PA66 GF30 Hex nuts

PA66 GF30 Hex nuts is an advanced engineered fastener with 30% glass fiber reinforced material (GF30), transforming the nut from a simple insulator into a high-performance semi-structural metal replacement.

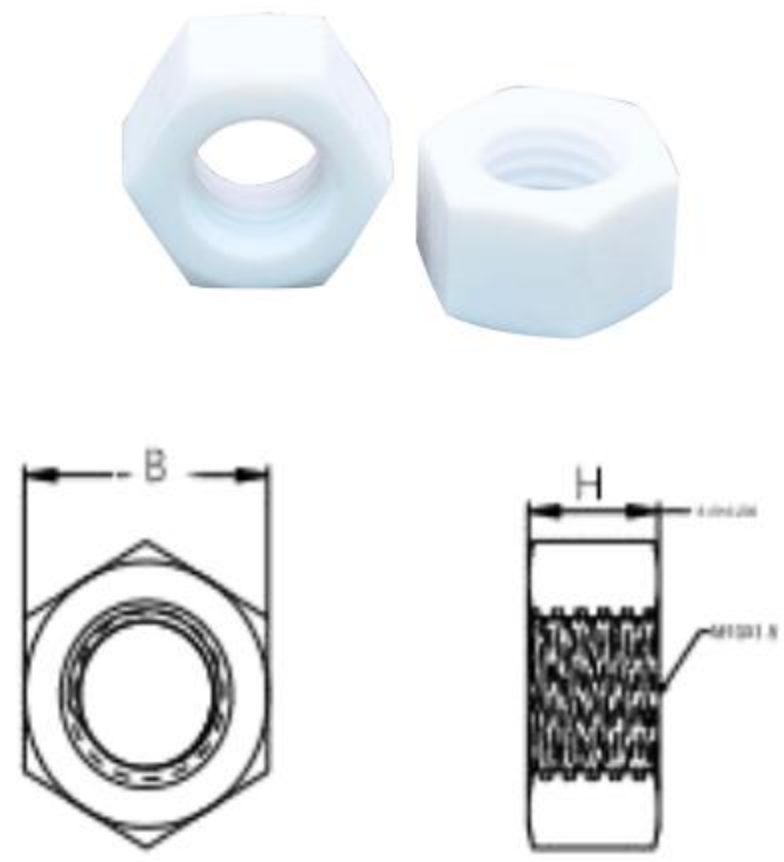

M Size: M3-M30

peek plastic material: Polyamide66(PA66)

product type: Nuts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 GF30 Hex nuts Overview

PA66 GF30 Hex nuts refers to a hexagonal nut made of PA66 (polyamide 66, commonly known as nylon 66) material reinforced with 30% glass fiber (GF30). This enhances the tensile strength, rigidity, and heat resistance of PA66, and improves its dimensional stability.

Key Features

The inclusion of glass fibers fundamentally alters the mechanical properties of the fastener:

- Significantly Increased Strength and Stiffness (GF30 Advantage): The glass fiber reinforcement can nearly double the tensile strength and triple the stiffness (Young’s Modulus) compared to unreinforced PA66. This allows the nut to handle much higher pre-loads and stress, making it a viable High Strength Plastic Nut.

- Superior Thermal Performance: The GF30 composite exhibits a much higher heat deflection temperature (HDT). This is critical for the nut’s integrity in environments like an Automotive Engine Bay Nut, where temperatures routinely exceed the limits of standard Nylon.

- Excellent Dimensional Stability: The glass fibers act as an internal scaffolding, stabilizing the polymer matrix. This drastically reduces the hygroscopic swelling associated with PA66 and improves the nut’s resistance to creep failure under sustained load over time.

- Chemical and Electrical Benefits Retained: Like its unreinforced counterpart, the PA66 GF30 nut remains non-corrosive and acts as an effective Electrical Insulating Nut, separating dissimilar metals and preventing galvanic corrosion.

