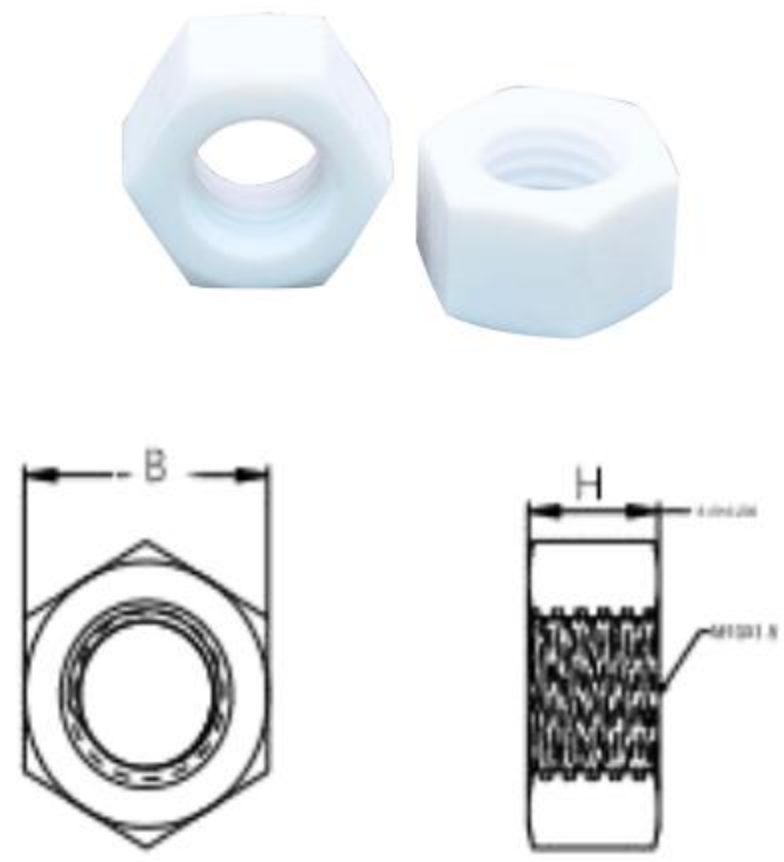

PA66 Hex nut

PA66 Hex nut are a basic polymer fastener used in conjunction with metal bolts or PA66 bolts for non-structural applications requiring electrical insulation and corrosion resistance.

M Size: M3-M30

peek plastic material: Polyamide66(PA66)

product type: Nuts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 Hex nut Overview

PA66 Hex Nut is defined by its versatile geometry, which allows easy use with standard wrenches, combined with the core properties of Nylon 66 (PA66). It serves as a lightweight, insulating, and non-corrosive alternative to metal hex nuts.

Key Features

The value of the PA66 Hex Nut lies in its non-metallic nature and structural shape:

- Electrical Isolation: PA66 provides excellent dielectric strength, positioning it as an ideal PA66 Electrical Insulating Nut. It effectively prevents galvanic corrosion and acts as an isolator in electrical assemblies.

- Corrosion Immunity: The nut is completely rust-proof and offers strong Plastic Nut Corrosion Resistance to saltwater, oils, and many industrial chemicals, making it far superior to standard carbon steel in corrosive environments.

- Lightweight and Non-Magnetic: It offers significant weight savings (PA66 Nut Lightweight Advantage) critical for aerospace, robotics, and portable devices. Being non-magnetic (PA66 Nut Non-Magnetic) is essential for sensitive equipment like MRI machines or measuring instruments.

- Structural Efficiency (Hex Design): The hexagonal shape allows for easy engagement with standard wrenches, facilitating efficient assembly and disassembly, and ensuring consistent load transfer from the wrench to the thread.

- Temperature Rating: While generally lower than metal, PA66 maintains integrity up to a reasonably high continuous service temperature (relevant to PA66 High Temperature Nut searches).

