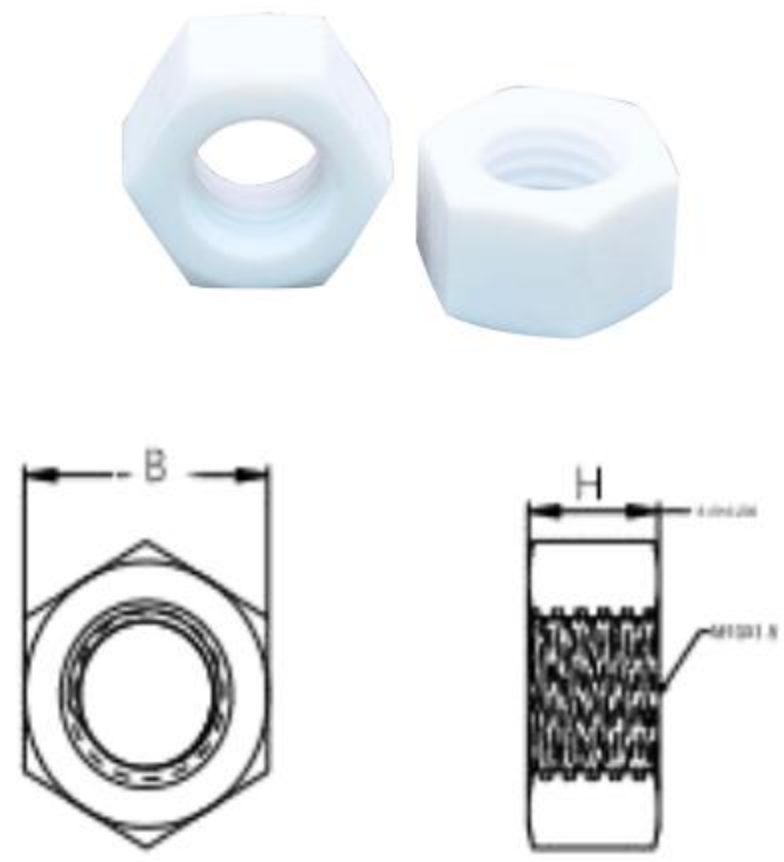

PTFE Hex nut

PTFE Hexagon nut has excellent chemical stability, corrosion resistance, heat resistance and cold resistance, flame retardant grade UL94 V-0, and can be used for a long time at -190~260℃.

M Size: M3-M30

peek plastic material: Polytetra fluoroe thylene(PTFE )

product Type: Nuts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PTFE Hex nut Overview

PTFE hexagon nut, also called a PTFE hex nut, is a six-sided fastener made from Polytetrafluoroethylene (PTFE, Teflon).PTFE nuts are defined by their near-universal chemical inertness, extremely low coefficient of friction, and wide operational temperature range, making them the gold standard for fastening, sealing, and isolation in the most hostile and demanding environments.

Product Parameters

PTFE Hexagon Nuts generally follow established metric standards for regular hexagon nuts, such as ISO 4032, ensuring compatibility with standard bolts and threaded rods.

| Nominal Size (Bolt d) | Thread Pitch (P) | Across Flats (s) | Nut Height (m) |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm |

| M5 | 0.8 mm | 8.0 mm | 4.7 mm |

| M6 | 1.0 mm | 10.0 mm | 5.2 mm |

| M8 | 1.25 mm | 13.0 mm | 6.4 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 10.0 mm |

