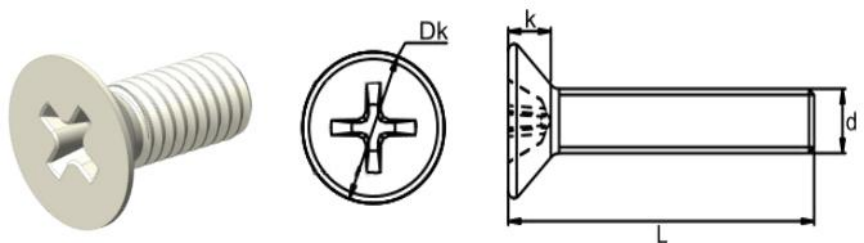

PA66 GF30 Countersunk Screws-Cross Recessed Phillips

PA66 GF30 Countersunk Screw – Cross Recessed Phillips represents the highest-performance, most specialized polymer countersunk fastener

M Size: M2-M10

peek plastic material: Polyamide66(PA66 gf30)

product type: Countersunk Screws

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 GF30 Countersunk Screws-Cross Recessed Phillips Overview

PA66 GF30 Countersunk Screws-Cross Recessed Phillips is the choice for engineers who require a non-protruding, corrosion-proof fastener that offers significantly higher mechanical performance than standard polymer screws. The 30% Glass Fiber reinforcement (GF30) is essential for achieving these higher metrics.

Key Features

The screw’s performance profile is determined by its GF30 reinforcement and Countersunk geometry:

- Superior Mechanical Strength and Rigidity: The glass fibers provide a dramatic increase in tensile strength, rigidity, and shear strength. This allows the screw to manage higher axial loads and significantly reduce the risk of stripping the thread or body of the screw itself (when correctly torqued).

- Excellent Thermal and Creep Stability: GF30 elevates the Heat Deflection Temperature (HDT) and, crucially, minimizes the material’s susceptibility to creep—the permanent deformation under sustained load. This ensures the joint maintains its preload better than standard nylon, even under heat.

- Dimensional Reliability: The reinforcement stabilizes the PA66 against moisture absorption, ensuring excellent GF30 Nylon Dimensional Stability for reliable performance in fluctuating humidity and temperature.

- Flush Finish (Aesthetic and Functional): The Countersunk head allows the screw to recess fully into the mating material, resulting in a smooth, continuous surface. This is essential for safety, appearance, and aerodynamic efficiency.

- Non-Metallic Benefits: The screw retains its non-magnetic, electrical insulating, and absolute corrosion-proof properties.

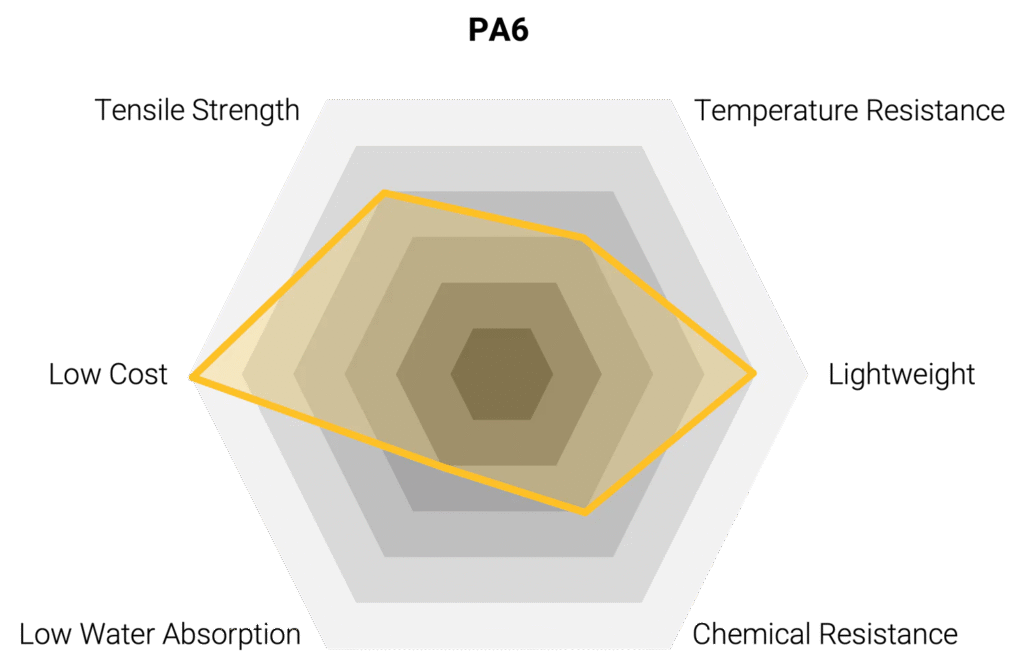

Key Polyamide Nylon (PA6) Properties

Applications

This screw is specialized for demanding, semi-structural assemblies where a smooth surface is mandatory:

- Automotive Exterior and Interior: Used as PA66 GF30 Automotive Trim Screw for securing exterior fairings, body panels, and aerodynamic elements where strength, heat resistance, and a flush surface are non-negotiable.

- Electric Vehicle (EV) Components: Applied in battery housings, underbody panels, or thermal management covers (PA66 GF30 EV Fasteners Flush), where mass reduction, insulation, and high rigidity are required alongside a smooth surface for protection.

- Industrial and Medical Housings: Used for high-end electronic or clean-room equipment where structural integrity, non-conductivity, and a dirt-preventing, flush exterior are necessary.

- General Metal Replacement: Chosen in projects aiming to replace metal fasteners to reduce both weight and galvanic corrosion risk, specifically where the joint requires higher load capacity than standard plastic.

Advantages&Disadvantages

✅ Advantages (Pros)

- Highest Strength Plastic Flush Screw: Offers the best combination of mechanical strength and stability among non-metallic countersunk options.

- Superior Joint Stability: Excellent Creep Resistance and Dimensional Stability ensure the joint stays tight, even in challenging thermal environments.

- Aesthetic and Functional Flushness: Achieves a perfectly smooth surface, essential for safety and aerodynamics.

- Heat Resistant: Suitable for higher continuous operating temperatures than unreinforced PA66.

- Corrosion Proof and Insulating: Eliminates rust and galvanic corrosion risk completely.

❌ Disadvantages (Cons)

- Critical Stripping Risk (Highest): This design is highly susceptible to failure. The Phillips drive is prone to cam-out, and the GF30 material is prone to brittle failure and cracking under stress. The risk of GF30 Countersunk Head Stripping is extremely high if Torque Specs are exceeded.

- Brittleness: The primary trade-off for strength is toughness. The material is more brittle and susceptible to impact failure compared to standard PA66.

- Requires Pre-Processing: Installation demands a precisely drilled countersink in the mating material to achieve the necessary flush fit.

- High Cost: This is one of the most expensive nylon fasteners due to the GF30 material and specialized geometry.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.