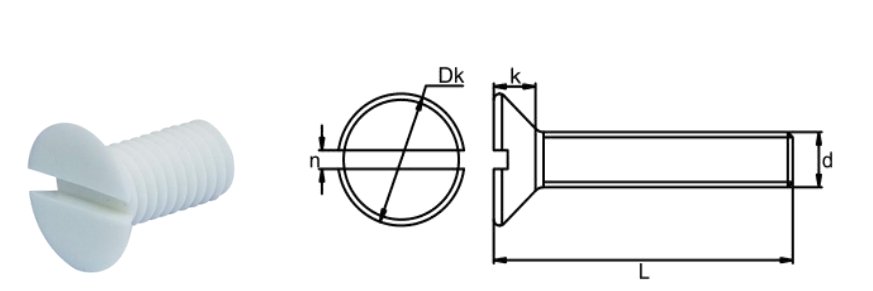

PP Slotted countersunk head screw

PP Slotted countersunk head screw has a specific gravity of 0.9, which is the lightest among plastics; it has excellent mechanical properties, good chemical stability; excellent electrical properties, and is resistant to high-frequency electrical insulation.

M Size: M2-M10

peek plastic material: PP Polypropylene

product type: Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PP Slotted countersunk head screw Overview

PP (Polypropylene) Slotted Countersunk Head Screw is an economical and highly versatile plastic screw primarily known for its exceptional chemical resistance and ability to provide a flush surface finish. The Countersunk Head (Flat Head) is designed to recess completely into the material, while the Slotted Drive allows for conventional installation.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PP) | Polypropylene. A semicrystalline thermoplastic known for its rigidity, toughness, and superior chemical resistance to a wide range of substances. | Provides a cost-effective fastener that is immune to rust, corrosion, and many aggressive chemicals. |

| Head Style (Countersunk/Flat Head) | Features a flat top surface and a tapered underside (conical). | Designed to recess into a prepared hole, allowing the head to sit flush with the surface for a smooth, clean, snag-free finish. |

| Drive Style (Slotted) | A simple single slot on the top surface. | Allows for installation using a flat-blade screwdriver; suitable for low-torque applications. |

Product Parameters

PP Slotted Countersunk Head Screws typically follow metric standards for slotted countersunk head screws, such as ISO 2009 (Slotted Countersunk Flat Head Screws).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Angle | Slot Width (N) |

| M3 | 0.5 mm | 5.6 mm | 90°C | 0.8 mm |

| M4 | 0.7 mm | 7.5 mm | 90°C | 1.0 mm |

| M5 | 0.8 mm | 9.2 mm | 90°C | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | 90°C | 1.6 mm |

| M8 | 1.25 mm | 14.5 mm | 90°C | 2.0 mm |

| M10 | 1.5 mm | 18.0 mm | 90°C | 2.5 mm |

Key Features

PP Countersunk Screws offer a crucial aesthetic and functional benefit alongside their material advantages:

Excellent Chemical Resistance: Superior resistance to a vast range of inorganic and organic chemicals, acids, and alkalis.

Flush Finish: Creates a smooth, snag-free surface, essential in high-flow fluid lines, clean areas, or components requiring easy cleaning.

Corrosion Immunity: Will not rust or cause galvanic corrosion, lasting indefinitely in wet or chemical atmospheres.

Cost-Effective: One of the most economical fasteners for this level of chemical resistance.

Non-Conductive: Provides reliable electrical insulation.

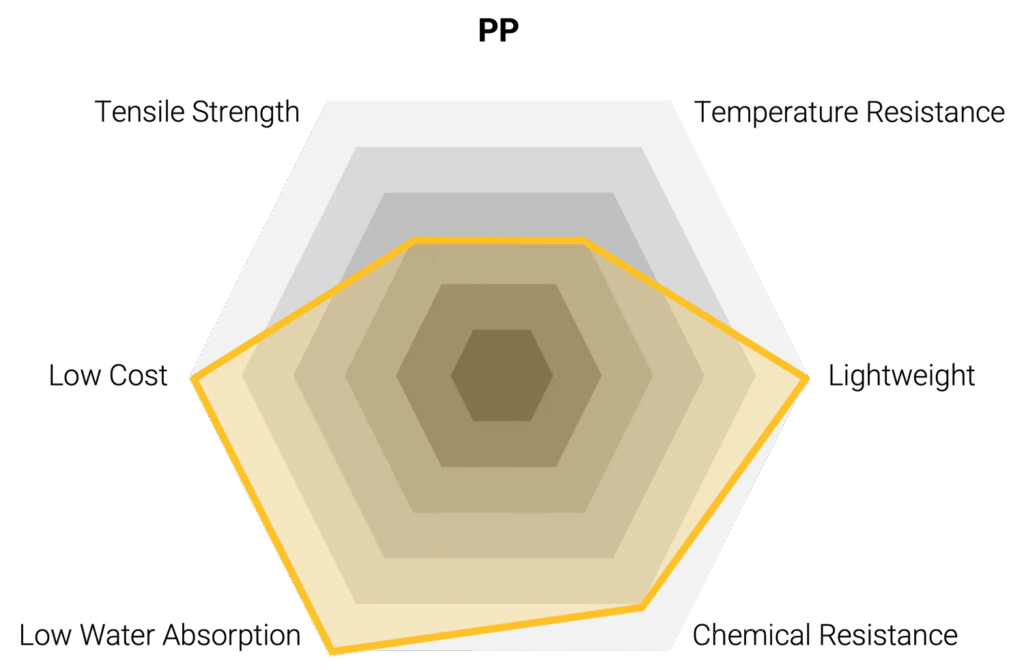

Key Polypropylene (PP) Properties

Applications

PP Slotted Countersunk Head Screws are commonly used in applications prioritizing chemical resistance, cost, and a smooth surface:

Chemical Processing: Securing smooth, internal liners or non-structural panels in tanks and piping where liquid flow must not be disrupted by protruding heads.

Water Treatment: Fastening components in water purification systems, where chemical exposure and a clean, non-snagging surface are needed.

Laboratory Equipment: Assembling non-critical fixtures, racks, and enclosures in damp or chemical lab environments.

Food and Beverage: Used on non-contact surfaces of processing equipment where sanitation and resistance to cleaning agents are important.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Aesthetics/Function | Creates a smooth, snag-free, flush surface. Superior chemical resistance. | Requires Preparation: Installation requires a precise countersunk hole, adding a manufacturing step. |

| Performance | High rigidity and cost-effectiveness. Lightweight and non-contaminating. | Low Mechanical Strength: Cannot withstand high tensile loads; threads are easily stripped if over-torqued. |

| Design | Suitable for highly corrosive environments. | Slotted Drive Limitation: Provides low torque transmission and is prone to tool slip (cam-out). |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.