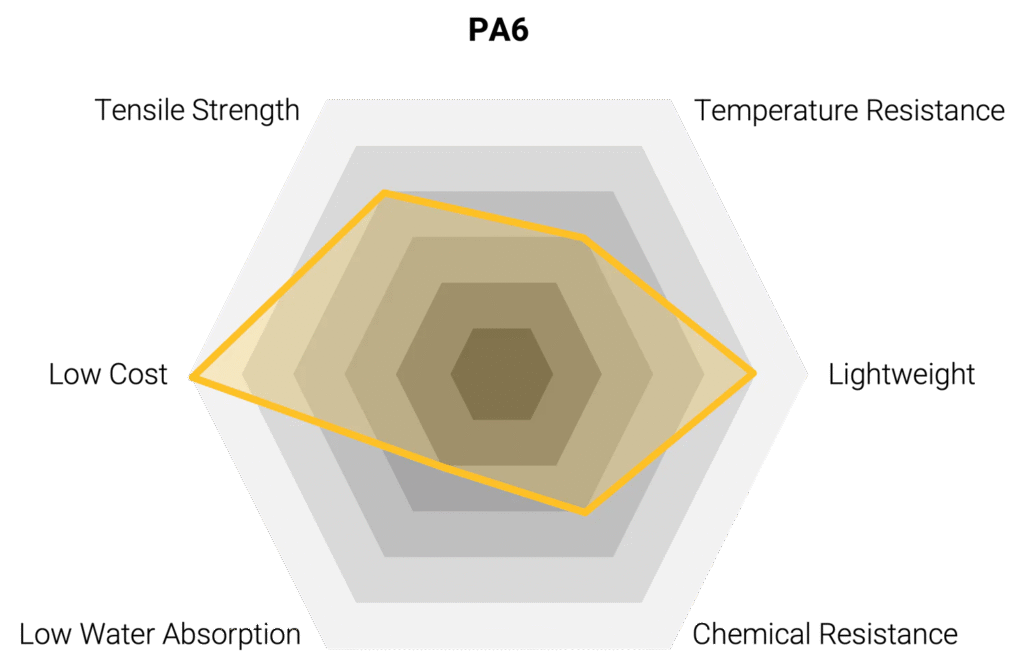

Key Polyamide Nylon (PA6) Properties

Applications

The PA66 Hex Nut is used where the non-metallic properties are mandated, and the load requirements are moderate to low:

- Electronics and IT Hardware: Used for fastening terminal blocks, circuit boards, chassis, and housing covers, relying on PA66 Fasteners for Electronics to provide necessary insulation.

- Marine and Outdoor Assemblies: Ideal for use on boats, docks, and outdoor signage where constant exposure to humidity, UV, and saltwater requires absolute Nylon Nut Marine Environment resistance.

- Chemical Processing: Used to assemble filtration systems, plumbing, and tanks where contact with corrosive fluids is unavoidable.

- Consumer Goods: Applied in appliances, toys, and small mechanisms where vibration damping (PA66 Nut Vibration Damping) and lightweight characteristics are beneficial

Pros&Cons

✅ Advantages (Pros)

- Safety and Isolation: Provides reliable electrical and thermal isolation.

- Corrosion Proof: Guarantees zero rust and superior chemical resistance.

- Lightweight: Significant contributor to weight reduction in assemblies.

- Cost-Effective: Often cheaper than specialty corrosion-resistant metals (e.g., high-grade stainless steel).

- Non-Magnetic: Suitable for sensitive magnetic fields and imaging equipment.

❌ Disadvantages (Cons)

- Low Torque and Strength: The most significant limitation is its low tensile strength and shear strength compared to metal. It requires strict adherence to Plastic Nut Torque Specs to prevent thread Nylon Nut Stripping Risk or failure.

- Creep: Under continuous, heavy loads, the material is prone to Creep Failure (permanent deformation over time), limiting its use in structural applications.

- Moisture Absorption: PA66 is hygroscopic. PA66 Nut Dimensional Stability can be affected by high humidity, potentially causing slight swelling and minor changes in mechanical properties.

- Temperature Sensitivity: Performance drops off rapidly near the maximum continuous operating temperature, unlike metal.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.