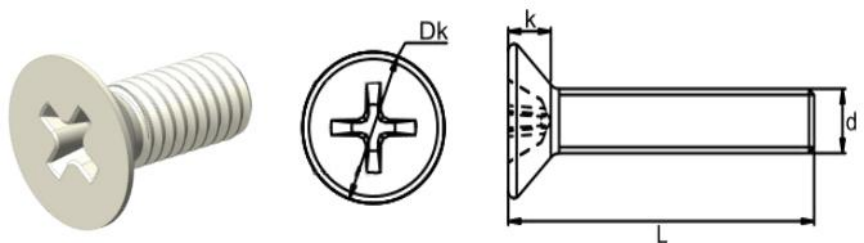

PA66 Countersunk Screws-Cross Recessed Phillips

PA66 Countersunk Screws-Cross Recessed Phillips is a staple fastener for assemblies requiring a smooth, flush surface where high structural strength is not the primary requirement.

M Size: M2-M10

peek plastic material: Polyamide66(PA66)

product type: Countersunk Screws

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 Countersunk Screws-Cross Recessed Phillips Overview

PA66 Countersunk Screws-Cross Recessed Phillips PA66 Countersunk Screws-Cross Recessed Phillips ( Slotted Flat Head Screw) is a popular polymer fastener chosen for its non-metallic properties (insulation, corrosion resistance) combined with the aesthetic and functional benefit of a flush surface finish.

Key Features

The screw’s key features stem from the combination of the Countersunk head and PA66 material:

- Flush Finish (Aesthetic and Safety): The Countersunk head geometry ensures the fastener recesses fully into the material, achieving a flush surface finish (PA66 Countersunk Screw Aesthetic). This is crucial for safety, ergonomics, and clean aesthetics.

- Excellent Electrical Isolation: PA66 is a strong dielectric, making it a reliable PA66 Electrical Insulating Screw that separates electrical components and prevents galvanic corrosion between dissimilar materials.

- Corrosion Immunity: The fastener is completely rust-proof and offers superior Nylon Screw Corrosion Resistant properties against weak acids, salts, and common solvents, ideal for PA66 Marine Applications Screw.

- Assembly Efficiency (Phillips Drive): The universally recognized Phillips (Cross Recessed) drive provides good self-centering capability, enabling fast, high-volume assembly.

- Lightweight: The polymer structure provides a significant PA66 Screw Lightweight Advantage over metal fasteners.

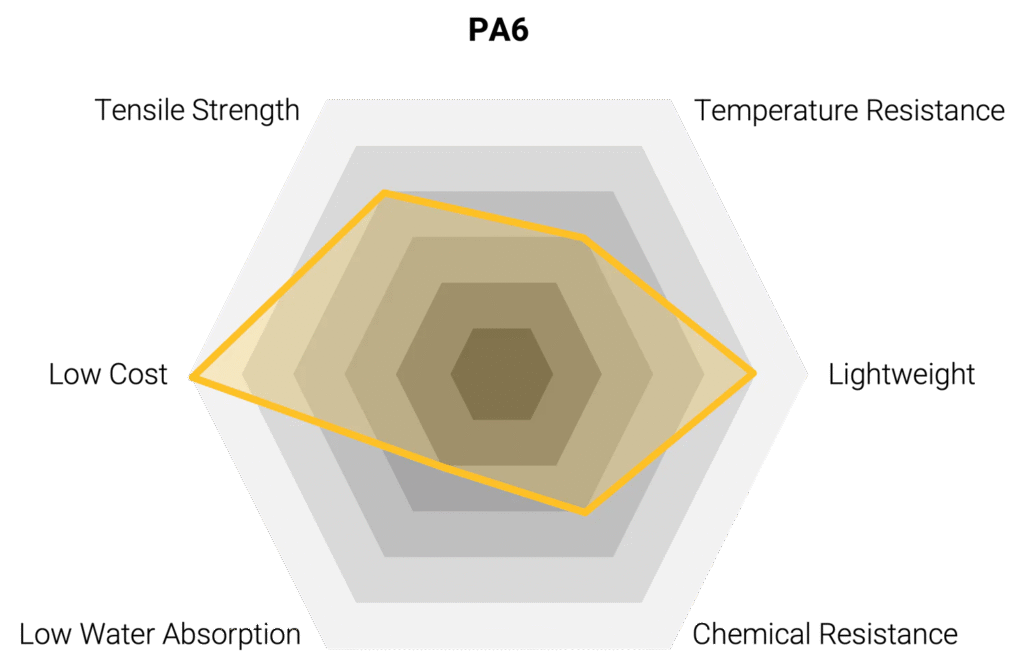

Key Polyamide Nylon (PA6) Properties

Applications

This screw is primarily used in light-to-medium load assemblies where a smooth surface and non-metallic properties are mandatory:

- Electronics and Enclosures: Widely used for securing faceplates, covers, and panels where the smooth surface is necessary for appearance or to prevent snagging. It relies on its insulating properties in these applications.

- Automotive Interior: Essential for securing interior trim, dashboard components, and door panels (PA66 Automotive Interior Fasteners), where the head must not protrude.

- Medical and Laboratory Equipment: Used in devices that require a clean, non-magnetic, and smooth surface that is easy to sterilize.

- General Assembly: Applied in furniture, displays, and consumer goods where the functional requirement is a Flush Plastic Fastener.

Advantages&Disadvantages

✅ Advantages (Pros)

- Aesthetic and Safety: Achieves a perfectly smooth, flush surface finish, preventing snags and improving appearance.

- Electrical Isolation: Provides safe, effective separation and prevents galvanic corrosion.

- Corrosion Proof: Offers absolute immunity to rust and good resistance to many common chemicals.

- Assembly Efficiency: The Phillips drive is ideal for quick, high-volume production.

- Lightweight: Contributes significantly to overall mass reduction.

❌ Disadvantages (Cons)

- High Stripping Risk (Major Failure Point): This is the screw’s greatest weakness. The combination of the weak Phillips drive and the thin, conical wall of the countersunk head makes it highly vulnerable to failure. Over-torquing almost guarantees Plastic Countersunk Head Stripping or head breakage.

- Requires Pre-Processing: Installation requires a precise countersink to be drilled into the mating material, adding a step to the assembly process to achieve a flush fit.

- Low Load Capacity: Unreinforced PA66 has low tensile and shear strength. It is not suitable for high-stress applications.

- Moisture Sensitivity: Nylon Screw Dimensional Stability can be affected by moisture absorption, leading to slight swelling and potential loss of preload over time.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.