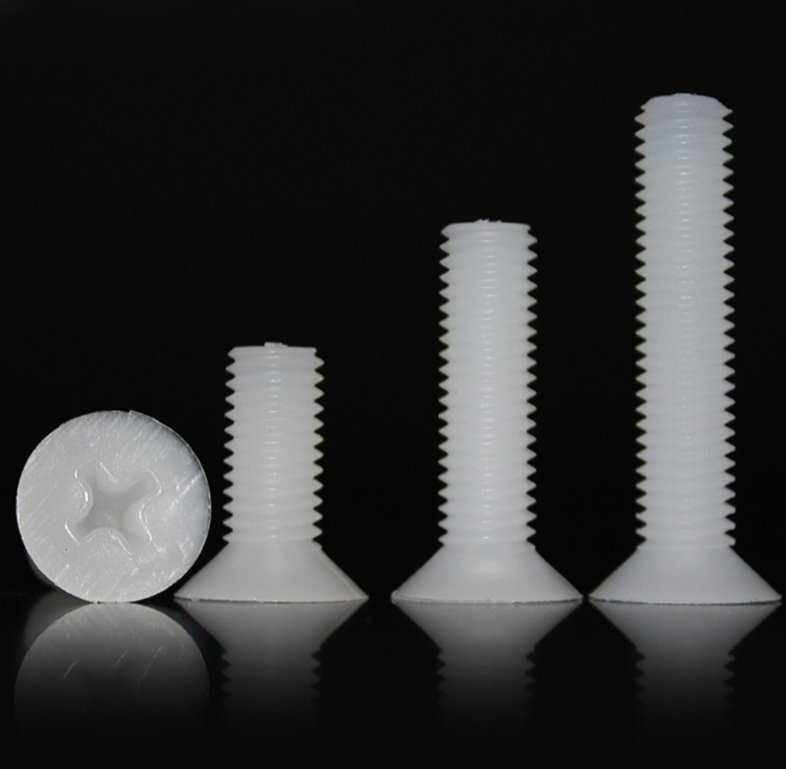

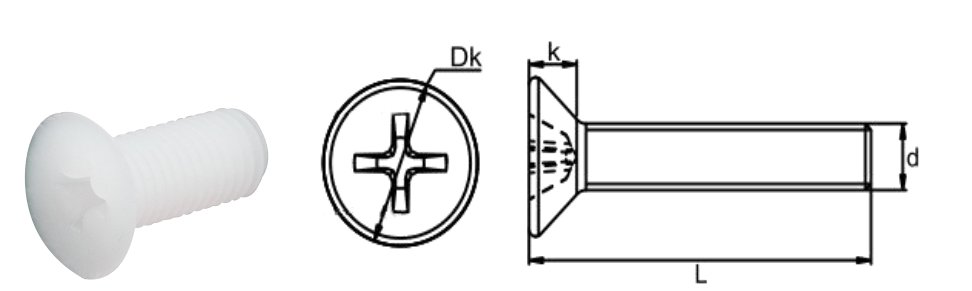

PVDF Cross counter sunk head screw

PVDF Cross counter sunk head screw is a polymer engineering plastic with excellent chemical and weather resistance, and excellent UV resistance and aging resistance.

M Size: M2-M10

peek plastic material: Polyvinylidene fluoride(PVDF)

product Type: Countersunk bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVDF Cross counter sunk head screw Overview

PVDF (Polyvinylidene Fluoride) Cross Countersunk Head Screws are high-performance fluoropolymer fasteners designed for chemical resistance, outdoor durability, UV stability, and excellent electrical insulation. They provide the same flush-mount design as metal countersunk bolts, countersunk head bolts, and phillips head bolts, but with the added benefits of corrosion resistance and lightweight polymer construction.

