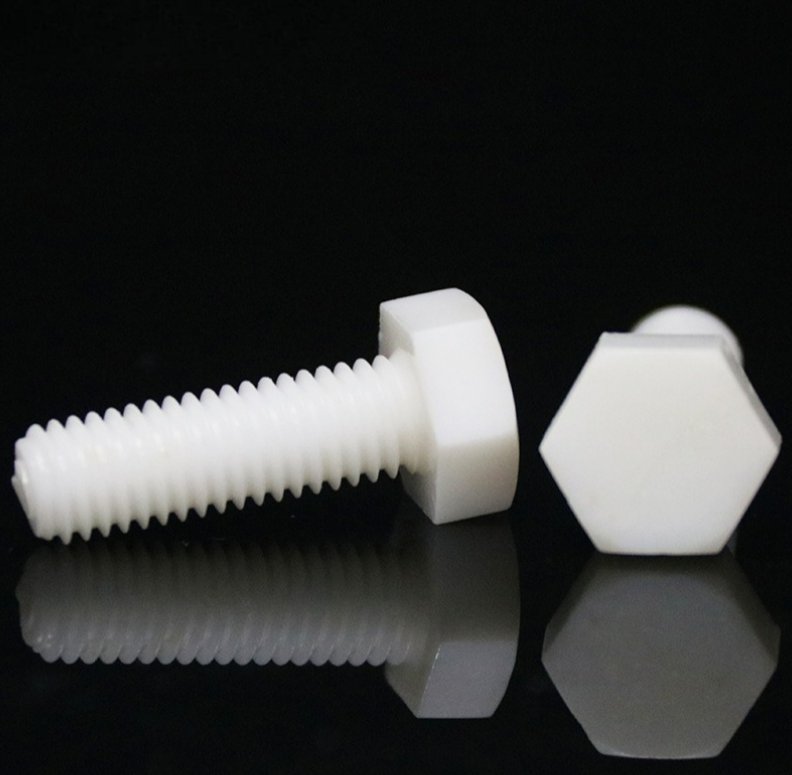

ZrO2 Hexagon head bolt

ZrO2 Hexagon head bolts are corrosion-resistant, wear-resistant, high-temperature-resistant, insulating, non-magnetic, and high-purity.

M Size: M4-M12

peek plastic material: Zirconia ceramic fasteners

product Type: Hexagon head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

ZrO2 Hexagon head bolt Overview

ZrO2 (Zirconium Dioxide, or Zirconia Ceramic) Hexagon Head Bolt is an ultra-high-performance ceramic structural fastener. It is primarily selected for its extreme hardness, exceptional mechanical strength, superior wear resistance, and high-temperature stability. The Hexagon Head design is essential for allowing controlled, secure torque application. ZrO2 ceramics are non-metallic and non-magnetic, making these bolts indispensable in environments where the combination of high mechanical load, high heat, and chemical inertness is required, surpassing the limits of polymers and most metals.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (ZrO2 Ceramic) | Zirconium Dioxide (Yttria-Stabilized Zirconia, Y-TZP). A structural ceramic known for its highest toughness among advanced ceramics (due to transformation toughening). | Provides a fastener that is virtually immune to corrosion, wear, and high temperatures, while offering high strength for structural assemblies. |

| Design (Hex Head) | Standard six-sided external head. | Allows for external wrench tightening, enabling the maximum controlled torque and clamping force achievable with ZrO2 material. |

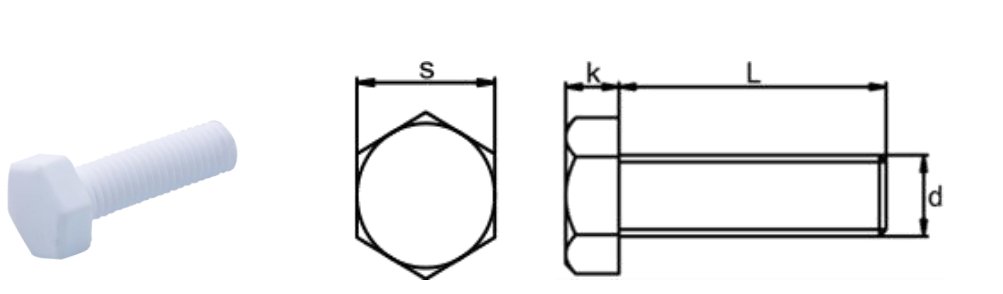

Product Parameters

ZrO2 Hexagon Head Bolts typically follow established metric standards for hexagon head bolts, such as ISO 4014 (partially threaded) or ISO 4017 (fully threaded).

| Nominal Diameter (d) | Thread Pitch (P) | Across Flats (s) | Head Height (k) |

| M5 | 0.8 mm | 8.0 mm | 3.5 mm |

| M6 | 1.0 mm | 10.0 mm | 4.0 mm |

| M8 | 1.25 mm | 13.0 mm | 5.3 mm |

| M10 | 1.5 mm | 16.0 mm | 6.4 mm |

| M12 | 1.75 mm | 18.0 mm | 7.5 mm |

| M16 | 2.0 mm | 24.0 mm | 10.0 mm |

Key Features

ZrO2 is one of the toughest and most durable advanced ceramic materials, ideal for structural fastening in extreme environments:

Extreme Hardness & Wear Resistance: Maintains performance in highly abrasive or erosive environments, providing a long service life.

Highest Toughness (among ceramics): Known for its ability to resist crack propagation through “transformation toughening,” improving reliability over other ceramics.

Ultra-High Temperature Stability: Maintains mechanical strength and dimensional stability at temperatures well above 1000°C.

Chemical Inertness: Almost completely immune to corrosion from acids, alkalis, and strong chemicals.

Non-Conductive & Non-Magnetic: Ideal for high-voltage electrical insulation and use in sensitive magnetic resonance environments.

Advantages and Disadvantages and Usage Scenarios

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Extreme toughness and high mechanical strength. Exceptional wear resistance and dimensional stability under load. | Very High Cost: One of the most expensive fasteners due to raw material and complex sintering/machining processes. | High-Wear Machinery: Structural fastening in high-speed, abrasive fluid transfer, or sliding components where metal wear is unacceptable. |

| Material | Ultra-high temperature stability and complete chemical inertness. Non-conductive and non-magnetic. | Brittleness: Still brittle compared to steel; susceptible to catastrophic failure from excessive impact/shock loading. | Furnaces and Kilns: Securing high-temperature structural components in oxidative or reducing atmospheres (above 1000°C). |

| Design | Hex Head allows for high, controlled torque and secure, structural clamping. | Installation Risk: Must be installed with precise, controlled torque to avoid stress-induced cracking in the thread roots. | Magnetic Resonance (MRI): Securing non-metallic, structural equipment within strong magnetic fields. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.