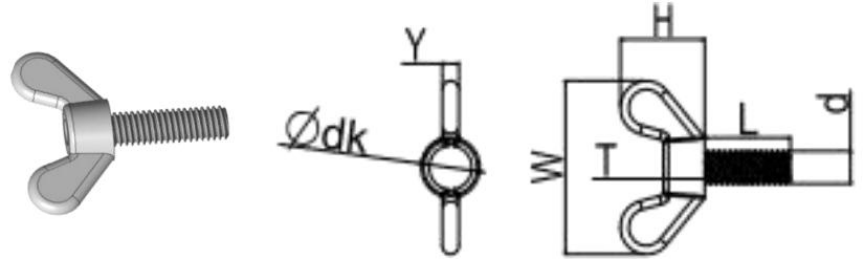

Butterfly screw

butterfly screw (also widely known as a wing screw or wing bolt) is a specialized type of mechanical fastener designed for easy, tool-free adjustment and fastening.

M Size: M5-M6

peek plastic material: PA66/PP/POM

COLOR:Naturalcolor/pink/blue/orange.Othercolorscanbe Customizable

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

Overview of Butterfly Screws

butterfly screw—also known as a wing screw, wing bolt, wing nut screw, Thumb screw, or simply screw butterfly—is a fastener designed for tool-free tightening and loosening. The name comes from its two extended “wings,” which provide strong grip leverage, allowing users to turn the screw by hand without using a wrench or screwdriver.

It is recommended to use screws and nuts of the same material.

Key Features

The defining feature of the butterfly screw is its head design, which is shaped to maximize manual torque application. The term wing bolt butterfly screw is often used to capture the essence of this design.

- Tool-free manual operation: The defining characteristic of the butterfly screw is its winged head, allowing users to tighten or release it easily with fingers alone.

- High Grip Leverage: The broad wings provide increased torque compared to a standard Thumb screw, making it easier to fasten without tools.

- Material Versatility : Commonly available in corrosion-resistant materials like Stainless Steel for marine and outdoor use, or economical materials like Zinc-Plated Steel. Lightweight versions often use nylon or plastic.

- Versatile Thread Types: Frequently referred to as wing screw or wing bolt due to the head’s shape. Butterfly bolts usually imply a heavier-duty or larger diameter version.

- Wing bolts: The lower end is a threaded rod and requires a nut.

- Wing screws: The lower end has machine or self-tapping threads and can be screwed directly into pre-made holes in metal or plastic.

- Wide Range of Sizes: In industrial settings, engineers may refer to size charts such as the butterfly valve cap screw chart when matching butterfly screws with valve assemblies.

Butterfly Screw

Applications

The convenience of the wing bolt butterfly screw makes it a preferred choice in applications requiring rapid assembly, disassembly, or frequent adjustment.

Consumer Electronics and Mounting: Used extensively in brackets and stands that need quick positioning changes. This includes camera tripods, microphone stands, and securing adjustable parts on displays. A common search relates to securing mounting hardware: butterfly screws for tv mount.

Furniture and Fixtures: Ideal for ready-to-assemble (RTA) furniture, trade show displays, and shelving that requires non-permanent, tool-free construction.

Anchoring in Hollow Walls: A specific, but mechanically distinct, category of product utilizes the wing concept for expansion in hollow cavities. Searches for drywall butterfly screws, butterfly screws for drywall, or butterfly screw for drywall refer to these toggle-style anchors whose wings deploy behind the wall to secure a hold (not the thread-style screw itself).

Industrial/Valves: A related, highly specific industrial search is butterfly valve cap screw chart, referring to the specific fasteners used on the bonnets or caps of industrial butterfly valves, where precise torque and sealing are required.

Hobby and Test Fixtures: Fastening access panels, covers, or components in laboratory and prototyping setups that require frequent inspection or modification.

Advantages

✅Advantages (Pros)

The primary benefit of the butterfly screw lies in its exceptional ease of use and tool-free functionality.

Tool-Free Operation: The large wings extending from the head provide an excellent grip, allowing the user to tighten and loosen the fastener quickly using only their hands. This eliminates the need for any tools (screwdrivers, wrenches), dramatically simplifying field assembly and adjustment.

Speed of Assembly and Disassembly: For applications requiring frequent component changes, maintenance access, or quick setup (e.g., stage lighting, trade show displays, camera equipment), the wing screw allows for rapid adjustments, saving significant time.

Accessibility: They are the ideal choice for fasteners located in areas that may be difficult to reach with standard tools, relying instead on manual dexterity.

Cost-Effective Assembly: By eliminating the need for specific tools or specialized labor during assembly, the overall cost and complexity of the product installation are reduced.

❌Disadvantages (Cons)

The same design feature that grants convenience also imposes mechanical limitations on the butterfly screw.

Low Torque Limitation: The maximum clamping force (torque) achievable is strictly limited to the strength of the human hand. This makes the wing bolt unsuitable for high-load, heavy-duty, or critical structural applications where specific, high-tension preload is required.

Vulnerability to Loosening: Due to the low installation torque, butterfly screws are highly susceptible to loosening when subjected to prolonged vibration or cyclical mechanical stress, potentially requiring additional locking hardware (like lock washers).

Bulk and Space Consumption: The large, projecting wings occupy more physical space compared to conventional screw heads (like socket heads or hex heads). This makes them impractical for use in confined or tightly-packed assemblies.

Risk of Snagging and Damage: The exposed wings can be easily snagged, bent, or broken if the equipment is mishandled, dropped, or operated in a high-traffic environment.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.