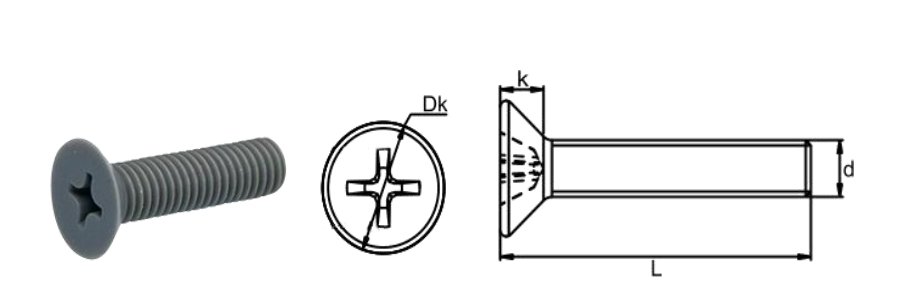

CPVC Cross counter sunk head screw

CPVC Cross counter sunk head screw material is heat resistant, resistant to corrosion from acids, alkalis, salts, oxidants, etc. The maximum continuous use temperature can reach 90-100°C

M Size: M3-M10

peek plastic material: chlorinatedpolyvinylchloride (CPVC)

product type: Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

CPVC Cross counter sunk head screw Overview

The CPVC (Chlorinated Polyvinyl Chloride) cross countersunk head bolt represents a specialized class of plastic screws engineered for performance in chemically aggressive and high-temperature environments. This fastener is distinguished by its tapered head, which allows it to sit perfectly flush with the mating surface, providing a smooth, snag-free finish while maintaining excellent resistance against corrosion.

Product Parameters

CPVC countersunk bolt dimensions adhere to standard metric (ISO) and imperial sizing conventions, similar to metal countersunk bolts and nuts. Precision sizing is available, often including common specifications like countersunk m4 bolts and 3/8 countersunk bolt.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) |

| M3 | #4 | 6.0 mm / 0.24 in |

| M4 | #6 | 8.0 mm / 0.31 in |

| M6 | 1/4″ | 12.0 mm / 0.47 in |

| M10 | 3/8″ (3 8 countersunk bolt) | 18.0 mm / 0.71 in |

Key Features

The primary reasons engineers choose CPVC over metal screws or even other plastic screws are:

Chemical Superiority: Provides resistance to a broader spectrum of acids, bases, salts, and alcohols than many countersunk stainless bolts.

Elevated Temperature Resistance: Maintains structural integrity and pressure ratings at temperatures higher than standard PVC.

Non-Conductive: Excellent electrical insulation properties, eliminating the risk of shorts or grounding issues in sensitive electronics.

Purity: Non-leaching and non-contaminating, making it safe for fluid-critical environments.

Advantages and Disadvantages (Pros and Cons)

The choice often balances CPVC’s unique environmental resistance against the superior mechanical strength of metal.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Mechanical Performance | Flush Design: The countersunk geometry provides an aesthetic and safe finish. Vibration Damping due to material elasticity. | Lower Strength: Significantly lower tensile and shear strength than steel countersunk bolts. |

| Environmental Performance | Ultimate Corrosion Resistance: Immune to rust and galvanic corrosion. High Purity & Non-Magnetic. | Temperature Limits: While better than PVC, it cannot withstand the continuous high temperatures tolerated by high-end polymers or metal. |

| Installation | Compatible with standard cross-drive tools (phillips head bolt). | Brittle Risk: Susceptible to damage from excessive installation torque or extreme cold. |

Applications

CPVC Cross Countersunk Head Screw is crucial in industries demanding cleanliness, precision, and chemical inertia:

Semiconductor Manufacturing: Securing cleanroom equipment and wet-bench assemblies where fluid purity is paramount.

Chemical and Fluid Handling: Fastening components in filtration systems, processing tanks, and corrosive exhaust systems.

Electrical & Telecommunications: Used for mounting components where insulation is required, such as within junction boxes or circuit board enclosures, often requiring phillips head bolts for secure installation.

Marine and Outdoor Construction: Provides a truly non-corrosive alternative to countersunk bolts in salt-spray and high-humidity environments.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.