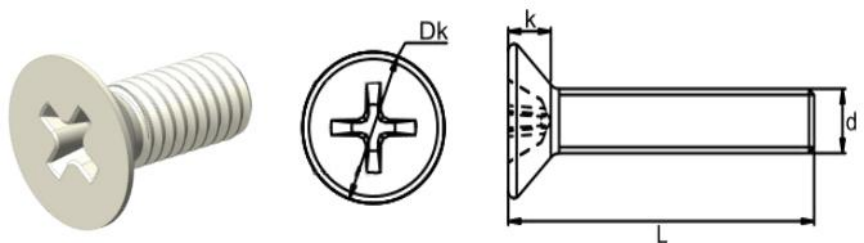

PFA Cross counter sunk head screw

PFA Cross counter sunk head screw is known as the “King of Plastics”. It is corrosion-resistant and electrically insulating.

M Size: M4-M10

peek plastic material:Polyvinylidenefluoride(PFA)

product type: Countersunk bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PFA Cross counter sunk head screw Overview

PFA Cross Countersunk Head Screws are high-performance plastic screws made from PFA (Perfluoroalkoxy Alkane), a premium fluoropolymer known for extreme chemical resistance, high purity, and excellent temperature endurance. With a countersunk head design, these screws provide a smooth, flush finish similar to metal countersunk bolts or countersunk head bolts, while offering superior corrosion resistance in harsh chemical environments.

Product Parameters

PFA countersunk bolts are manufactured to precise standards, often aligning with metric sizes common in high-tech manufacturing, such as countersunk m4 bolts and larger imperial sizes like 3/8 countersunk bolt.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) |

| M3 | #4 | 6.0 mm / 0.24 in |

| M4 (Countersunk M4 bolts) | #6 | 8.0 mm / 0.31 in |

| M6 | 1/4″ | 12.0 mm / 0.47 in |

| M10 | 3/8″ (3 8 countersunk bolt) | 18.0 mm / 0.71 in |

Key Features

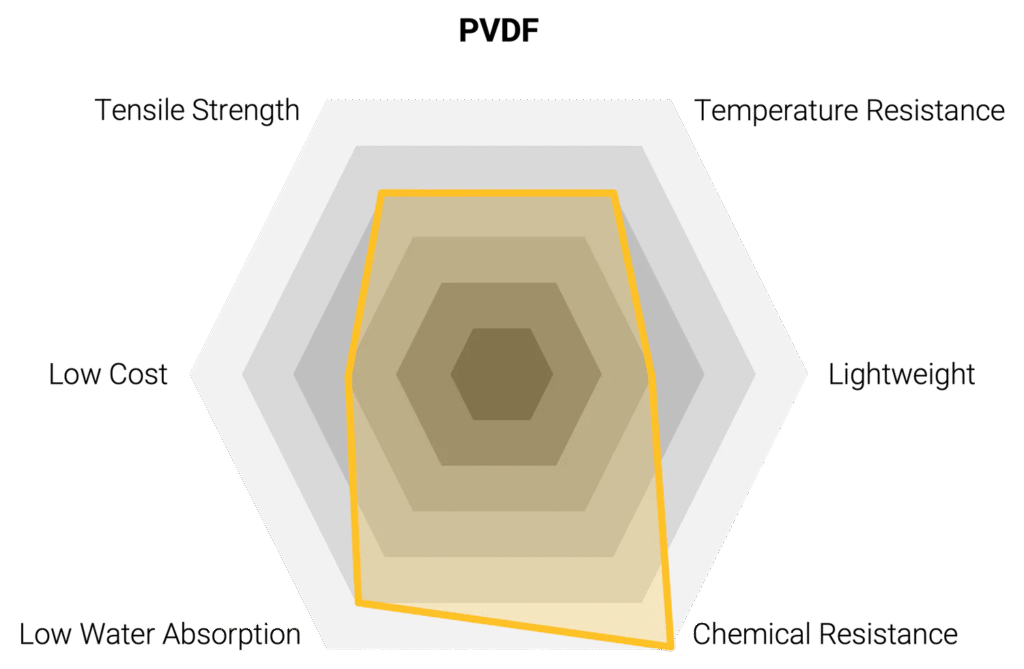

PFA screws are chosen when performance cannot be compromised. Their characteristics surpass most other plastic screws, including Nylon and PVC.

Chemical Inertness: PFA is almost entirely chemically inert. It resists virtually all solvents, acids, and bases, making it unparalleled in corrosive media.

Thermal Stability: PFA maintains structural integrity and strength across an extremely wide temperature range, from cryogenic lows up to 260°C (500°C).

Ultra-High Purity: PFA is non-leaching, non-contaminating, and has a smooth surface finish, which prevents particle entrapment—critical for ultra-pure water (UPW) systems.

Non-Stick Properties: Inherently low friction and non-stick, which is advantageous in fluid handling components.

Excellent Dielectric Properties: Superb electrical insulation, maintaining performance across various frequencies and temperatures.

Key Perfluoro alkoxyalkane (PFA) Properties

Advantages and Disadvantages (Pros and Cons)

The choice of PFA involves weighing its elite performance against its inherent material limitations and cost.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Environmental Performance | Universal Chemical Inertness and Extremely Wide Temperature Range. Non-leaching Ultra-High Purity. | Lower Mechanical Strength: Significantly weaker than steel or titanium countersunk bolts. Requires careful torque control. |

| Design & Material | Flush Surface: Countersunk head bolt provides smooth, clean finish. Excellent Electrical Insulator. | High Cost: PFA is one of the most expensive engineering plastics, limiting its use to essential components. |

| Installation | Compatible with standard Phillips head bolts tools. | Creep/Cold Flow: Like all fluoropolymers, PFA can exhibit cold flow under constant heavy load, requiring periodic re-tightening. |

Applications

PFA screws are typically found only in mission-critical applications where high cost is justified by the requirement for absolute reliability and zero contamination.

Semiconductor Manufacturing: Securing components in wet etching tools, chemical delivery systems (CDS), and ultra-pure water (UPW) systems where failure is not an option.

Pharmaceutical and Biotech: Applications requiring sterile environments and resistance to aggressive cleaning agents (CIP/SIP).

Aerospace: Used where lightweight, non-flammable, and chemically resistant screws are necessary, often replacing heavy metal bolt assemblies.

Laboratory Equipment: Fastening components in analytical instruments, reactors, and high-heat furnaces.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.