PA66 GF30 Slotted countersunk head screw

PA66 GF30 Slotted countersunk head screw is a specialized high-performance polymer fastener that combines the structural performance of glass fiber reinforced nylon with a countersunk design.

M Size: M2-M10

peek plastic material: Polyamide66(PA66 gf30)

product type: Countersunk Screws

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 GF30 Slotted countersunk head screw Overview

PA66 GF30 Slotted Countersunk Head Screw is a specialized high-performance polymer fastener. It combines the mechanical strength and thermal stability gained from 30% Glass Fiber (GF30) reinforcement with the aesthetic and aerodynamic benefit of a Countersunk Head (or Flat Head), which allows for a perfectly flush installation.

Key Features

he defining features are the fusion of high-performance material and specialized head geometry:

- Superior Mechanical Strength: The 30% glass fiber reinforcement drastically increases the material’s rigidity, shear strength, and overall load capacity (GF30 High Strength Plastic Screw). This allows the screw to manage higher clamping forces and shear loads than standard PA66.

- Thermal and Dimensional Stability: The GF30 composite exhibits a significantly raised Heat Deflection Temperature (relevant to PA66 GF30 High Temperature Screw), making it suitable for high-heat environments. The fibers minimize moisture-induced swelling, ensuring excellent GF30 Screw Dimensional Stability and superior Creep Resistance.

- Flush Installation: The Countersunk Head is designed to recess completely into a pre-drilled and countersunk hole, resulting in a flush surface finish (Flush Fastener GF30 Nylon). This is vital for aesthetic, ergonomic, and aerodynamic reasons.

- Non-Metallic Benefits: It retains the core PA66 advantages of electrical insulation, non-magnetism, and complete immunity to rust and corrosion, making it suitable for sensitive electronic or corrosive environments.

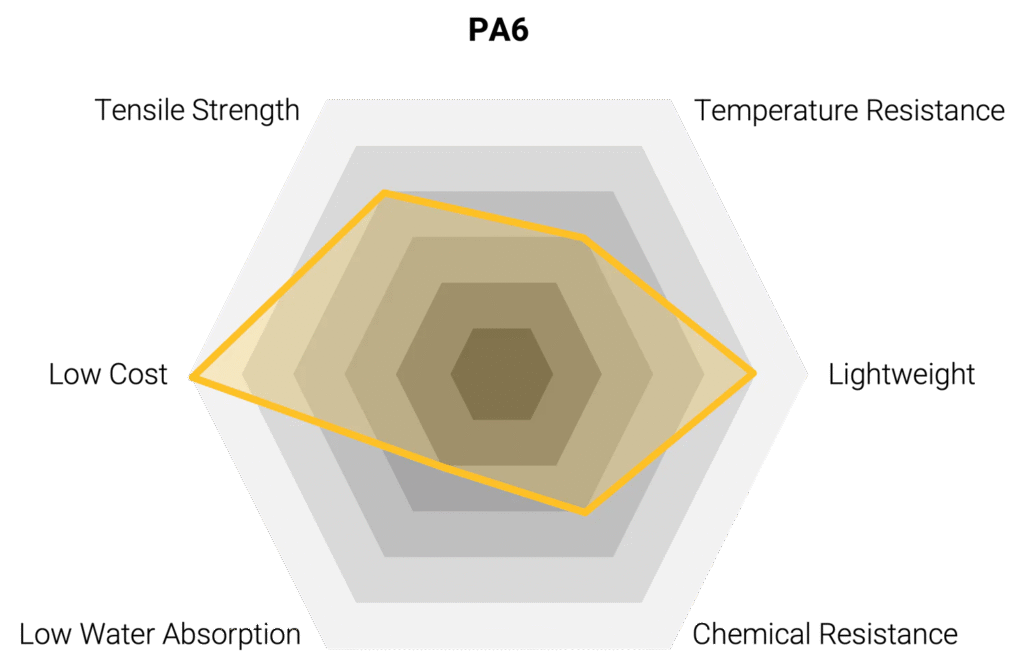

Key Polyamide Nylon (PA6) Properties

Applications

PA66 GF30 Countersunk Screws are used in applications where high strength is needed, but the surface must be smooth and unbroken:

- Automotive Exterior/Interior: Used for mounting trim, fairings, paneling, and aesthetic covers where a flush surface is essential for appearance or aerodynamics (PA66 GF30 Automotive Trim Fasteners).

- Electronic and Medical Equipment: Utilized in PA66 GF30 Electronic Enclosures and sensitive instruments where the non-conductive, non-magnetic properties must be combined with a smooth exterior finish (e.g., patient-facing parts).

- Industrial and Marine Paneling: Used for securing covers, access panels, or boat decking where fasteners are exposed to the environment and must not snag or cause injury (PA66 GF30 Marine Deck Fasteners).

- Structural Component Facing: Used to hold down parts that might experience moderate stress, leveraging the PA66 GF30 Metal Replacement capability while offering insulation.

Advantages&Disadvantages

✅ Advantages (Pros)

- Aesthetic and Aerodynamic: Provides a perfectly flush and smooth surface finish.

- High Strength Profile: GF30 reinforcement delivers excellent rigidity and load capacity for a plastic fastener.

- Stability: Superior dimensional stability and heat resistance compared to standard nylon.

- Non-Corrosive: Absolute immunity to rust and chemical corrosion.

❌ Disadvantages (Cons)

- High Stripping Risk (Double Risk): The Slotted drive is inherently prone to cam-out, and the conical shape of the countersunk head makes the material thinner at the edges, dramatically increasing the risk of head stripping or breakage (Countersunk Screw Head Stripping) if Plastic Screw Torque Specs are exceeded.

- Increased Brittleness: The GF30 material has lower toughness, leading to a higher risk of brittle failure (GF30 Slotted Screw Breakage) compared to unreinforced nylon.

- Requires Pre-Processing: Installation demands a precise countersink to be drilled into the mating material to achieve a flush fit, adding a step to the assembly process.

- Cost: Generally one of the more expensive nylon fasteners due to the GF30 material and complex head geometry.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.