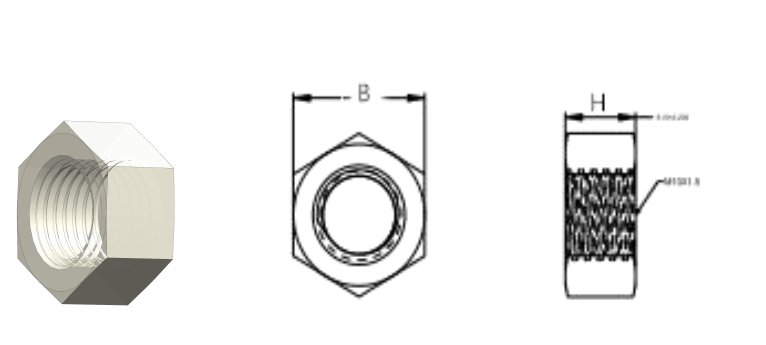

PP Hex nut

PP Hexagon nut has a specific gravity of 0.9, which is the lightest among plastics; it has excellent mechanical properties, good chemical stability; excellent electrical properties, and is resistant to high-frequency electrical insulation.

M Size: M3-M30

peek plastic material: PP Polypropylene

product type: Nuts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PP Hex nut Overview

polypropylene (PP) hexagon nut, often called a PP hex nut, is a six-sided nut made from polypropylene, a common and economical engineering plastic. Unlike stainless steel hex nuts or metal fasteners, PP hex nuts combine lightweight structure, excellent chemical resistance, and good electrical insulation

Product Parameters

PP Hexagon Nuts generally follow established metric standards for regular hexagon nuts, such as ISO 4032, ensuring compatibility with standard bolts and threaded rods.

| Nominal Size (Bolt d) | Thread Pitch (P) | Across Flats (s) | Nut Height (m) |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm |

| M5 | 0.8 mm | 8.0 mm | 4.7 mm |

| M6 | 1.0 mm | 10.0 mm | 5.2 mm |

| M8 | 1.25 mm | 13.0 mm | 6.4 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 10.0 mm |

| M16 | 2.0 mm | 24.0 mm | 13.0 mm |

Key Features

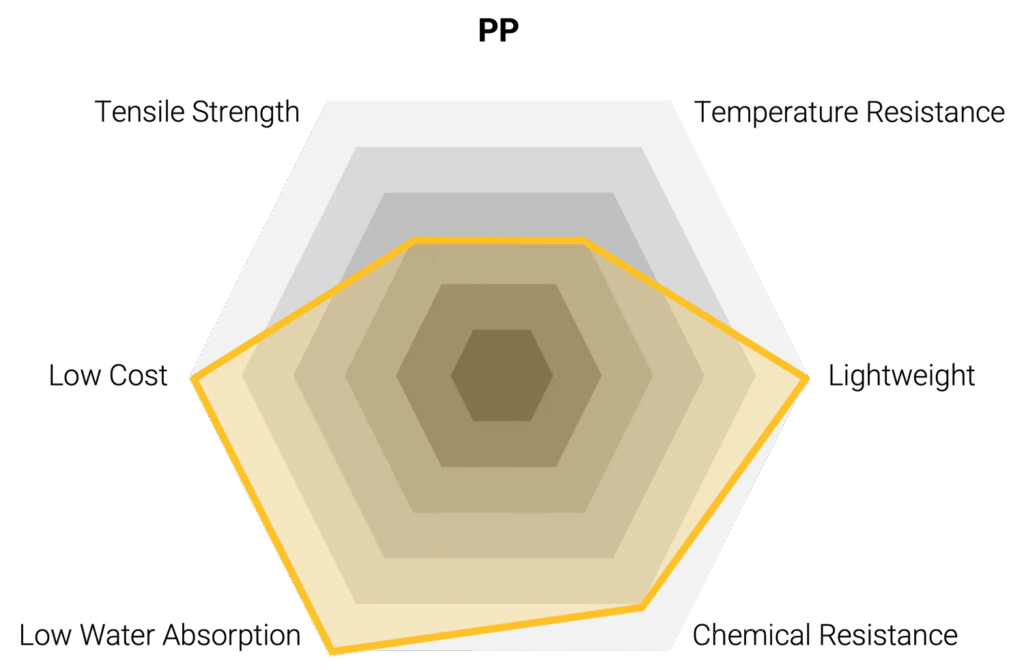

Polypropylene’s properties define the distinguishing features of the PP Hexagon Nut:

Excellent Chemical Resistance: PP is highly resistant to a broad spectrum of acids, bases, salts, and organic solvents (better than nylon hex nut in some chemical environments).

Low Density and Cost: It is one of the lightest and most economical plastic screws or fasteners available, ideal for mass production and lightweight design.

Low Water Absorption: PP has extremely low moisture absorption, giving it better dimensional stability than standard Nylon in wet environments.

Electrical Insulation: It is a reliable dielectric, effectively preventing galvanic corrosion and short circuits in any hex nut bolt assembly.

Fatigue Resistance: PP exhibits good resilience against repeated bending or flexing.

Dimensional Compliance: Manufactured to adhere to precise hex nut diameter and hex nut height standards, making it compatible with any standard hex bolt nut.

Key Polypropylene (PP) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Cost & Weight | Most Economical: Highly cost-effective for high-volume use. Extremely Lightweight. | Low Mechanical Strength: Low tensile strength and stiffness compared to metal or engineering plastics, limiting its use under high load. |

| Protection | Excellent Chemical Resistance and Moisture Resistance. Reliable Electrical Insulation. | Temperature Limit: Low maximum service temperature (approx. 100°C), unsuitable for hot environments. |

| Comparison | Better chemical stability and lower moisture absorption than nylon hex nut. Solves the lock nut vs hex nut dilemma when corrosion is the primary failure mode. | UV Degradation: Susceptible to UV light damage (embrittlement and discoloration) if not specifically UV-stabilized, unlike metal fasteners. |

| Installation | Available in standard formats (metric hex nuts and imperial sizes). | Torque Limitations: Very low installation torque limit. High compression leads to creep, making it unsuitable for use with hex lock nuts or standard torque protocols. |

Applications

PP Hexagon Nuts are widely used across consumer and industrial sectors that require moisture or chemical resistance combined with low cost.

Plumbing and Water Treatment: Used extensively in pipe assemblies, valves, and fluid handling where fasteners are exposed to water, salt, and common cleaning agents.

Chemical and Laboratory Equipment: Employed in non-critical lab equipment, ventilation systems, and tanks handling general chemicals.

Consumer Goods and Appliances: Used in refrigerators, washing machines, and outdoor furniture due to its low cost and moisture resistance.

Outdoor and Marine Environments: Provides reliable, rust-free fastening for decking, fencing, and boat fittings where stainless steel hex nuts may be overkill.

Fastener Isolation: Used as a non-conductive spacer to prevent contact between dissimilar metals, thereby stopping galvanic corrosion.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.