PA66 Slotted counter sunk head screw

PA66 Slotted counter sunk head screw has excellent wear resistance and oil resistance, and it is self-extinguishing (UL94V-2). It is not resistant to strong acids and has high water absorption.

M Size: M2-M10

peek plastic material: Polyamide66(PA66)

product type: Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 Slotted counter sunk head screw Overview

PA66 (Polyamide 66, or Nylon 66) Slotted Countersunk Head Screw is a widely used plastic screw known for its excellent toughness, low friction, and electrical insulation. The Countersunk Head is designed to sit flush with the surface of the material, providing a clean, smooth finish, while the Slotted Drive allows for easy installation.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PA66) | Polyamide 66 (Nylon 66). A high-strength, durable engineering plastic. | Provides excellent mechanical properties, non-conductivity, and resistance to abrasion at a cost-effective price. |

| Head Style (Countersunk) | Features a flat top surface and a tapered underside (conical). | Designed to recess into a prepared hole, allowing the head to sit flush with the surface for a smooth, clean finish. |

| Drive Style (Slotted) | A simple single slot on the top surface. | Allows for installation using a flat-blade screwdriver; suitable for controlled low torque. |

| Application | Non-corrosive, insulating fastening requiring a smooth, flush surface finish. | Ideal for securing panels, trim, or components that should not impede movement or snag. |

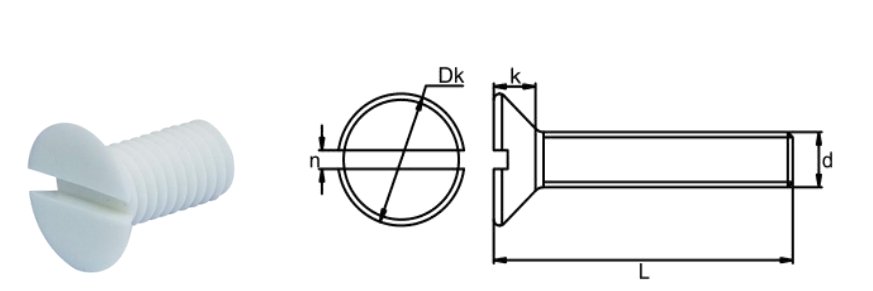

Product Parameters

PA66 Slotted Countersunk Head Screws typically follow metric standards for slotted countersunk head screws, such as ISO 2009 (Slotted Countersunk Flat Head Screws).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Angle | Slot Width (N) |

| M3 | 0.5 mm | 5.6 mm | $90^\circ$ | 0.8 mm |

| M4 | 0.7 mm | 7.5 mm | $90^\circ$ | 1.0 mm |

| M5 | 0.8 mm | 9.2 mm | $90^\circ$ | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | $90^\circ$ | 1.6 mm |

| M8 | 1.25 mm | 14.5 mm | $90^\circ$ | 2.0 mm |

| M10 | 1.5 mm | 18.0 mm | $90^\circ$ | 2.5 mm |

Key Features

PA66 Countersunk Screws offer a crucial aesthetic and functional benefit:

Flush Finish: The head recesses completely, eliminating protrusions and creating a smooth, professional surface finish.

Toughness and Impact Resistance: Highly resistant to breakage and damage from impact, making it very durable.

Electrical Insulation: Excellent dielectric properties, crucial for isolating electrical circuits.

Abrasive Resistance: Good resistance to wear, useful in assemblies that may be frequently cleaned or handled.

Corrosion Immunity: Will not rust or cause galvanic corrosion.

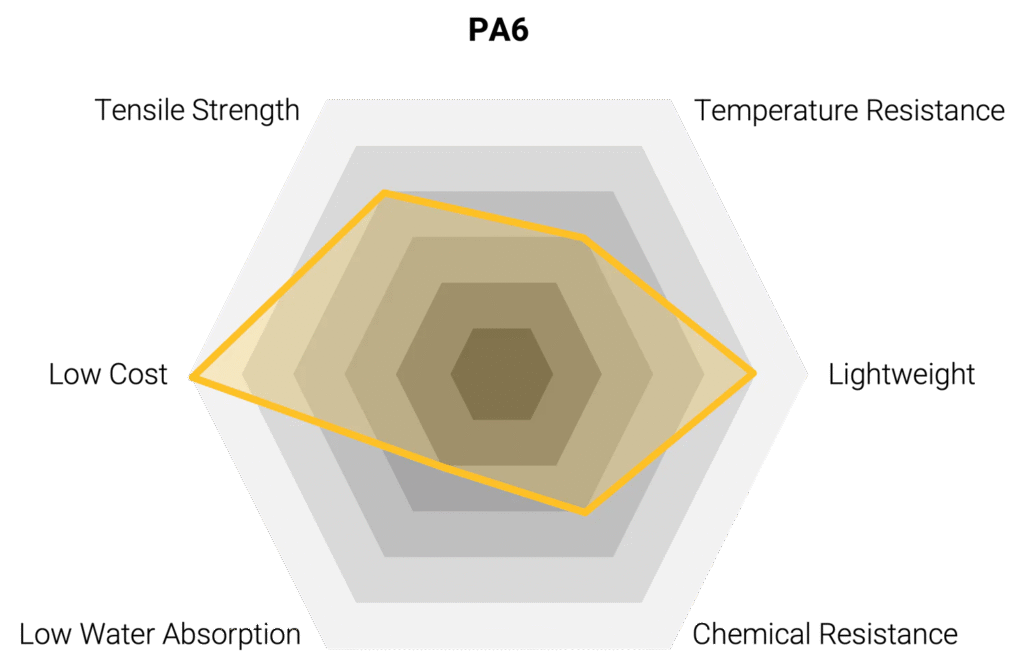

Key Polyamide Nylon (PA6) Properties

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Aesthetics/Function | Creates a smooth, snag-free, flush surface. High mechanical strength for a polymer. | Requires Preparation: Installation requires a precise countersunk hole, adding a step to the assembly process. |

| Material | High toughness and cost-effective. Excellent electrical insulator. | Moisture Absorption: Nylon absorbs water, which can lead to dimensional changes and reduced strength over time. |

| Design | Suitable for applications needing non-metallic strength. | Slotted Drive Limitation: Provides low torque transmission and is prone to cam-out, especially when driving into soft plastic. |

Applications

PA66 Slotted Countersunk Head Screws are commonly used where a clean, safe, and electrically insulated surface is required:

Automotive Interiors: Securing trim, paneling, and dashboard components where a flush fit is necessary for aesthetics and safety.

Electronic Enclosures: Fastening access covers, doors, and internal mounting plates in equipment where the screw head cannot interfere with nearby components.

Appliance Manufacturing: Used on outer surfaces of appliances (e.g., washing machines, dryers) for a smooth, easy-to-clean finish.

Marine: Securing internal deck plates or fittings where corrosion immunity and a trip-hazard-free surface are needed.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.