PTFE Flat washer

PTFE Flat washer has excellent chemical stability, corrosion resistance, heat resistance and cold resistance, flame retardant grade UL94 V-0, and can be used for a long time at -190~260℃.

M Size: M3-M30

peek plastic material: Polytetra fluoroe thylene(PTFE )

product Type: Washers

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PTFE Flat washer Overview

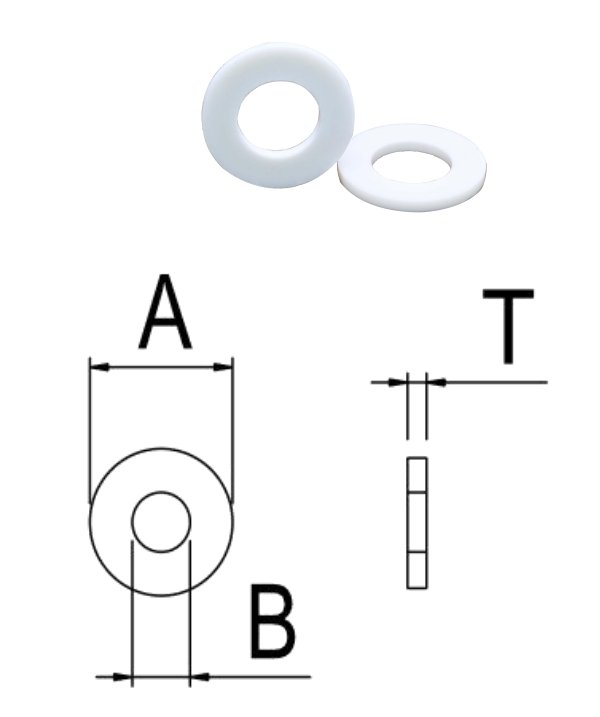

PTFE Flat Washer is a highly specialized, non-metallic component made from Polytetrafluoroethylene (PTFE), universally known by the trade name Teflon. PTFE washers are distinguished by their near-universal chemical inertness, exceptionally low coefficient of friction, and wide operational temperature range.

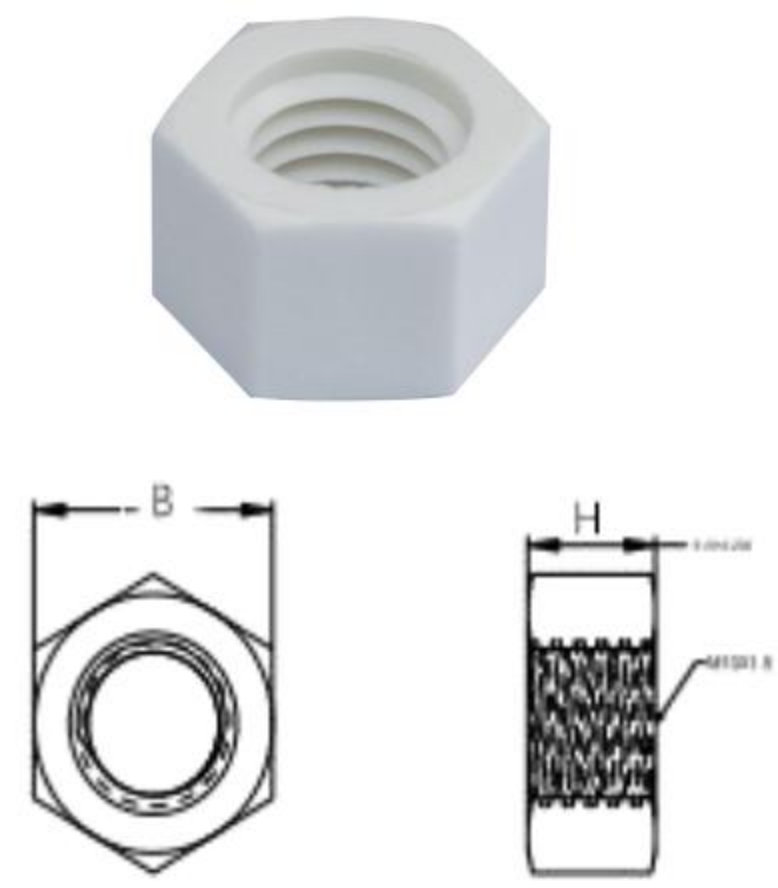

Product Parameters

PTFE Flat Washers generally adhere to established metric standards for plain washers, such as ISO 7089 (Non-chamfered) or ISO 7090 (Chamfered), with dimensions defined by the inner diameter (ID), outer diameter (OD), and thickness (T).

