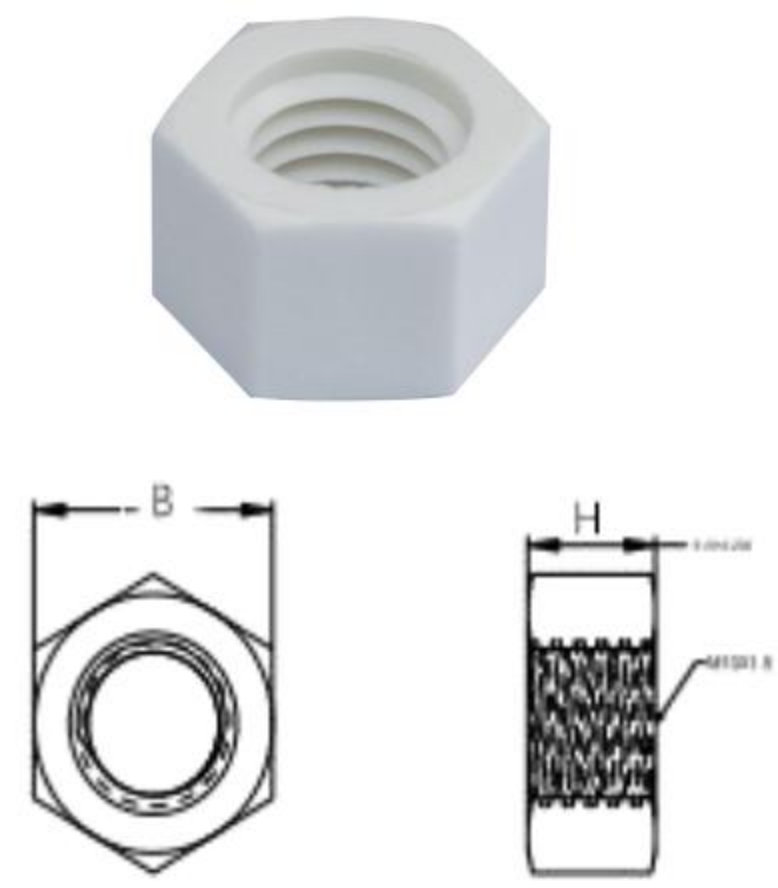

PPS Hex nut

PPS Hex nut are made of a hard, highly rigid material with excellent heat resistance, chemical resistance, and dimensional stability.

M Size: M3-M30

peek plastic material: Polyetherether ketone(PPS)

product type:Nuts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PPS Hex nut Overview

PPS Hex nut is an advanced, high-performance thermoplastic fastener made from Polyphenylene Sulfide. It is primarily selected for applications demanding a combination of excellent thermal stability (up to 200°C), broad chemical resistance, and superior dimensional accuracy. PPS nuts serve as a robust, non-metallic alternative to stainless steel hex nuts and outperform standard plastics like nylon hex nut in high-temperature or chemically aggressive environments.

Product Parameters

PPS Hexagon Nuts typically follow established metric standards for regular hexagon nuts, such as ISO 4032, ensuring compatibility with standard bolts and threaded rods.

| Nominal Size (Bolt d) | Thread Pitch (P) | Across Flats (s) | Nut Height (m) |

| M3 | 0.5 mm | 5.5 mm | 2.4 mm |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm |

| M5 | 0.8 mm | 8.0 mm | 4.7 mm |

| M6 | 1.0 mm | 10.0 mm | 5.2 mm |

| M8 | 1.25 mm | 13.0 mm | 6.4 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 10.0 mm |