Key Features

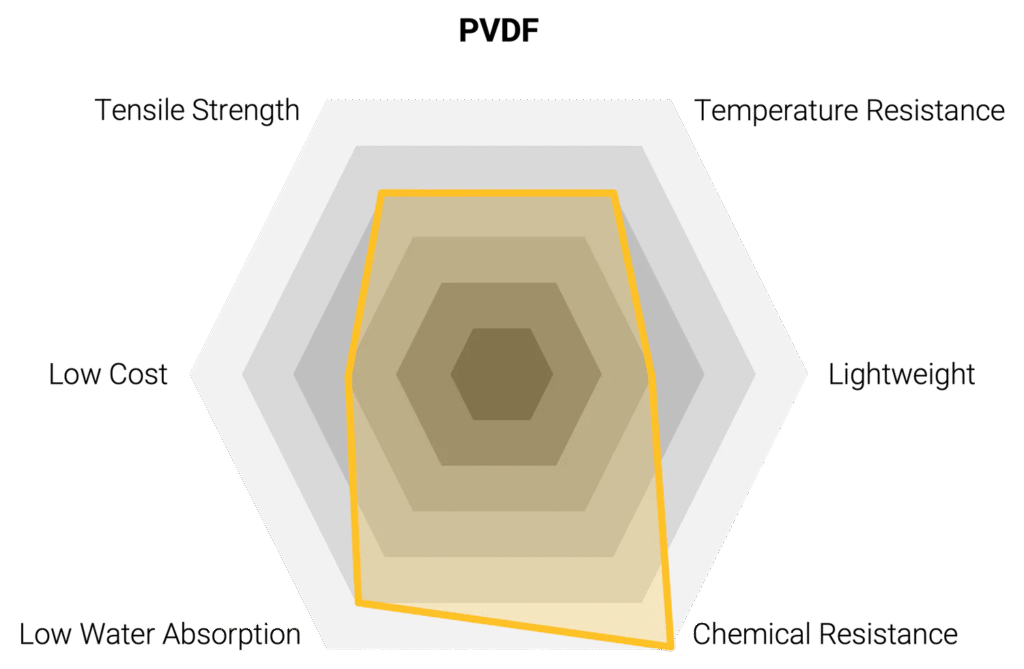

PVDF screws are valued for their toughness and wide resistance profile, making them a popular choice for replacing corroding metal countersunk bolts and even certain grades of countersunk stainless bolts.

Excellent Abrasion Resistance: PVDF is highly tough and resists wear better than most other fluoropolymers (like PTFE), making it ideal for systems with high particulate content or moving parts.

Superior Chemical Resistance: Highly stable against halogens, strong acids, weak bases, and organic solvents. This resistance is key in chemical processing.

Good Mechanical Strength: Offers better strength, stiffness, and creep resistance than PTFE, making it a more dependable structural fastener within the polymer category.

Broad Temperature Range: Maintains stability and performance from low temperatures up to approximately 150°C (300°C).

UV and Weather Resistance: Excellent inherent resistance to UV light and weathering, making it suitable for long-term outdoor applications.

Key Polyvinylidene fluoride (PVDF) Properties

Advantages and Disadvantages (Pros and Cons)

The choice of PVDF involves balancing its superior toughness and weather resistance against the absolute thermal stability of PFA or the structural strength of metal bolt assemblies.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Environmental Performance | Superior Abrasion and UV Resistance compared to PTFE and PFA. Excellent Chemical Resistance and Low Moisture Absorption. | Lower Max Temperature: Maximum continuous service temperature is lower than PFA or PEEK. |

| Mechanical Performance | Good Strength and Stiffness (better than PTFE). Toughness and Resilience. | Solvent Sensitivity: Can swell or dissolve when exposed to highly polar solvents (e.g., strong ketones, amides). |

| Cost | Provides a cost-effective, tough alternative to higher-cost fluoropolymers (PFA, PEEK). | Limited Application Torque: Cannot withstand the high installation torque of metal countersunk bolts. |

Applications

PVDF screws are specified in demanding industrial and sanitary applications where chemical resistance is essential, and good mechanical performance is required.

Semiconductor Wet Benches: Used extensively in the construction of ultra-pure water (UPW) and chemical delivery systems due to its purity and chemical stability.

Chemical Processing: Fastening pipe fittings, valves, and liners exposed to concentrated halogens and oxidizing agents.

Nuclear and Waste Treatment: Used in environments requiring radiation resistance and chemical stability.

Outdoor Applications: Ideal for structures or equipment exposed to weather and corrosive atmospheres due to its UV resistance.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.