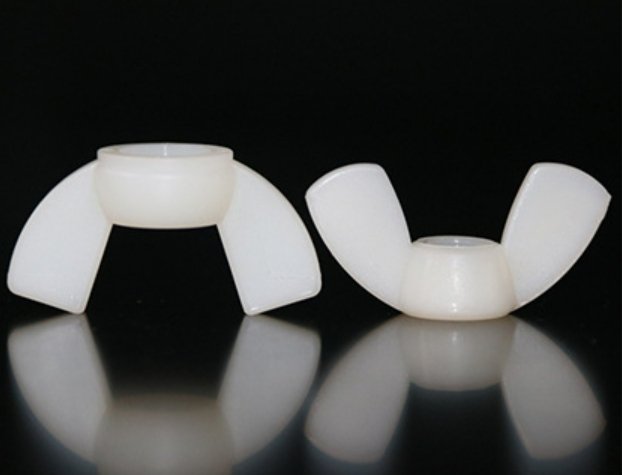

Butterfly nut

Butterfly nut, also known as a wing nut, is a type of fastener designed for hand-tightening and removal without the need for tools

M Size: M4-M12

peek plastic material: PA66/PP/POM

product type: Nuts

COLOR:Naturalcolor/pink/blue/orange.Othercolorscanbe Customizable

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

Overview of Butterfly nut

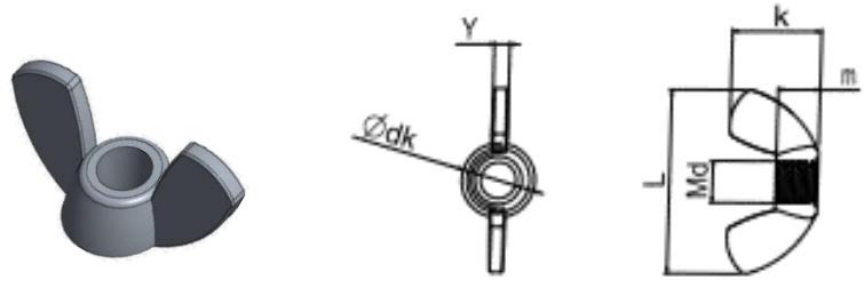

Butterfly nut, also known as a wing nut or butterfly wing nut, is a type of hand-tightened nut designed for easy installation and removal without tools. Its two protruding “wings” allow users to apply torque manually, making it ideal for assemblies that require frequent adjustment or quick disassembly.

Butterfly nuts are commonly paired with Butterfly Screws, a wing screw, or a standard bolt to form assemblies such as:

butterfly nut and bolt

bolt with butterfly nut

bolt and butterfly nut

butterfly bolt and nut

butterfly nut bolt

Key Features of Butterfly Nuts

The fundamental properties of the butterfly nut are dictated by its material and design:

Tool-Free Fastening: The primary characteristic, enabling rapid operation without specialized tools.

Material Versatility: Available in materials suited for different environments:

Brass wing nut: Excellent corrosion resistance, often used in decorative or marine environments.

Plastic wing nut: Lightweight, non-conductive, and economical.

Heavy duty wing nut: Often manufactured from cold-forged steel or high-grade stainless steel for increased strength.

Standard Compatibility: Designed to fit standard thread specifications, making it fully compatible with any standard bolt in a butterfly nut and bolt assembly.

Dimensional Specification: Specific sizing is denoted by thread diameter and pitch, e.g., M6 wing nut or M8 butterfly nut.

Applications

butterfly nut is essential wherever quick adjustments, frequent disassembly, or tool accessibility is a factor:

Fixtures and Jigs: Securing temporary components in workshops, manufacturing, or testing environments that require frequent modification.

Consumer Products: Used in tripods, camera mounts, bicycle seats, and furniture that users need to adjust frequently without a toolbox. The related wing nut screw is often seen here.

Electrical Connections: Wing nuts are common for securing cable leads to battery terminals or power sources, ensuring a quick, secure, and tool-free connection.

Hobby and DIY: Fastening small access covers, enclosures, and adjustable brackets, particularly those involving a bolt and butterfly nut assembly.

Industrial Equipment: Securing inspection panels, covers on machinery, and components in ventilation systems where maintenance is required regularly

Advantages and Disadvantages

Advantages (Pros)

The primary advantage of the butterfly nut centers on its accessibility and ease of use:

Tool-Free Operation: The most significant benefit is the ability to secure or loosen the nut rapidly using only human hand grip. This eliminates the necessity of carrying or locating specific tools (wrenches or sockets), making it highly user-friendly.

Speed of Assembly and Adjustment: For applications requiring frequent modifications, inspections, or repeated disassembly (such as theatrical rigging, tripod adjustments, or securing access panels), the wing nut significantly reduces the time required for maintenance or setup.

Accessibility in Tight Spaces (Manual): While the nut itself is bulky, its hand-operated nature is advantageous in situations where an open-ended wrench or socket might not easily fit or access the fastener head.

Cost-Effective Simplicity: For manufacturers, using a wing nut simplifies product instructions and reduces the need to supply tools to the end-user, thereby streamlining the final assembly process.

Disadvantages (Cons)

The limitations of the butterfly nut are rooted in the mechanical restriction of manual torque application:

Low Clamping Force (Torque Limitation): The achievable tightening torque is inherently limited to the strength of a person’s hand. This makes the butterfly nut unsuitable for high-load, critical structural applications that demand a specific, high-tension preload to function reliably.

Vulnerability to Loosening: Due to the limited installation torque, the nut is highly susceptible to gradual loosening when exposed to prolonged vibration or cyclical dynamic stress. This often necessitates the use of additional locking hardware (like lock washers) if used in vibrating machinery.

Bulk and Space Consumption: The large, projecting wings occupy significant lateral space. This bulkiness can interfere with nearby components and makes the nut impractical for use in assemblies that are densely packed or where clearance is minimal.

Risk of Snagging and Damage: The exposed wings present a physical protrusion that can be easily snagged, caught on clothing, or damaged (bent or broken) if the equipment is mishandled or dropped.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.