| M16 | 2.0 mm | 24.0 mm | 13.0 mm |

Key Features

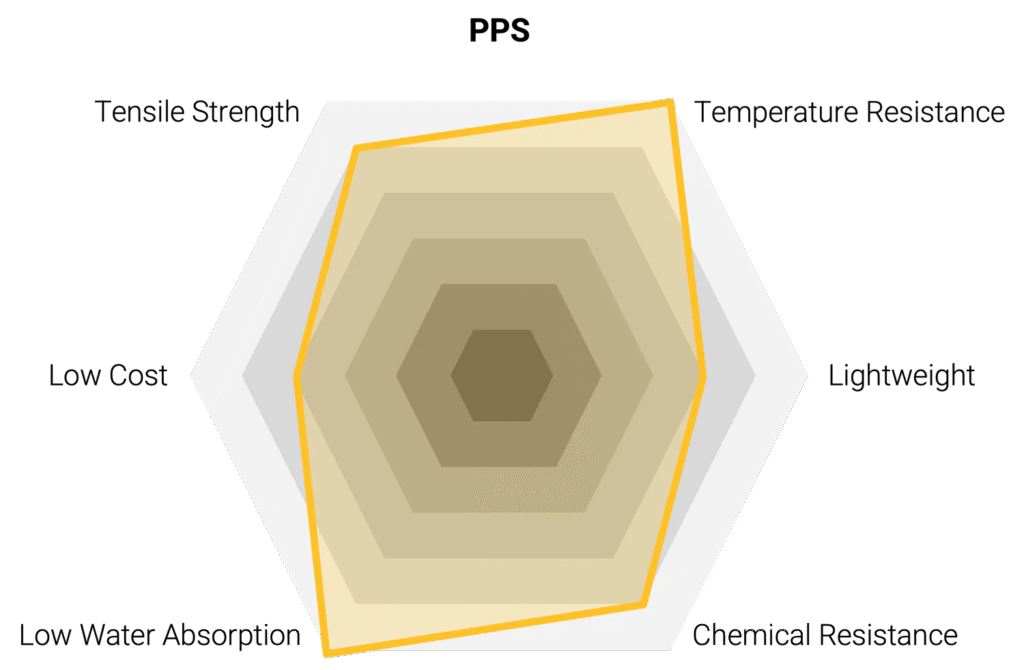

The unique properties of Polyphenylene Sulfide define the features of the PPS Hexagon Nut:

Exceptional Thermal Stability: PPS offers a high continuous service temperature (up to 220°C / $392°C), significantly exceeding most other engineering plastics.

Broad Chemical Resistance: PPS exhibits excellent resistance to a wide range of strong chemicals, including many industrial solvents and acids, even at elevated temperatures.

Excellent Dimensional Stability: It maintains its specified dimensions (hex nut diameter, hex nut height) reliably under load and varying temperatures due to low moisture absorption.

High Rigidity and Stiffness: Provides good mechanical strength and creep resistance, allowing it to sustain more reliable clamp loads than softer polymers in a hex nut bolt assembly.

Inherent Flame Retardancy: PPS typically exhibits self-extinguishing properties without the need for additional chemical additives.

Electrical Isolation: It is inherently non-conductive, providing electrical and thermal isolation in any hex nut screw assembly.

Key Polypropylene (PP) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Thermal & Chemical | High Service Temperature: Operates reliably up to 200°C. Excellent Chemical Resistance: Withstands a broad range of aggressive industrial fluids. | Brittleness: Unfilled PPS can sometimes exhibit a slight tendency toward brittleness, especially when subjected to repeated high impact. |

| Mechanical | High Rigidity: Excellent stiffness and low creep, superior to nylon hex nut. Dimensional Stability: Maintains size precisely under heat. | Cost: While less expensive than PEEK, PPS is significantly more costly than commodity plastics or standard hex nut products. |

| Functionality | Inherent Flame Retardancy. Reliable electrical and thermal isolation. Solves the lock nut vs hex nut dilemma in high-temperature chemical environments. | Torque Limitations: Still a polymer; high compression can lead to internal stress and potential failure, necessitating careful torque control with a nut driver hex. |

| Sourcing | Available in standard formats (metric hex nuts and imperial sizes) for easier integration. | Availability: Not as universally stocked as common stainless steel hex nuts, requiring sourcing from specialized distributors. |

Applications

PPS Hexagon Nuts are critical in industrial and automotive sectors that require stable, non-metallic fastening solutions at high temperatures and in chemically active environments.

Automotive and Engine Compartments: Used in applications exposed to sustained high heat, oil, and automotive fluids where lightweighting and chemical stability are required.

Industrial Furnaces and Ovens: Employed as insulators and fasteners in equipment exposed to high operational temperatures.

Chemical Processing: Used in components exposed to corrosive media at elevated temperatures where even corrosion-resistant metal hex nuts might still fail.

Electronics and Appliances: Used in power supplies, electrical insulators, and heat-generating equipment due to its high dielectric strength and thermal rating.

Fastener Isolation: Used as a non-conductive element to prevent galvanic corrosion between metal parts, often chosen over a metal hex lock nuts design for its non-conductive properties.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.