| M16 | 2.0 mm | 24.0 mm | 13.0 mm |

Key Features

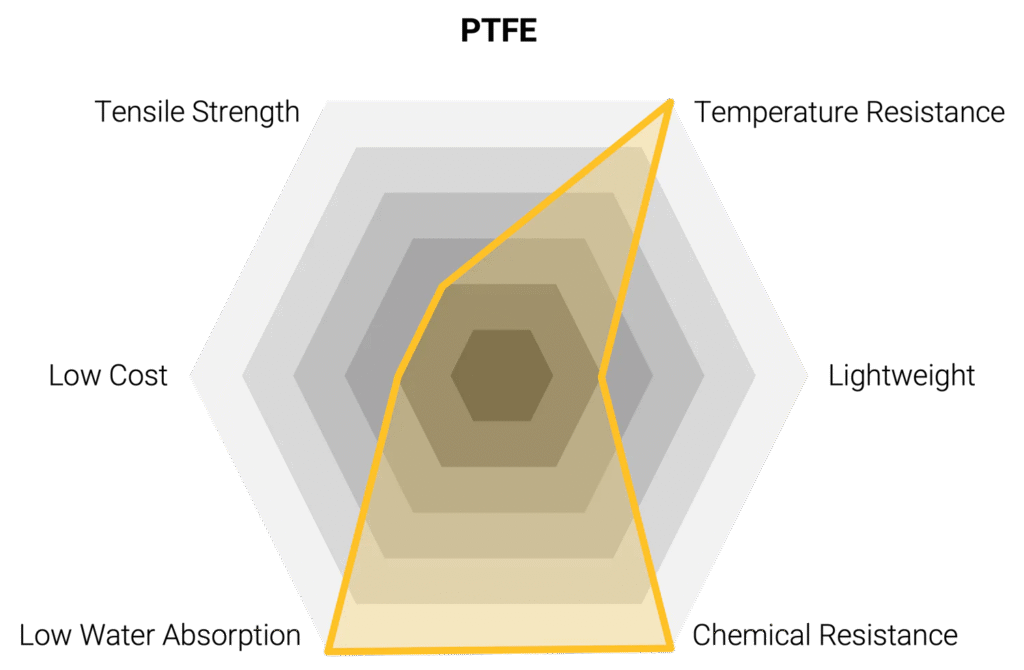

PTFE’s unique molecular structure provides its industry-leading characteristics:

Universal Chemical Inertness: PTFE is virtually non-reactive to almost all chemicals, solvents, and corrosive agents up to high temperatures, making it the most chemically resistant solid fastener available.

Wide Temperature Range: Highly stable from cryogenic temperatures (down to 220°C up to 260°C(500°C), far exceeding the thermal capabilities of nylon hex nut.

Lowest Coefficient of Friction: PTFE has an exceptionally low coefficient of friction, making it self-lubricating, which prevents seizing and galling in a hex nut screw assembly.

Excellent Dielectric Properties: It is an outstanding electrical insulator, highly valued in high-frequency and critical isolation applications.

Non-Stick Surface: Its surface prevents adhesion, minimizing material build-up and contamination.

Dimensional Compliance: Manufactured to adhere to precise hex nut diameter and hex nut height standards, although its flexibility must be considered.

Key Polytetrafluoroethylene (PTFE) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Chemical & Thermal | Unmatched Inertness: Resistant to virtually all chemicals across the widest temperature range. Wide Operating Span: Functions reliably from 200°C to 260°C. | Cold Flow (Creep): PTFE is highly prone to cold flow (deformation under sustained compression), severely limiting its load-bearing capacity and torque retention. |

| Functionality | Lowest Friction: Prevents seizing; self-lubricating. Excellent Isolation: Reliable electrical and thermal barrier. | Low Mechanical Strength: Cannot withstand the high clamp loads typically achieved with metal hex nuts (even stainless steel hex nuts), making it unsuitable for high-stress applications. |

| Comparison | Superior chemical and thermal resistance to nylon hex nut. Solves the lock nut vs hex nut dilemma when corrosion is the primary failure mode. | Cost: PTFE is a high-cost material, making its use cost-prohibitive for non-critical, general-purpose applications. |

| Installation | Available in standard metric hex nuts and imperial sizes. | Torque Limitations: Requires extremely low installation torque. The low compression strength means standard installation protocols with a nut driver hex cannot be followed. |

Applications

PTFE Hexagonal Nuts are indispensable in industries where purity, extreme chemical survival, and thermal stability are paramount.

Chemical and Pharmaceutical Manufacturing: Used in pumps, valves, and piping as a fastener and seal against highly corrosive chemicals and solvents at extreme temperatures.

Cryogenics and Aerospace: Employed due to its ability to maintain integrity and flexibility at extremely low temperatures.

Fastener Isolation: Used to separate metal fasteners (preventing galvanic corrosion) or to ensure chemical isolation in highly corrosive environments where a hex bolt nut assembly must remain non-reactive.

High-Frequency Electronics: Used as an insulator due to its superior dielectric properties.

Food and Beverage Processing: Utilized in contact with food and beverages due to its non-toxic, non-stick properties.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.