PVC Flat washer

PVC Flat washer are non-metallic gaskets or bearing washers that provide insulation, corrosion resistance, and sealing.

M Size: M3-M30

peek plastic material: Polyvinylchloride(PVC )

product type: Washers

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVC Flat washer Overview

PVC Flat Washer is a type of non-metallic spacer or bearing surface used primarily where a standard metal washer (like a stainless flat washer) would corrode or conduct electricity. Made from Polyvinyl Chloride (Polyvinyl chloride washer), it is an economical choice that combines good chemical resistance with inherent electrical insulation.

common metric standards like PVC M6 washer and PVC M8 washer, to imperial sizes like 1/4 inch PVC flat washer.

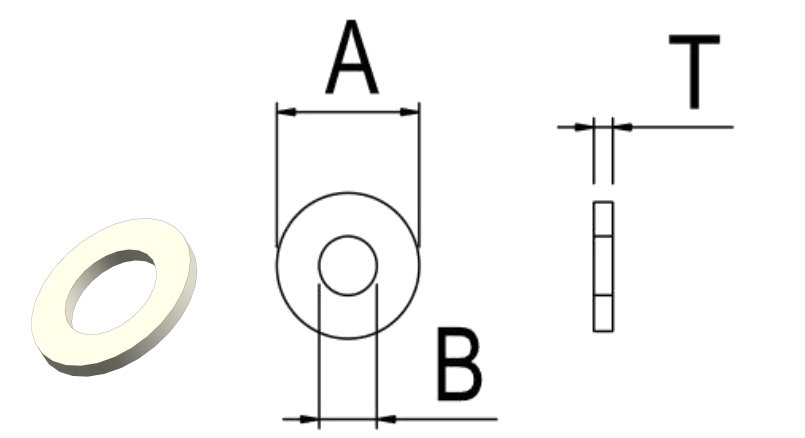

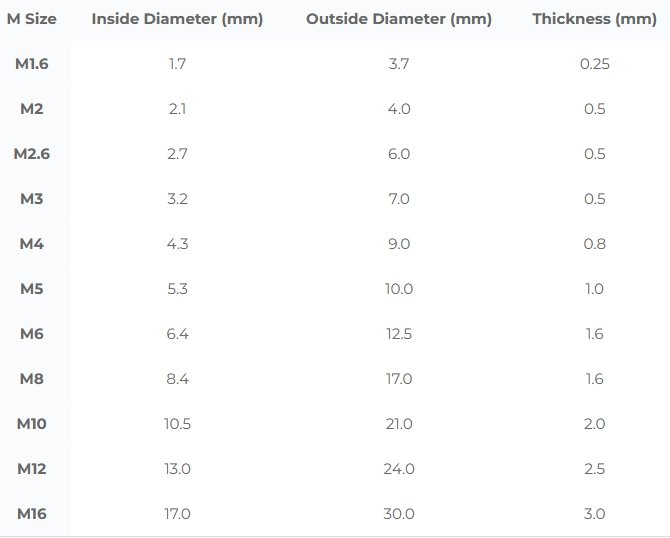

Product Parameters

PVC Flat washer flat washer dimensions chart:

