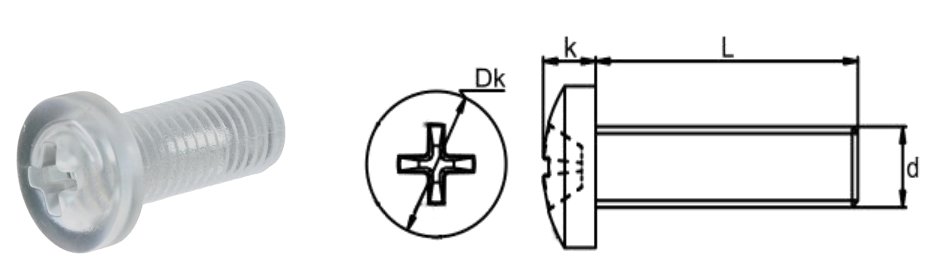

PC Cross pan head screw

PC Cross pan head screw has strong impact resistance, strong fatigue resistance, good heat aging resistance, excellent insulation performance, resistance to weak acids and weak alkalis; and is self-extinguishing.

M Size: M2-M12

peek plastic material: PC Polycarbonate

product type: Pan head bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PC Cross pan head screw Overview

PC (Polycarbonate) Cross Pan Head Screw is a high-impact plastic screw valued for its exceptional toughness, transparency, and superior electrical insulating properties. The Pan Head design provides a wide clamping surface, while the Cross (Phillips) drive ensures fast, standard tool installation.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PC) | Polycarbonate. A high-performance amorphous polymer known for its extreme toughness, impact resistance, and high light transmission. | Provides strong mechanical properties and resistance to breakage, often used where screws are visible. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for strong clamping and resistance to pull-through. |

Product Parameters

PC Cross Pan Head Screws adhere to established metric standards for cross-recess pan head screws, such as ISO 7045 (or equivalents like DIN 7985).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Cross Recess Size (PH) |

| M2 | 0.4 mm | 4.0 mm | 1.3 mm | PH1 |

| M2.5 | 0.45 mm | 5.0 mm | 1.6 mm | PH1 |

| M3 | 0.5 mm | 6.0 mm | 2.0 mm | PH1 |

| M4 | 0.7 mm | 8.0 mm | 2.6 mm | PH2 |

| M5 | 0.8 mm | 9.5 mm | 3.3 mm | PH2 |

| M6 | 1.0 mm | 10.5 mm | 3.9 mm | PH3 |

Key Features

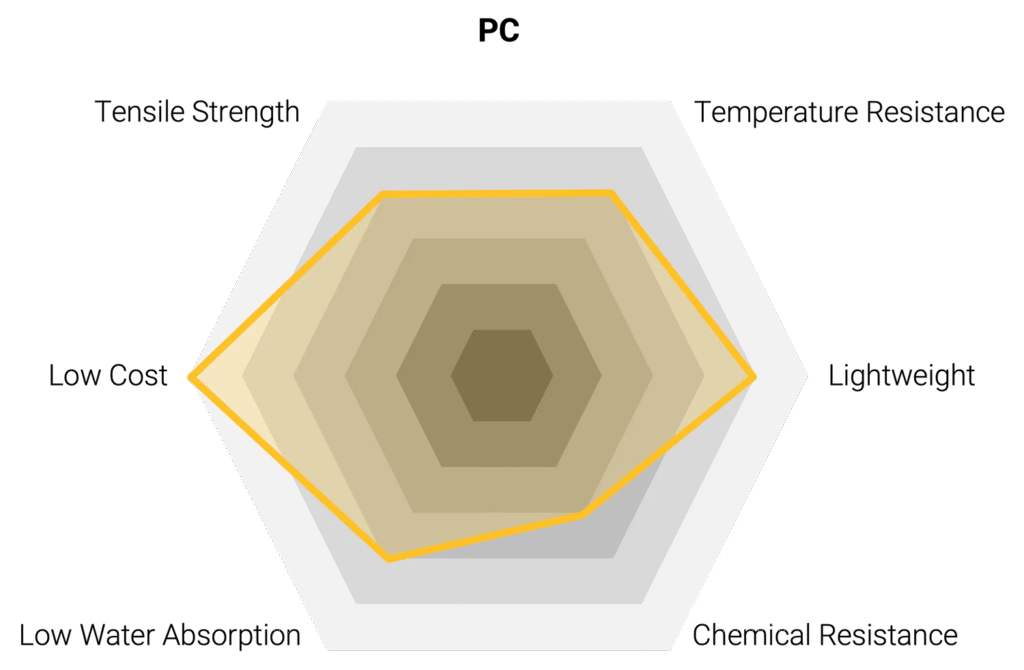

Polycarbonate fasteners are prized for a combination of toughness and clarity:

Exceptional Impact Resistance: Highly resistant to shattering or cracking, even under sharp impact or shock loads.

Good Temperature Stability: Maintains stability up to approximately $115^\circ \text{C}$, suitable for internal electronic components.

Optical Clarity: Naturally transparent, making it ideal for clear covers, lenses, or lighting fixtures.

Electrical Insulation: Provides superior dielectric properties, crucial for sensitive electronics.

Corrosion Immunity: Immune to rust and galvanic corrosion

Key Polycarbonate (PC) Properties

Advantages and Disadvantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Superior toughness and impact resistance. Excellent electrical insulation. Aesthetically pleasing (clear). | Chemical Sensitivity: Attacked by strong solvents, alkalis, and aromatic hydrocarbons, leading to stress cracking. |

| Design | Pan Head provides a wide bearing surface for secure clamping. Cross drive enables quick assembly. | Low Chemical Resistance limits use in industrial fluid or cleaning environments. |

| Environmental | Lightweight and corrosion-free. | Poor UV Resistance: Prone to yellowing and embrittlement if exposed to long-term sunlight. |

Applications

PC Cross Pan Head Screws are commonly used where clarity, strength, and electrical safety are required:

Electronics and Computers: Securing clear access panels, housing covers, and mounting components onto motherboards, leveraging its non-conductivity and impact resistance.

Lighting Fixtures: Fastening lenses, diffusers, and housings for LED lighting, where clarity and heat resistance are necessary.

Medical Devices: Used in non-critical components where visual clarity and non-magnetic fastening are beneficial.

Display and Signage: Securing clear panels on commercial displays, protective shields, or retail fixtures.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.