| Nominal Size (Bolt d) | Inner Diameter (ID) | Outer Diameter (OD) | Thickness (T) |

| M4 | 4.3 mm | 9.0 mm | 0.8 mm |

| M5 | 5.3 mm | 10.0 mm | 1.0 mm |

| M6 | 6.4 mm | 12.0 mm | 1.6 mm |

| M8 | 8.4 mm | 16.0 mm | 1.6 mm |

| M10 | 10.5 mm | 20.0 mm | 2.0 mm |

| M12 | 13.0 mm | 24.0 mm | 2.5 mm |

| M16 | 17.0 mm | 30.0 mm | 3.0 mm |

Key Features

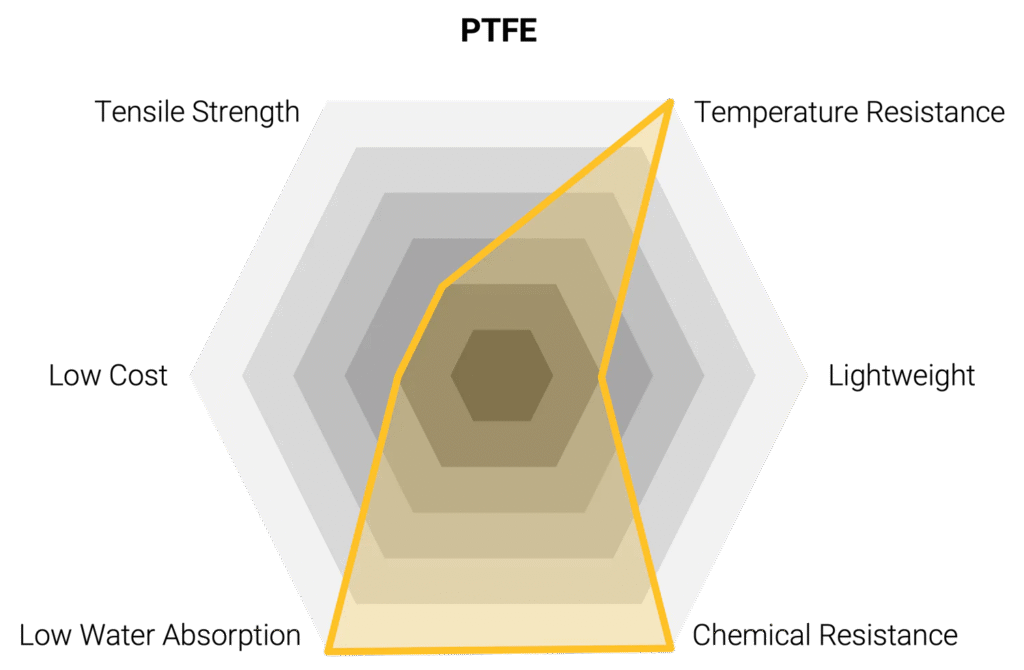

PTFE’s unique molecular structure provides its industry-leading characteristics:

Universal Chemical Inertness: PTFE is virtually non-reactive to almost all chemicals, solvents, and corrosive agents, making it the most chemically resistant solid material available.

Wide Temperature Range: It is highly stable across an extremely broad temperature spectrum, typically from 190°C (328°C) up to 260°C (500°C).

Lowest Coefficient of Friction: PTFE has an exceptionally low coefficient of friction, making it self-lubricating and ideal for use as a bearing or sliding surface, often replacing a flat rubber washer where sliding is required.

Excellent Dielectric Properties: It is an outstanding electrical insulator, highly valued in high-frequency electrical applications.

Non-Stick Surface: Its surface prevents adhesion, minimizing material build-up in processing lines.

Flexibility and Conformity: PTFE is relatively soft, allowing it to conform well to uneven surfaces, enhancing its sealing capability beyond simple load distribution.

Key Polytetrafluoroethylene (PTFE) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Chemical & Thermal | Unmatched Inertness: Resistant to virtually all chemicals across a wide temperature range. Wide Operating Span: Functions reliably from cryogenic to high heat (260°C). | Cold Flow (Creep): PTFE is prone to cold flow (deformation under sustained compression), limiting its use in high-torque or high-compression applications. |

| Functionality | Lowest Friction: Excellent self-lubricating properties, ideal for dynamic loads. Excellent Electrical Insulator. | Low Load Bearing: Due to its softness, it has low resistance to crushing and cannot withstand the high clamp loads typically achieved with metal flat washer or flat lock washer assemblies. |

| Comparison | Superior chemical and thermal resistance to washer flat nylon. Addresses the core issues of galvanic corrosion and chemical attack better than stainless flat washer. | Cost: PTFE is a high-cost material, making its use prohibitively expensive for non-critical, general-purpose applications. |

| Procurement | Available in precise dimensions conforming to flat washer specs and sizing standards. | Sourcing: Requires sourcing from specialized suppliers due to its high-end material status, unlike common flat wash products. |

Applications

PTFE Flat Washers are indispensable in industries where purity, chemical survival, and thermal stability are paramount.

Chemical and Pharmaceutical Manufacturing: Used in pumps, valves, and piping as a seal or barrier against highly corrosive chemicals and solvents at elevated temperatures.

Cryogenic Applications: Used due to its ability to maintain flexibility and strength at extremely low temperatures.

High-Frequency Electronics: Employed as an insulator due to its excellent dielectric properties and high thermal stability.

Food and Beverage Processing: Utilized in food-contact equipment due to its non-toxic, non-stick, and easily cleanable surface.

Fastener Isolation: Used to separate metal fasteners (preventing galvanic corrosion) or to ensure thread sealing in low-torque, chemically-active assemblies, often chosen over a metal flat lock washer for its chemical properties.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.