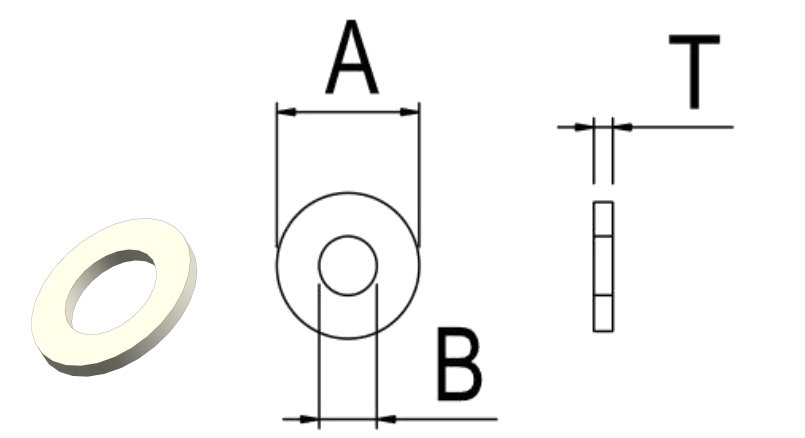

PA66 GF30 Flat washer

PA66 GF30 flat washer (30% glass fiber reinforced polyamide 66) is an industrial-grade component for applications requiring non-metallic properties (insulation, corrosion resistance) as well as high rigidity, high temperature resistance, and excellent stability.

M Size: M3-M30

peek plastic material: Polyamide66(PA66)

product type: Washers

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 GF30 Flat washer Overview

PA66 GF30 Flat washer (30% glass fiber reinforced polyamide 66)are robust and durable plastic fasteners designed to withstand large axial loads and maintain joint integrity in environments where standard nylon materials fail due to high temperatures or creep.

Key Features

PA66 GF30 Flat Washer’s properties are defined by the reinforcement:

- Superior Mechanical Rigidity: The glass fibers drastically increase the modulus of elasticity (stiffness) of the washer, making it a true High Strength Plastic Washer. This ensures the washer distributes the clamping load over a wide area without deforming or yielding, especially when used under high torque (relevant to GF30 Washer Torque Specs).

- Excellent Creep Resistance: The biggest advantage over standard PA66 is the enhanced PA66 GF30 Washer Creep Resistance. This ensures the joint maintains its preload and clamping force over extended periods, even under constant stress and elevated temperatures.

- High Thermal and Dimensional Stability: GF30 elevates the material’s heat deflection temperature (HDT), offering GF30 Washer High Temperature performance. Furthermore, the fibers resist moisture uptake, resulting in excellent PA66 GF30 Washer Dimensional Stability.

- Retained Non-Metallic Benefits: It remains electrically insulating (PA66 GF30 Electrical Insulating Washer), completely non-corrosive, non-magnetic, and provides a significant lightweight benefit.

Applications

PA66 GF30 Flat Washer is used in demanding, medium-to-high load assemblies where non-metallic properties are crucial:

- Automotive Engine Bay: Used in PA66 GF30 Washer Automotive applications to secure engine sensors, fluid lines, and electrical connections. Its high-temperature and chemical resistance are critical here.

- Industrial Equipment and Machinery: Applied in pumps, valves, and heavy-duty sensors where vibration, chemicals, and the need for structural stability coexist with the requirement for electrical isolation.

- High-End Electronics and Power Devices: Used as a robust Reinforced Nylon Spacer Washer under bolt heads to prevent crushing sensitive components while providing necessary electrical isolation and thermal stability.

- Metal Replacement: Employed in engineering projects aiming for weight savings and corrosion elimination, often serving as a GF30 Washer Metal Replacement in corrosive outdoor or marine settings (PA66 GF30 Washer Marine).

Advantages&Disadvantages

✅ Advantages (Pros)

- Reliable Electrical Isolation: Safely separates electrical components and prevents galvanic corrosion between dissimilar metals.

- Corrosion Proof: Absolute immunity to rust, excellent resistance to many common chemicals and solvents.

- Cost-Effectiveness: High-volume molding makes it highly economical (PA66 Washer Price per 1000) compared to specialty metal washers.

- Lightweight and Durable: Provides weight reduction and good resistance to abrasion and impact.

- Damping: Absorbs shock and reduces assembly noise.

❌ Disadvantages (Cons)

- Moisture Sensitivity (Hygroscopic): PA66 absorbs moisture from the atmosphere. This affects Nylon Washer Dimensional Stability, potentially causing the washer to swell slightly and changing its mechanical properties.

- Limited Torque/Clamping Force: It has a much lower modulus than metal. Applying excessive torque risks permanent deformation or “dishing” the washer.

- Creep Tendency: Under high, constant pressure, PA66 is susceptible to PA66 Washer Creep Resistance failure, meaning it can permanently deform over time, leading to joint loosening.

- UV Sensitivity: Without special UV stabilizers, Nylon Washer UV Resistance is poor, leading to degradation and yellowing upon prolonged exposure to sunlight.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.