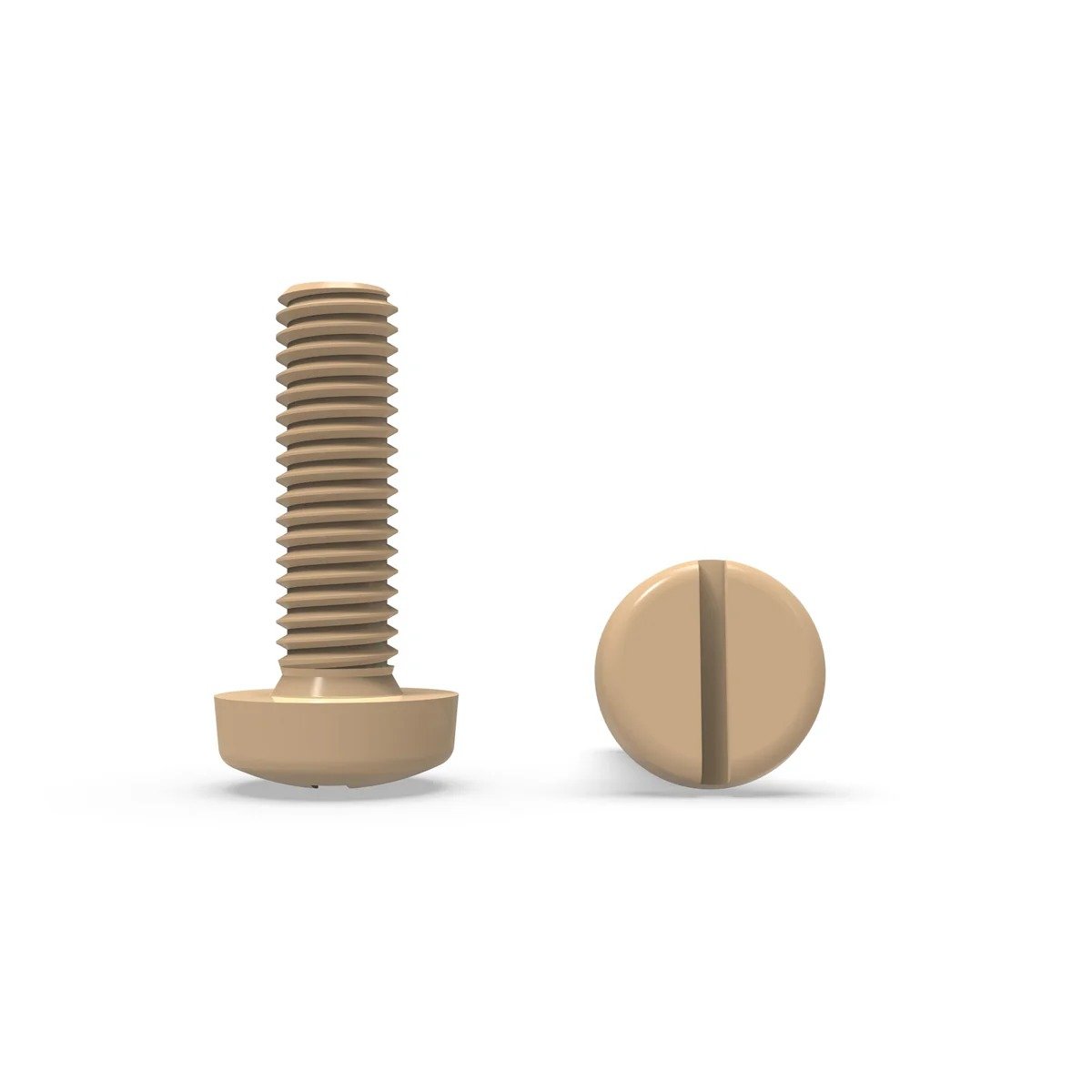

PA66 GF30 Slotted pan head screw

The PA66 GF30 slotted pan head screw is a high-performance polymer fastener featuring excellent mechanical properties thanks to its 30% glass fiber (GF30) reinforcement and slotted pan head design.

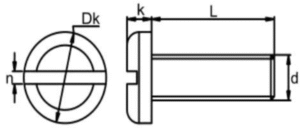

M Size: M2-M12

peek plastic material: Polyamide66(PA66 gf30)

product type: Pan Head Screws

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 GF30 Slotted pan head screw Overview

PA66 GF30 Slotted Pan Head Screw is a high-performance polymer fastener engineered by combining the chemical, electrical, and lightweight advantages of PA66 Nylon, the superior mechanical properties from 30% Glass Fiber (GF30) reinforcement, and the simple, load-distributing design of the Slotted Pan Head.

Key Features

The key advantages stem from the 30% Glass Fiber reinforcement:

- Exceptional Mechanical Strength: The glass fiber content provides a massive leap in GF30 Nylon Screw Strength, increasing tensile strength, rigidity, and hardness. This allows the screw to handle higher axial loads than standard nylon, positioning it as a viable PA66 GF30 Metal Replacement in non-critical applications.

