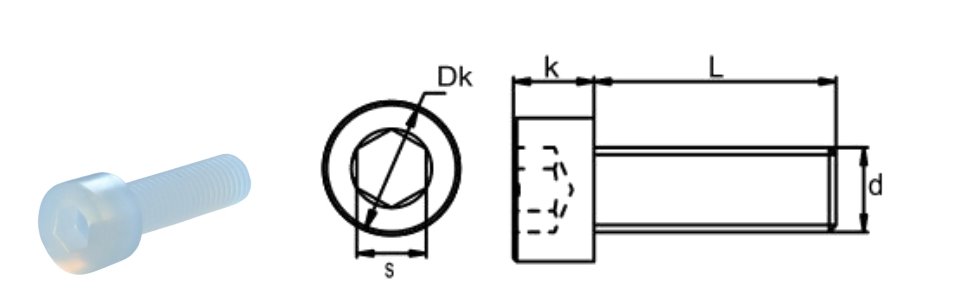

PPS Hexagon socket head screw

PPS Hexagon socket head screw are made of a hard, highly rigid material with excellent heat resistance, chemical resistance, and dimensional stability.

M Size: M3-M12

peek plastic material: Polyetherether ketone(PPS)

product type: Hexagon socket head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PPS Hexagon socket head screw Overview

PPS (Polyphenylene Sulfide) Hexagon Socket Head Screw (also known as a socket head cap screw) is a high-performance, robust plastic screw utilized in demanding applications requiring exceptional chemical and thermal resistance combined with high mechanical stiffness. The Hexagon Socket (Allen drive) allows for the highest and most controlled installation torque achievable with PPS, maximizing the strength of the non-metallic assembly.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PPS) | Polyphenylene Sulfide. A semicrystalline polymer with high mechanical strength, dimensional stability, and service temperature up to 220°C. | Ensures the fastener maintains structural integrity and chemical immunity under extreme operating conditions. |

| Head Style (Cylindrical Socket Head) | A tall, cylindrical head with a flat top. | Provides a large bearing surface and maximum shear resistance for a PPS screw. |

| Drive Style (Hexagon Socket) | The Allen drive recess. | Allows for the maximum installation torque achievable with PPS, minimizing the risk of stripping the recess or cam-out. |

Product Parameters

PPS Hexagon Socket Head Screws typically follow metric standards for socket head cap screws, such as ISO 4762 (equivalent to DIN 912).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Socket Size (S) |

| M3 | 0.5 mm | 5.5 mm | 3.0 mm | 2.5 mm |

| M4 | 0.7 mm | 7.0 mm | 4.0 mm | 3.0 mm |

| M5 | 0.8 mm | 8.5 mm | 5.0 mm | 4.0 mm |

| M6 | 1.0 mm | 10.0 mm | 6.0 mm | 5.0 mm |

| M8 | 1.25 mm | 13.0 mm | 8.0 mm | 6.0 mm |

| M10 | 1.5 mm | 16.0 mm | 10.0 mm | 8.0 mm |

Key Features

The Hexagon Socket Head design, combined with PPS material, provides a fastener optimized for high performance and secure assembly:

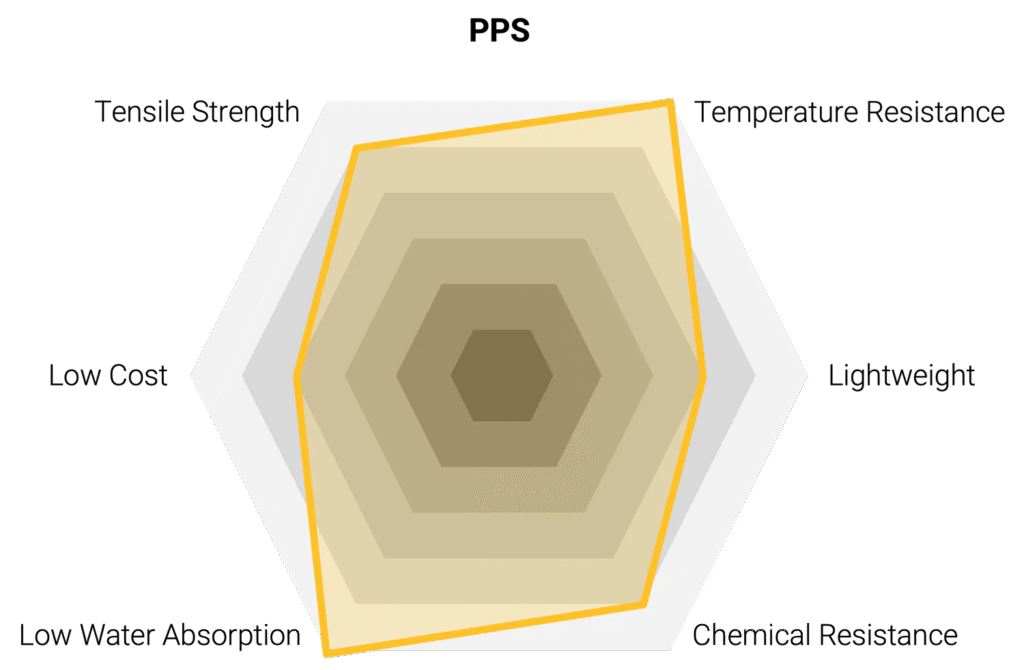

Superior Environmental Resistance: Maintains integrity at continuous temperatures up to 220°C and resists a vast range of aggressive chemicals, solvents, and fuels.

Highest Torque for PPS: The socket drive allows the screw to be tightened closer to the material’s maximum yield strength without damaging the drive recess.

High Mechanical Stiffness: Very rigid, offering excellent resistance to creep (deformation under sustained load) and maintaining thread engagement at high temperatures.

High Shear Strength: The robust cylindrical head profile offers excellent resistance to lateral forces.

Non-Conductive & Non-Magnetic: Essential for electrical and sensitive instrumentation assemblies.

Key Polypropylene (PP) Properties

Applications

PPS Hexagon Socket Head Screws are critical in industrial applications exposed to severe environments where secure, high-torque fastening is needed:

Chemical Processing: Structural fastening of pumps, valves, and fluid systems where precise torque and resistance to hot, corrosive chemicals are required.

High-Heat Electronics: Mounting insulators, sensors, and structural components in power supplies or controls operating up to 220°C.

Industrial Machinery: Used in assemblies requiring a strong, non-metallic bolt that is resistant to aggressive cleaning agents, oils, and solvents.

Aerospace: Securing internal, non-structural components that must maintain performance under thermal cycling.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Superior chemical and thermal resistance. High rigidity, low creep, and maximum clamping force for PPS. | Lower Impact Strength: More brittle than Nylon or PC; requires care under high impact. |

| Design | Hexagon socket allows for high, controlled torque and requires less radial clearance than a hex head bolt. | High Cost: More expensive than standard polymers, though often necessary for specialized environments. |

| Material | Lightweight, non-corrosive, excellent dimensional stability. | Limited temperature range compared to PEEK (260°C), but still exceptionally high. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.