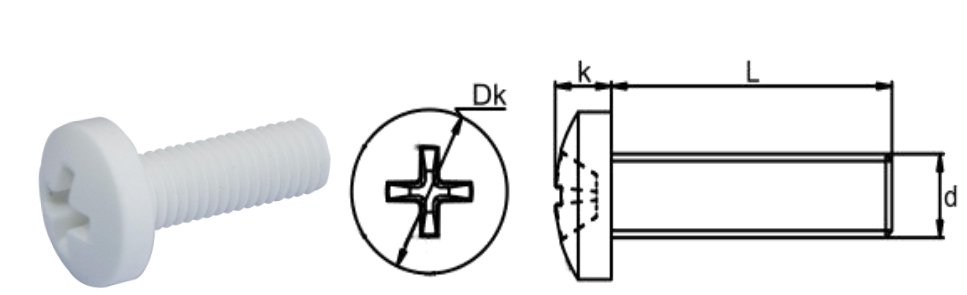

PA66 Cross pan head screw

PA66 Slotted Pan Head Screw is primarily chosen when an application requires the fundamental benefits of a polymer fastener, coupled with the wide bearing surface of a pan head and the simplicity of a slotted drive.

M Size: M2-M12

peek plastic material: Polyamide66(PA66)

product type: Pan Head Screws

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 Cross pan head screw Overview

PA66 Cross Pan Head Screw (also known as a PA66 Phillips Pan Head Screw) is one of the most widely used polymer fasteners. It combines the universal Phillips (Cross) drive for efficient assembly, the wide load distribution of the Pan Head, and the core non-metallic advantages of PA66 Nylon

Key Features

The screw’s utility is defined by its material and its drive/head combination:

- Excellent Electrical Isolation: PA66 is a reliable dielectric material, making it an essential PA66 Electronic Insulating Screw. This property is critical for separating electronic conductors and preventing short circuits.

- Corrosion Immunity: The fastener is entirely rust-proof and highly Nylon Screw Corrosion Resistant to most common solvents, weak acids, and saltwater, outperforming standard steel in harsh or humid environments.

- Load Distribution (Pan Head): The Pan Head has a wide bearing surface, which effectively distributes the clamping force, protecting soft or thin materials (like plastic housings or thin sheet metal) from damage.

- Assembly Efficiency (Cross Drive): The Phillips (Cross) drive is the most common drive system globally, offering good self-centering capability for rapid, automated, or manual assembly, making it highly efficient.

- Lightweight: As a polymer fastener, it provides a significant PA66 Screw Lightweight Advantage, crucial for portable electronics and automotive trim applications.

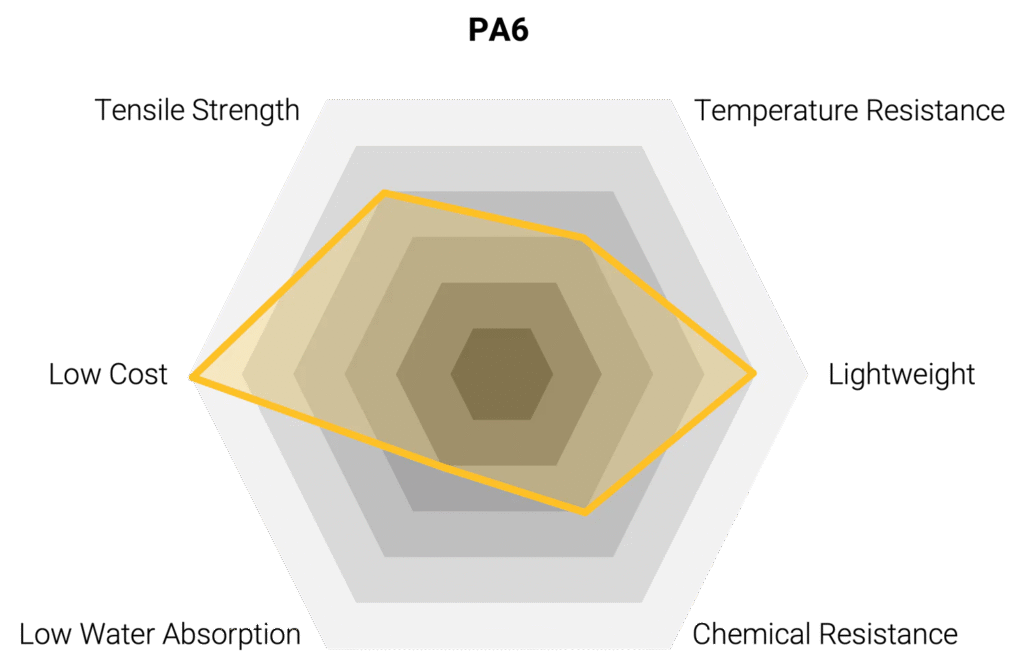

Key Polyamide Nylon (PA6) Properties

Pros and Cons Analysis

✅ Advantages (Pros)

- Electrical Isolation: Provides safe, effective separation and prevents galvanic corrosion between different metals.

- Corrosion Proof: Absolute immunity to rust and good resistance to common chemicals and solvents.

- High Assembly Speed: The Phillips (Cross) drive is universal and highly efficient for rapid, high-volume production.

- Load Distribution: Pan Head protects soft mating surfaces from damage and indentation.

- Cost-Effective: Extremely low cost due to high-volume injection molding.

❌ Disadvantages (Cons)

- Low Strength: Not suitable for high-stress or structural applications, as its tensile and shear strength are significantly lower than metal.

- Stripping and Cam-Out Risk: The combination of the relatively soft PA66 material and the design of the Phillips drive increases the risk of Nylon Screw Stripping Risk (thread failure) and Cross Recess Screw Cam-Out (driver slipping out) if the Plastic Screw Torque Specs are not precisely controlled.

- Moisture Sensitivity: PA66 is hygroscopic. PA66 Screw Moisture Absorption can cause slight swelling and reduction in mechanical properties in high-humidity environments.

- Creep Tendency: Susceptible to permanent deformation (creep) under sustained clamping pressure, which can lead to joint loosening over time.

Applications

PA66 Cross Pan Head Screw is used extensively in applications where insulation, corrosion resistance, and high-volume assembly are key priorities:

- Electronics and IT Hardware: Primarily used for securing plastic or metal covers, chassis panels, and PCBs in computers, servers, and consumer electronics. The PA66 Screw for PCB Assembly relies on the material’s insulating properties.

- Automotive Interior: Used for securing interior trim pieces, fascia panels, wire harnesses, and non-structural components where the screw must be non-conductive and corrosion-resistant (PA66 Automotive Trim Screw).

- Appliances and Consumer Goods: Utilized in high-volume production for assembly of washing machines, dryers, toys, and other goods, prioritizing low cost and corrosion resistance.

- Marine and Outdoor Assemblies: Applied in exposed environments due to its absolute immunity to saltwater and humidity.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.