PA66 GF30 Hex head Bolts

PA66 GF30 Hex head Bolts (30% Glass Fiber Reinforced PA66 Hex Head Bolts) are fasteners reinforced with 30% glass fiber in a standard PA66 nylon base material.

M Size: M3-M8

peek plastic material: Polyamide66(PA66 GF30 )

product type: Hex Bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 GF30 Hex head Bolts Overview

PA66 GF30 Hex Head Bolts (30% Glass Fiber reinforced PA66 Hex Head Bolts) are fasteners enhanced by incorporating 30% Glass Fiber into the standard PA66 nylon base material.PA66 material is produced through the condensation polymerization of hexamethylenediamine and adipic acid, and is known for its high crystallinity. It belongs to the category of Nylon Screws and Plastic Screws.

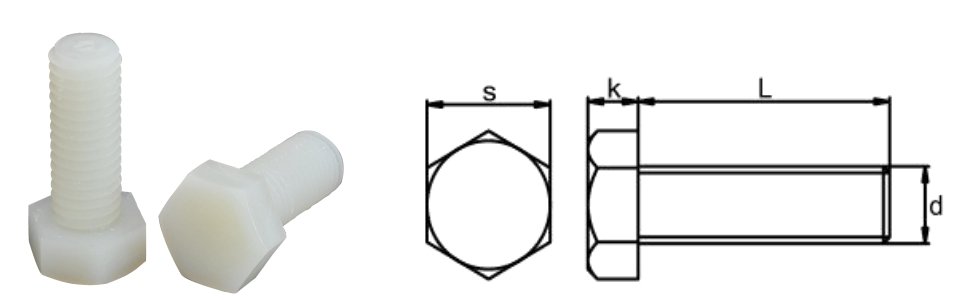

Product Parameters

PA66 GF30 Hex Head Bolts typically adhere to established metric standards for hexagon head bolts, such as ISO 4014 (partially threaded) or ISO 4017 (fully threaded).

| Nominal Diameter (d) | Thread Pitch (P) | Across Flats (s) | Head Height (k) |

| M5 | 0.8 mm | 8.0 mm | 3.5 mm |

| M6 | 1.0 mm | 10.0 mm | 4.0 mm |

| M8 | 1.25 mm | 13.0 mm | 5.3 mm |

| M10 | 1.5 mm | 16.0 mm | 6.4 mm |

| M12 | 1.75 mm | 18.0 mm | 7.5 mm |

| M16 | 2.0 mm | 24.0 mm | 10.0 mm |

Key Features

- Mechanical Performance Leap (Strength and Stiffness): The addition of 30% glass fiber significantly boosts the material’s strength (PA66 GF30) and stiffness (tensile strength can exceed 180 MPa), dramatically improving the bolt’s load-bearing capacity and resistance to deformation.

- Thermal Stability: It increases the material’s heat deflection temperature and continuous service temperature (relevant to searches for PA66 GF30 ), allowing it to withstand higher short-term or long-term operating temperatures than standard PA66.

- Dimensional Stability: The glass fiber effectively suppresses nylon’s inherent hygroscopicity (moisture absorption) and thermal expansion, enhancing the component’s dimensional stability and creep resistance (PA66 GF30 Creep Resistance).

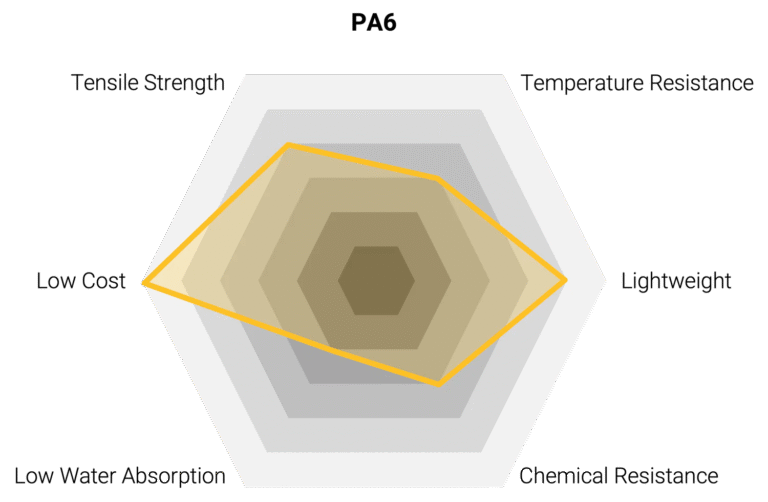

Key Polyamide Nylon (PA6) Properties

Pros and Cons Analysis

✅ Advantages (Pros)

- High Strength and Stiffness: Significantly improves the bolt’s load-bearing capacity and fatigue resistance, bringing its performance closer to that of metal, and enhancing its torque tolerance.

- Heat Resistance and Stability: Increases the heat deflection temperature and provides excellent dimensional stability.

- Lightweight: Retains nylon’s low-density advantage, which is crucial for lightweighting in the automotive and aerospace sectors.

- Chemical and Insulation: Inherits PA66’s excellent corrosion resistance and electrical insulation properties.

❌ Disadvantages (Cons)

- Increased Brittleness (Reduced Toughness): While glass fiber enhances strength, it also reduces the material’s toughness, leading to lower impact resistance and elongation, making it more prone to being brittle (PA66 GF30 bolts are fragile.).

- Higher Mold Wear: Glass fiber causes greater abrasion to injection molds, increasing production costs.

- Moisture Absorption (Still Exists): Although glass fiber mitigates it, the PA66 base material retains some moisture absorption (PA66 GF30 moisture absorption effect), meaning its long-term stability is inferior to materials like PEEK.

- Surface Quality: Glass fiber can sometimes lead to a “fiber floating” phenomenon on the product surface, affecting the aesthetics.

Applications

PA66 GF30 bolts are utilized in critical areas requiring a combination of lightweight properties, high strength, and heat resistance, thus enabling the substitution of certain metal fasteners (PA66 GF30 Alternative Metal):

- Automotive and New Energy (EV): This is the largest application market. They are used in under-the-hood components (such as intake manifolds and brackets), as well as in EV battery packs, thermal management systems, and high-voltage electrical connectors, fully leveraging their lightweight nature, insulation, and high-temperature resistance (PA66 GF30 Automotive Fasteners, PA66 GF30 EV Fasteners).

- Electronics and Electrical: Used in applications that simultaneously require mechanical stress endurance and high insulation (such as high-power switches, circuit breakers, and precision connectors).

- Industrial Equipment: Utilized in pumps, valves, and piping connections within chemical fluid delivery systems due to their high stiffness and chemical corrosion resistance (PA66 GF30).

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.