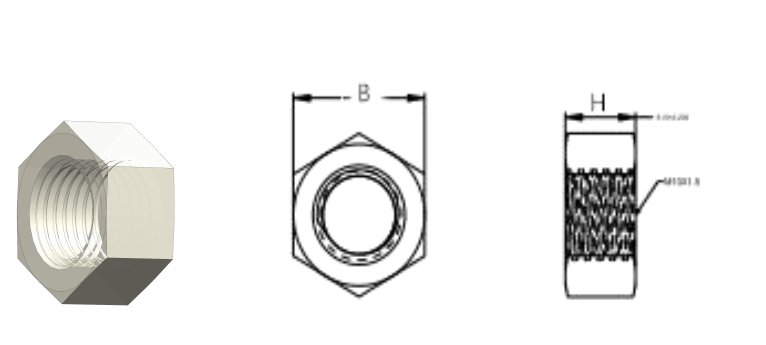

CPVC Hexagon nut

CPVC Hexagon nut material is heat resistant, resistant to corrosion from acids, alkalis, salts, oxidants, etc. The maximum continuous use temperature can reach 90-100°C

M Size: M3-M30

peek plastic material: chlorinatedpolyvinylchloride (CPVC)

product type: Nuts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

CPVC Hexagon Nut Overview

CPVC (Chlorinated Polyvinyl Chloride) Hexagon Nut is a corrosion-resistant plastic nut widely used in fluid handling, chemical processing, and water treatment systems. It is chosen for its superior chemical stability and higher temperature rating compared to standard PVC, while providing a cost-effective, non-corrosive alternative to metal nuts.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (CPVC) | Chlorinated Polyvinyl Chloride. A vinyl polymer known for its excellent resistance to a wide range of acids, alkalis, and salts. | Ensures the assembled joint is immune to rust, corrosion, and galvanic degradation. |

| Design (Hexagon Nut) | Standard six-sided external shape. | Allows for easy tightening and high torque transfer using common wrenches (spanners), providing maximum clamping force for a CPVC component. |

| Function | Used in conjunction with CPVC Hexagon Head Bolts or threaded rods. | Provides the necessary clamping force to secure components together, forming a chemically inert joint. |

Product Parameters

CPVC Hexagon Nuts typically follow international metric standards for regular nuts, such as ISO 4032, ensuring compatibility with standard bolts and tools.

| Nominal Size (Bolt d) | Thread Pitch (P) | Across Flats (s) | Nut Height (m) |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm |

| M5 | 0.8 mm | 8.0 mm | 4.7 mm |

| M6 | 1.0 mm | 10.0 mm | 5.2 mm |

| M8 | 1.25 mm | 13.0 mm | 6.4 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 10.0 mm |

| M16 | 2.0 mm | 24.0 mm | 13.0 mm |

Key Features

CPVC Hexagon Nuts are chosen for their superior performance in corrosive, moderately high-temperature environments:

Excellent Chemical Resistance: Highly stable against most mineral acids, bases, and salts, which makes them ideal for industrial drainage and chemical storage.

Good Thermal Tolerance: Suitable for service temperatures that exceed the limits of standard PVC (often up to $90^\circ \text{C}$).

Corrosion & Galvanic Immunity: Eliminates the risk of fastener failure due to chemical attack or interaction with dissimilar metals.

Non-Conductive: Provides reliable electrical insulation.

Cost-Effective: Offers a much lower cost than high-performance polymers (like PFA or PVDF) while delivering adequate chemical resistance.

Applications

- Automotive parts: engine covers, fans, gears

- Mechanical parts: bearings, gears, pulleys.

- Electronic and electronic components: switches, terminal blocks.

- Consumer goods: tool handles, sports equipment.

Advantages VS Disadvantage

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Excellent Chemical Resistance and reliable performance up to $90^\circ \text{C}$. Zero corrosion. | Low Mechanical Strength: Cannot withstand the high torque or tensile loads of metal nuts. |

| Material | Cost-Effective solution for corrosive environments. Lightweight and non-contaminating. | Torque Limitation: Easily over-tightened, leading to thread stripping or stress cracking of the plastic. |

| Design | Hexagon shape allows for maximum clamping force achievable with CPVC. | Creep: May exhibit minor creep (deformation) under sustained load, potentially requiring initial retightening. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.