Key Features

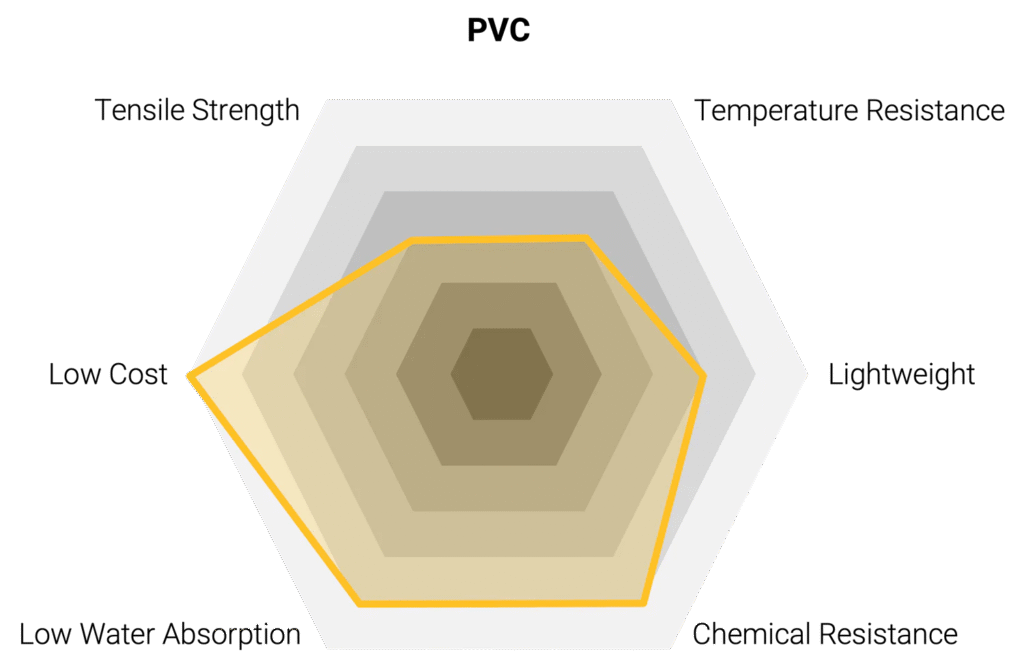

The advantages of the PVC flat washer are driven by the inherent properties of the PVC polymer, setting it apart from metal or nylon options (flat washer nylon).

Corrosion Resistance: PVC is highly resistant to a broad range of acids, alkalis, salts, and oils (Washer for chemical environment). This is a primary reason for choosing it over metal, even stainless flat washer variants, in corrosive atmospheres.

Electrical Insulation: PVC is a natural insulator, making it excellent for creating a dielectric barrier between fasteners and electronic components (PVC insulation washer).

Waterproof and Sealing: Due to its structure, PVC does not absorb water and can be used for light sealing applications (Plastic sealing washers). Flexible PVC washers offer better sealing properties.

Cost-Effective: Polyvinyl chloride washer production is generally inexpensive, making it a cost-effective choice for high-volume needs (Buy PVC washers bulk).

Hardness: PVC washers can vary in hardness (Shore hardness of PVC washer), offering options between rigid spacers and semi-flexible sealing washers.

Key Polyvinyl Chloride (PVC) Properties

Applications

The unique features of the PVC flat washer dictate specialized applications where metal, nylon, or rubber are unsuitable.

Plumbing and Waterworks: Crucial for creating seals and preventing electrolysis between dissimilar metals in pipe joints (PVC washer for pipe / PVC washer for plumbing).

Electrical and Electronics: Used as a non-conductive spacer to insulate circuits from metal chassis or to prevent galvanic corrosion where two different metals meet.

Chemical Processing: Employed in tanks, piping, and equipment exposed to caustic or acidic fluids where a Corrosion resistant PVC washer is essential.

Outdoor Signage and Fixtures: Used under screws or bolts to protect painted surfaces and provide a moisture barrier, often specified as White PVC flat washers for aesthetic reasons.

Assembly and Spacing: Used as a PVC spacer washer or PVC flat spacer in light-duty assemblies to adjust height or distribute load.

Advantages

Corrosion and Chemical Resistance: PVC’s resistance to a wide range of chemicals makes it very durable in aggressive or moist environments.

Electrical Insulation: Being non-conductive, PVC washers safely isolate fasteners in electrical assemblies.

Lightweight: Much lighter than metal washers, which is beneficial for portable or weight-sensitive applications.

Cost-Effective: PVC is inexpensive to produce, making these washers an economical choice.

Non-Galvanic Behavior: PVC does not cause galvanic corrosion when contacting dissimilar metals.

Design Flexibility: Wide range of sizes, diameters, and thicknesses; plus the possibility of customizing inner diameter.

Sealing Capability: Can serve as a spacer or gasket, depending on hardness and formulation.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.