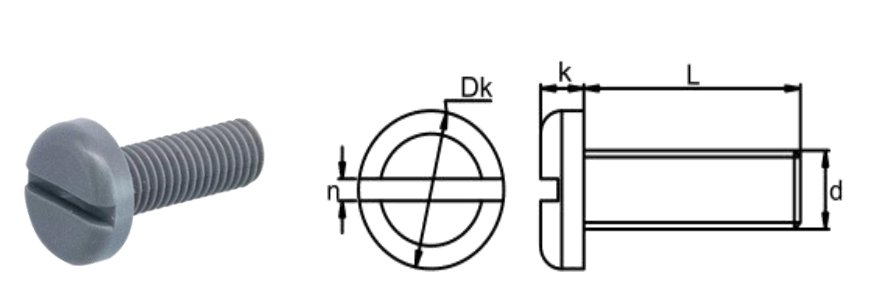

PVC Slotted pan head screw

PVC Slotted pan head screw has excellent acid, alkali and solvent resistance; hard texture, high mechanical strength; good insulation performance; poor thermal stability: chlorine and other harmful substances will be produced when burned.

M Size: M2-M10

peek plastic material: Polyvinylchloride(PVC )

product type: Pan head bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVC Slotted pan head screw Overview

PVC (Polyvinyl Chloride) Slotted Pan Head Screw is a widely used, economical plastic screw primarily valued for its excellent corrosion resistance against most chemicals at ambient temperatures. The Pan Head design provides a generous bearing surface for effective clamping, while the Slotted Drive allows for simple, conventional installation.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PVC) | Polyvinyl Chloride. A cost-effective thermoplastic known for its rigidity and chemical resistance to most acids and alkalis. | Provides a fastener that is immune to rust and galvanic corrosion at a lower cost than high-performance polymers. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for strong clamping and resistance to pull-through. |

Product Parameters

PVC Slotted Pan Head Screws typically follow metric standards for slotted pan head screws, such as ISO 1580 or similar industry specifications.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Slot Width (N) |

| M3 | 0.5 mm | 6.0 mm | 2.0 mm | 0.8 mm |

| M4 | 0.7 mm | 8.0 mm | 2.6 mm | 1.0 mm |

| M5 | 0.8 mm | 9.5 mm | 3.3 mm | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | 3.9 mm | 1.6 mm |

| M8 | 1.25 mm | 14.0 mm | 5.2 mm | 2.0 mm |

| M10 | 1.5 mm | 17.0 mm | 6.0 mm | 2.5 mm |

Key Features

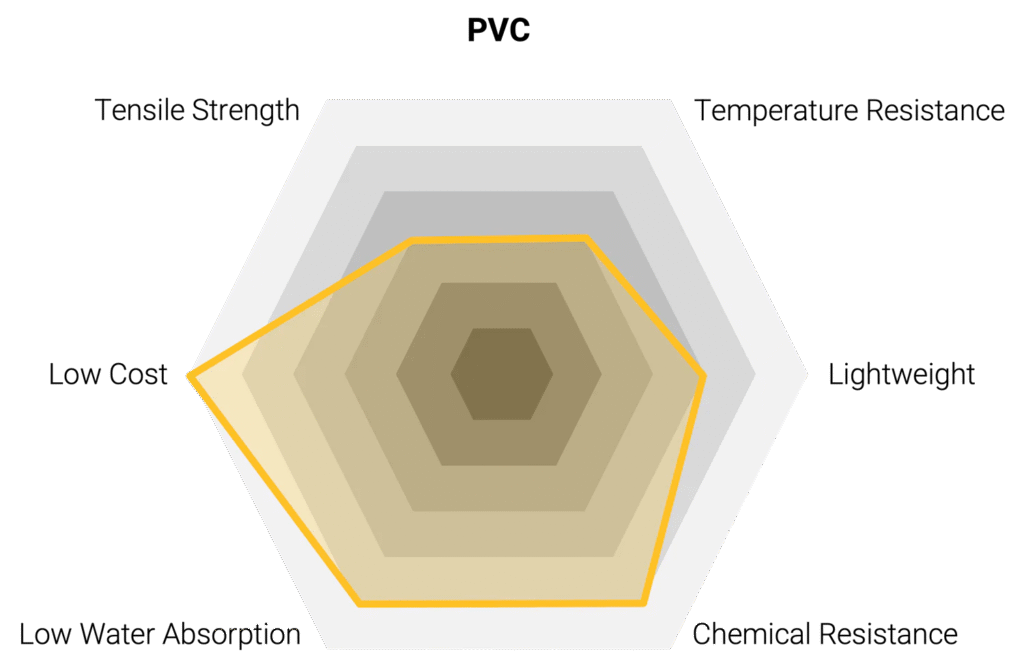

PVC fasteners are defined by their combination of chemical resistance and low cost:

Excellent Chemical Resistance: Highly stable against most mineral acids and bases at room temperature, making it ideal for chemical plumbing.

Corrosion Immunity: Will not rust or cause galvanic corrosion, lasting indefinitely in wet or corrosive atmospheres.

Low Cost: One of the most economical corrosion-resistant fasteners available, suitable for large projects.

Good Rigidity: Provides sufficient stiffness for low-load fastening tasks.

Wide Bearing Surface: The Pan Head offers good pull-through resistance.

Key Polyvinyl Chloride (PVC) Properties

Applications

PVC Slotted Pan Head Screws are commonly used in applications prioritizing chemical resistance and budget over high mechanical strength:

Water Treatment and Plumbing: Securing components, strainers, and access covers in water purification equipment, pool systems, and non-pressurized lines.

Chemical Containment: Fastening lightweight guards, labels, and covers on tanks and pipe systems handling ambient-temperature acids and bases.

Laboratory Equipment: Assembling non-critical fixtures, racks, and enclosures in damp or chemical lab environments.

Marine and Outdoor: Securing non-structural components exposed to humidity, rain, and saltwater spray.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Excellent corrosion resistance against common chemicals. Highly economical. | Low Mechanical Strength: Cannot withstand high tensile or shear loads; easily stripped. |

| Material | Lightweight and non-conductive. Widely available. | Low Temperature Limit: Maximum continuous service temperature is typically low (60°C). |

| Design | Pan Head provides superior load distribution. | Slotted Drive Limitation: Provides low torque transmission and is prone to cam-out. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.