PC Slotted knurled screw

PC Slotted knurled screw has strong impact resistance, strong fatigue resistance, good heat aging resistance, excellent insulation performance, resistance to weak acids and weak alkalis; and is self-extinguishing.

M Size: M3-M8

peek plastic material: PC Polycarbonate

product type: Pan head bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PC Slotted knurled screw Overview

PC (Polycarbonate) Slotted Knurled Screw (or PC Thumb Screw) is a specialty plastic fastener prized for its high impact resistance, transparency, and ergonomic design that allows for tool-free manual adjustment. It combines the strength of polycarbonate with a knurled head for easy grip, and a slotted recess for optional tool tightening.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PC) | Polycarbonate. A high-impact, transparent engineering thermoplastic with good dimensional stability. | Ensures the screw is highly durable, resistant to shock, and often used where visual clarity is important. |

| Head Style (Knurled) | Features vertical or diagonal ridges around the circumference, enabling easy finger-tightening and adjustment. | Allows for quick, tool-free assembly, access, or frequent repositioning of components. |

| Drive Style (Slotted) | Includes a single slot on the top surface. | Provides an optional means for tool-based final securing or difficult removal using a flat-blade screwdriver. |

| Application | Low-stress fastening and quick-release access in instruments and clear enclosures. | Ideal for applications needing secure locking that must be easily adjusted by hand. |

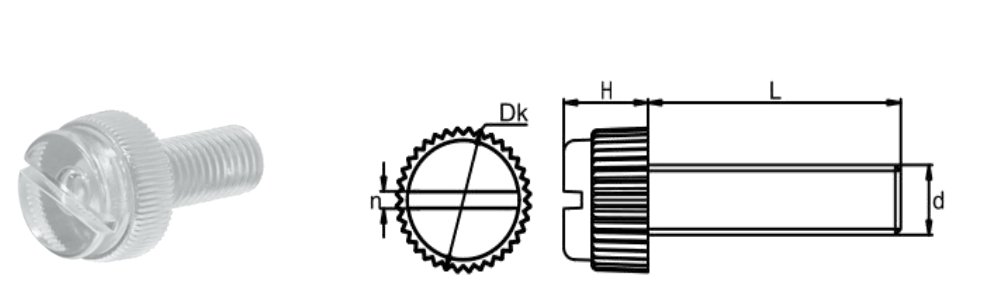

Product Parameters

Knurled screws are application-specific, and the head dimensions are ergonomic rather than strictly standardized by ISO/DIN. The thread body follows standard metric conventions, but the head size is proportional to the diameter for comfortable manual use.

Below are representative dimensions for common PC Slotted Knurled Screws:

| Nominal Diameter (d) | Thread Pitch (P) | **Typical Head Diameter (D) ** | **Typical Head Height (K) ** | Common Lengths (L) |

| M3 | 0.5 mm | 8.0 mm | 6.0 mm | 6 mm to 20 mm |

| M4 | 0.7 mm | 10.0 mm | 7.0 mm | 8 mm to 30 mm |

| M5 | 0.8 mm | 12.0 mm | 8.0 mm | 10 mm to 40 mm |

| M6 | 1.0 mm | 14.0 mm | 9.0 mm | 12 mm to 50 mm |

Key Features

The PC Knurled Screw leverages the material’s best attributes for its specialized function:

High Impact Resistance: Extremely tough and less likely to chip or crack than other plastics, even with manual handling and repeated use.

Tool-Free Operation: The knurled head allows for rapid, comfortable, manual adjustment and secure finger-tightening.

Optical Clarity: Naturally transparent, making it ideal for use in lighting, clear enclosures, or aesthetically sensitive assemblies.

Electrical Insulation: Provides superior dielectric properties, crucial for electrical and electronic assemblies.

Corrosion Immunity: Will not rust or corrode, suitable for laboratory and clean environments.

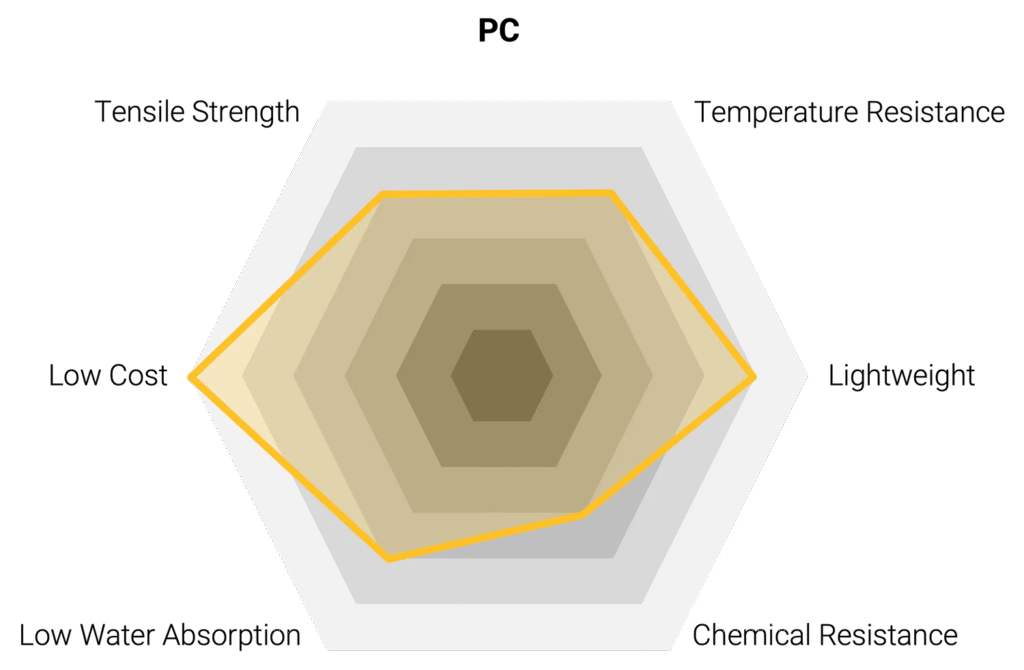

Key Polycarbonate (PC) Properties

Applications

PC Slotted Knurled Screws are essential in environments requiring quick access, adjustment, and electrical safety:

Electronics and Computer Casings: Securing quick-release access panels, battery covers, and expansion card brackets where frequent manual access is necessary.

Laboratory Equipment: Used as adjustable stops, mounts, or clamps on instrumentation and optical setups.

Display and Signage: Securing clear acrylic or plastic panels to fixtures, allowing for easy removal of the panel for cleaning or content change.

Lighting Fixtures: Fastening diffusers or lenses where a durable, non-conductive, and easy-to-remove screw is needed.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Usability | Fastest adjustment/removal due to tool-free operation. High impact resistance reduces breakage. | Low Clamping Force: Designed for low torque; cannot secure structural or high-load joints. |

| Material | Aesthetically pleasing (clear); good temperature stability for electronics. | Chemical Sensitivity: Prone to stress cracking when exposed to strong solvents or alkalis. |

| Environmental | Lightweight, non-conductive, and immune to rust. | Poor UV Resistance: Can yellow and degrade if exposed to long-term direct sunlight. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.