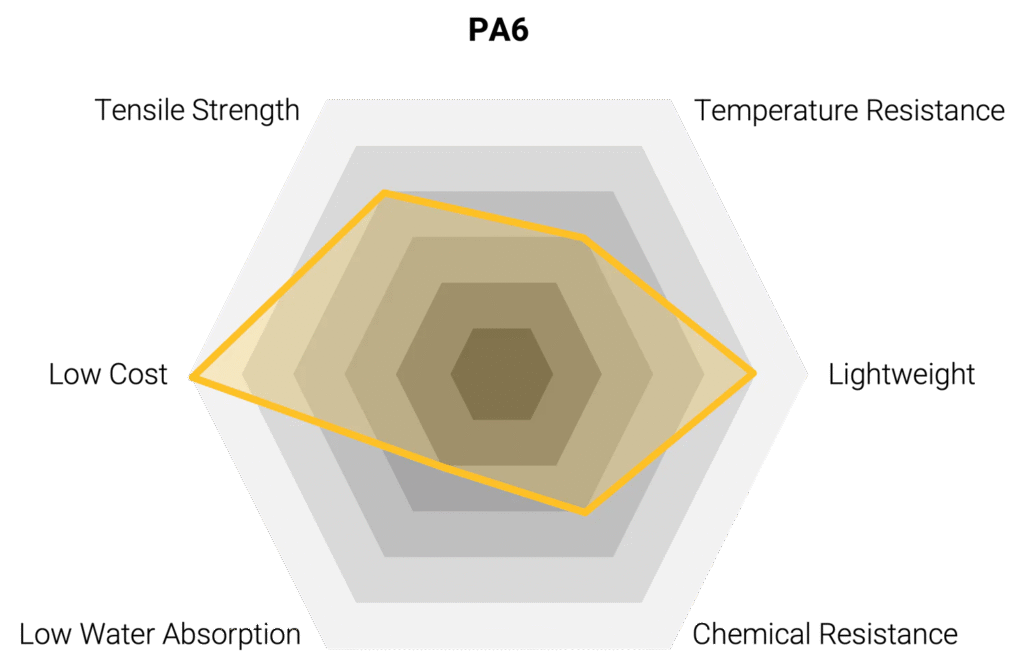

Key Polyamide Nylon (PA6) Properties

Applications

PA66 GF30 Hex Nut excels in applications requiring a balance of strength and non-metallic benefits:

- Automotive and Aerospace: Used for securing non-structural components like sensor mounts, air ducts, fluid reservoirs, and light brackets in areas exposed to moderate heat and vibration. This is a common Metal Replacement Nut in modern vehicles to reduce overall mass.

- Industrial Equipment: Applied in the assembly of pumps, filters, conveyors, and small machinery, particularly where electrical components must be isolated but require a robust fastener.

- Outdoor and Marine Structures: Ideal for high-stress outdoor assemblies where UV exposure, moisture, and saltwater demand both structural integrity and absolute immunity to rust.

- High-End Electronics and Telecom: Used for mounting PCBs and chassis components in systems that generate heat, ensuring stability while maintaining the necessary electrical isolation.

Pros&Cons

✅ Advantages (Pros)

- High Strength: Handles significantly greater torque and tensile loads than standard Nylon, allowing for higher assembly preload.

- Higher Heat Resistance: Maintains strength and form factor at elevated temperatures, expanding its operating range.

- Excellent Stability: Exhibits superior PA66 GF30 Dimensional Stability and exceptional Creep Resistance compared to standard PA66.

- Corrosion Proof: Absolute resistance to rust, making it ideal for marine and chemical exposure.

- Electrical Isolation: Provides safe electrical separation and prevents galvanic corrosion.

❌ Disadvantages (Cons)

- Increased Brittleness: The primary drawback is lower impact strength than unreinforced PA66, making it more susceptible to sudden brittle failure or cracking.

- Tool and Part Abrasion: The hard glass fibers can be abrasive to the threads on the mating part or on assembly tools over repeated use, reflected in searches for Glass-filled Nylon Abrasion.

- Higher Cost: Significantly more expensive than standard Nylon, often leading to a cost trade-off analysis compared to steel.

- Assembly Caution: Requires precise knowledge of PA66 GF30 Nut Torque Value; while its strength is higher, improper over-tightening can still lead to thread stripping or failure.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.