PA66 GF30Pan Head Screws-Cross Recessed Phillips

PA66 GF30Pan Head Screws-Cross Recessed Phillips is a high-performance polymer fastener with 30% glass fiber reinforcement (GF30). It possesses non-metallic properties (insulation, corrosion resistance).

M Size: M2-M12

peek plastic material: Polyamide66(PA66 gf30)

product type: Pan Head Screws

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

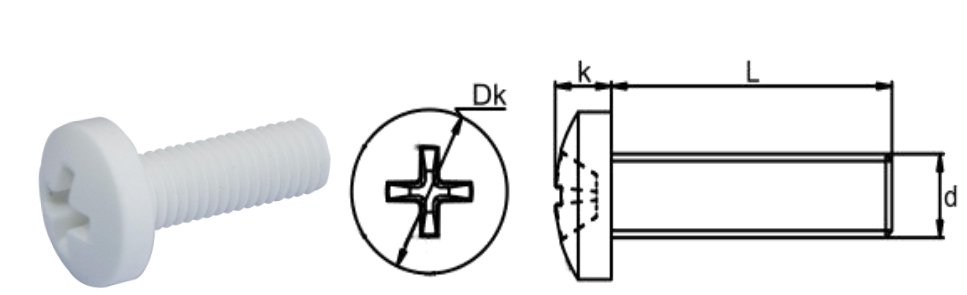

Product Drawing

PA66 GF30Pan Head Screws-Cross Recessed Phillips is a robust polymer solution designed to bridge the performance gap between standard nylon and metal. The 30% glass fiber (GF30) reinforcement is specifically included to manage higher stress, higher temperatures, and improve long-term joint stability.

Key Features

The inclusion of GF30 transforms the fastener’s capabilities while retaining the Phillips drive’s assembly efficiency and the Pan Head’s load-spreading function:

- Significantly Enhanced Strength and Stiffness: The glass fibers lead to a drastic increase in tensile strength, shear strength, and rigidity. This allows the screw to handle higher clamping forces and axial loads, making it a powerful High Strength Plastic Screw.

- Superior Thermal Performance and Creep Resistance: The reinforcement elevates the Heat Deflection Temperature (HDT), offering PA66 GF30 High Temperature Screw performance. More importantly for long-term joints, the fibers provide excellent PA66 GF30 Creep Resistance, meaning the joint is less likely to loosen under continuous stress.

- Improved Dimensional Stability: GF30 minimizes the moisture absorption inherent to PA66, ensuring better GF30 Nylon Dimensional Stability across varying humidity and temperature conditions.

- Retained Non-Metallic Benefits: The screw remains an excellent electrical insulator, is completely non-corrosive, and provides the necessary Lightweight Advantage for modern assembly.

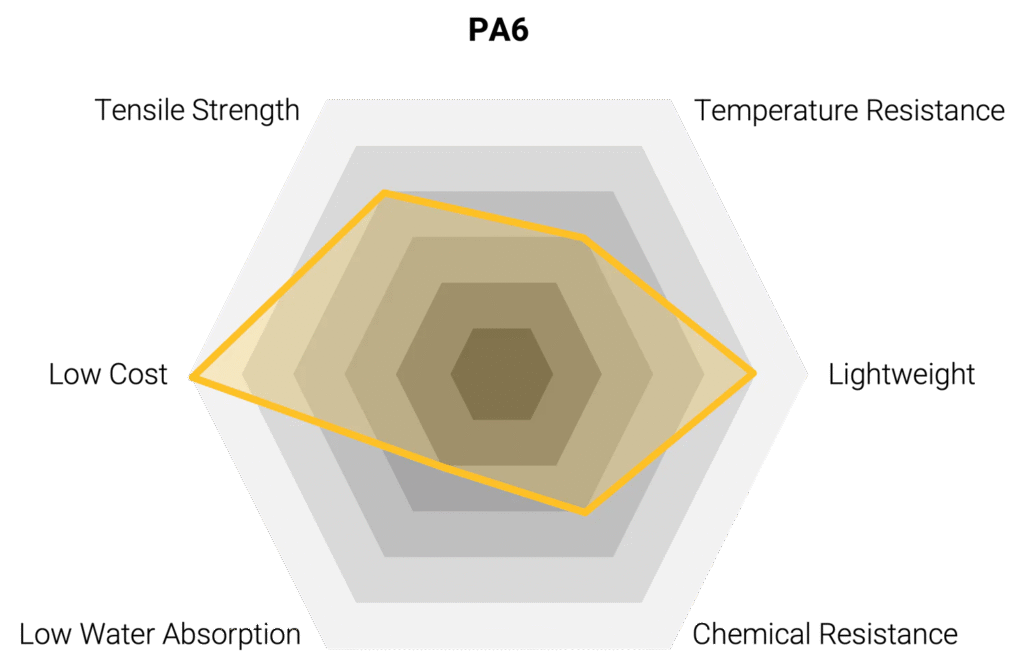

Key Polyamide Nylon (PA6) Properties

Pros and Cons Analysis

✅ Advantages (Pros)

- High Load Capacity: Offers a significant increase in strength and rigidity over unreinforced PA66, allowing for higher assembly Torque Specs GF30.

- Superior Stability: Excellent Creep Resistance and Dimensional Stability make the joint highly reliable over the long term, especially under thermal cycling.

- Heat Resistance: Suitable for higher continuous operating temperatures than standard nylon.

- Efficiency and Protection: The Phillips drive allows for fast assembly, and the Pan Head ensures good Load Distribution on soft surfaces.

- Non-Corrosive and Insulating: Absolute immunity to rust, saltwater, and galvanic corrosion.

❌ Disadvantages (Cons)

- Increased Brittleness: The primary trade-off is the loss of material toughness, increasing the risk of brittle failure or cracking upon sharp impact or extreme over-tightening (Glass-filled Nylon Brittleness).

- High Stripping Risk (Phillips Drive): The combination of a highly efficient (but easy to cam-out) Phillips drive and the hard, rigid GF30 material means that over-torquing leads immediately to Nylon Phillips Screw Stripping Risk or head damage.

- Abrasion: The glass fibers can be abrasive to the mating thread (if plastic or soft metal) upon repeated assembly/disassembly.

- Cost: Significantly more expensive than standard PA66 or low-grade metal screws.

Applications

The screw is specialized for medium-load applications in environments where heat, vibration, and non-conductivity must coexist with elevated mechanical performance:

- Automotive Engine Bay: Used extensively as PA66 GF30 Automotive Fasteners for securing radiator mounts, covers, sensor brackets, and fluid tanks, leveraging its high temperature and chemical resistance.

- High-End Electronics and Power Supplies: Applied in systems that generate heat, where the screw must provide robust fastening and structural integrity while maintaining electrical isolation (PA66 GF30 Electronic Components).

- Appliances and HVAC: Used in assemblies exposed to fluctuating heat and moisture, where long-term stability and resistance to chemicals (like cleaning agents or oils) are required.

- General Metal Replacement: Used in engineering projects specifically targeting mass reduction, where the screw serves as a reliable GF30 Screw Metal Replacement in semi-structural applications.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.