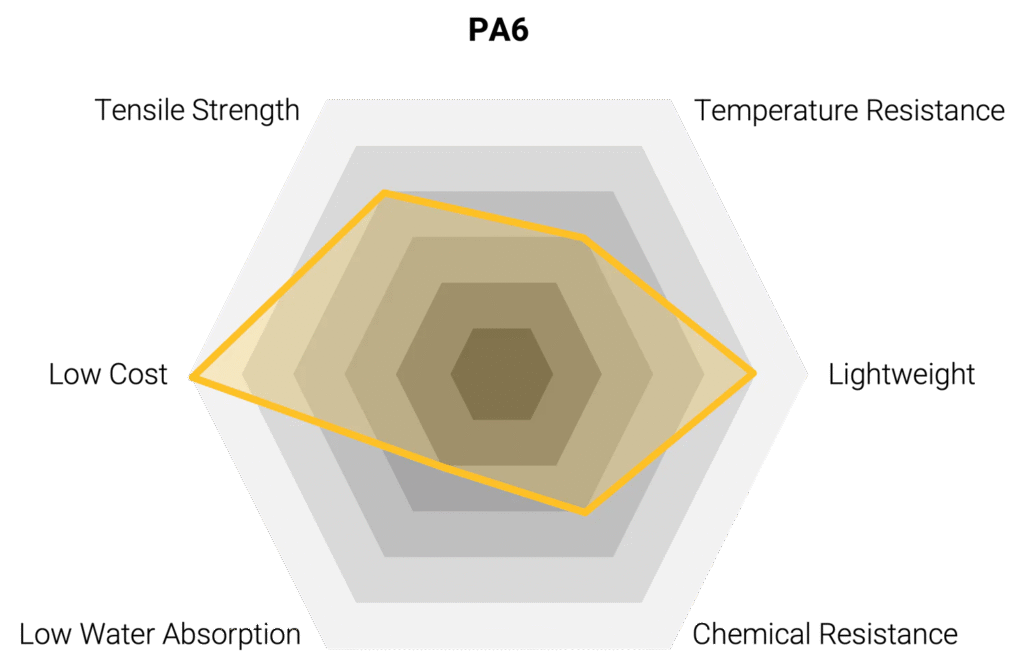

- Superior Thermal and Dimensional Stability: GF30 reinforcement significantly raises the Heat Deflection Temperature (HDT), offering PA66 GF30 High Temperature Screw performance. Crucially, the glass fibers reduce the base material’s inherent moisture absorption, boosting GF30 Screw Dimensional Stability and Creep Resistance under continuous load.

- Load Spreading (Pan Head): The Pan Head design offers a wide bearing area, preventing the screw from sinking into or damaging soft mating materials, which is vital when combining high GF30 Stiffness with sensitive substrates.

- Chemical & Electrical Isolation: It retains the core benefits of PA66, providing excellent Electrical Insulation and Chemical Resistance to fuels, oils, and greases (PA66 GF30 Chemical Resistance), essential in under-the-hood environments.

Key Polyamide Nylon (PA6) Properties

Pros and Cons Analysis

✅ Advantages (Pros)

- High Strength-to-Weight Ratio: Provides near-metal performance with the inherent lightweight advantage of plastic.

- Excellent Stability: Vastly superior dimensional stability and heat resistance compared to standard PA66, suitable for continuous high-temperature use.

- Corrosion Proof: Absolute immunity to rust and good resistance to many automotive fluids.

- Load Distribution: Pan Head geometry ensures a wide contact area, enhancing the clamping of softer components.

❌ Disadvantages (Cons)

- Increased Brittleness: The primary drawback of GF30 is the loss of material toughness, leading to a higher risk of brittle failure or cracking upon sudden impact or extreme over-tightening (GF30 Screw Brittle Failure).

- High Stripping Risk (Slotted Drive): The Slotted drive type has the lowest torque transmission efficiency. Despite the material’s strength, it remains highly vulnerable to tool cam-out and thread stripping if the GF30 Plastic Screw Torque Specs are not strictly adhered to.

- Abrasiveness: The glass fibers are abrasive and can cause wear on soft mating materials or the injection molds used to produce the screws.

- Cost: Significantly more expensive than standard nylon or low-grade metal screws.

Applications

The screw’s high strength and stability enable its use in more rigorous environments than standard nylon:

- Automotive Electrification (EV) and Under-Hood: Used as PA66 GF30 Automotive Fasteners for engine covers, radiator tanks, cooling system brackets, and battery pack accessories. The thermal stability and light weight are critical here.

- Industrial Controls and Power Electronics: Ideal for securing large terminal blocks, sensor housings, and circuit breaker components, leveraging high rigidity combined with electrical isolation (PA66 GF30 Electronic Components).

- Chemical and Fluid Handling: Used in pumps, filters, and valves where strong resistance to chemicals, excellent dimensional stability, and zero corrosion are mandatory (GF30 Fasteners Marine/Chemical).

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.